Permanent magnet for motor, motor housing and motor device

A technology for permanent magnets and motors, applied in the field of permanent magnets, can solve problems such as poor corrosion resistance, difficulty in applying heat resistance, poor heat resistance of bisphenol A epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

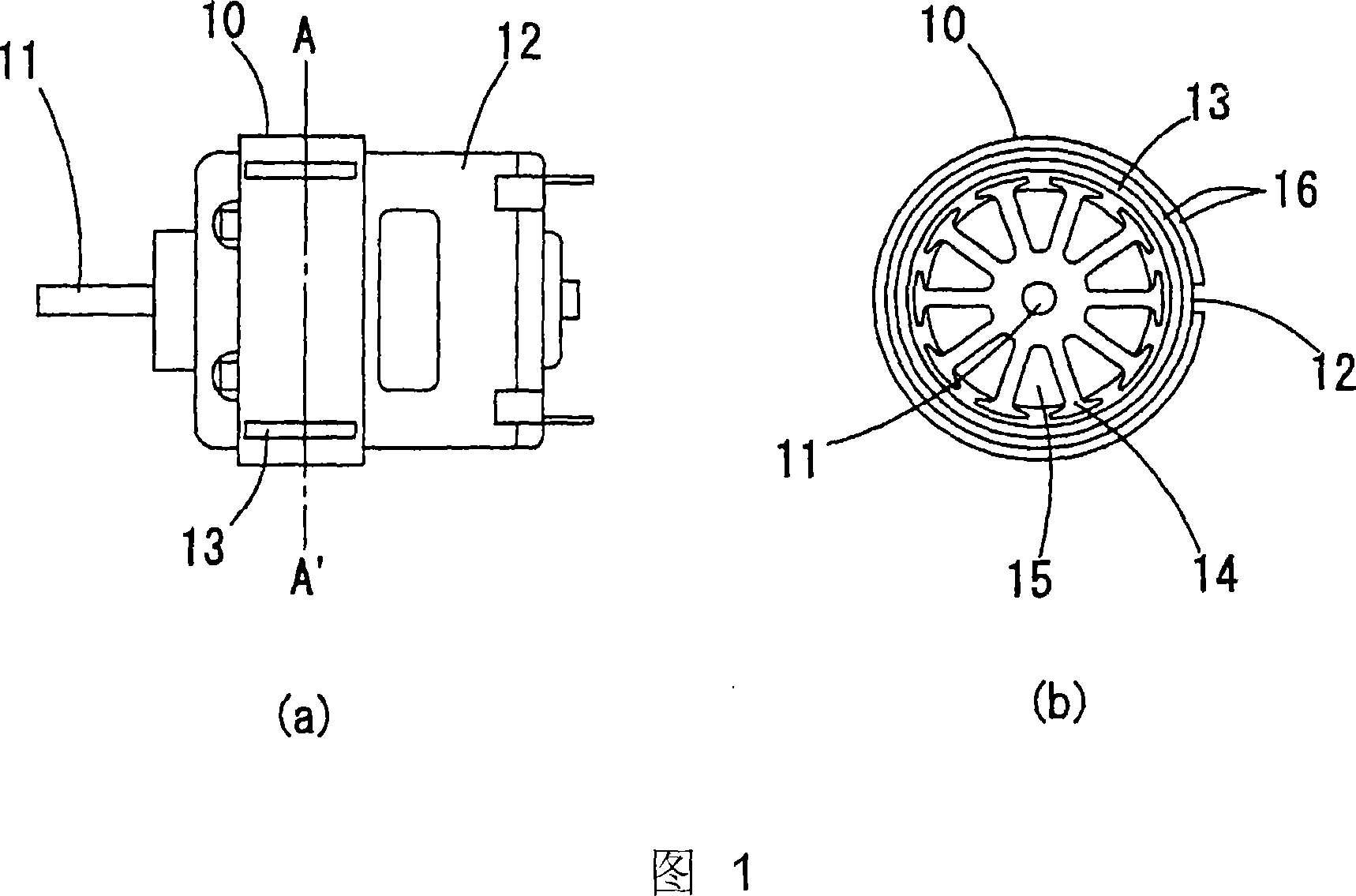

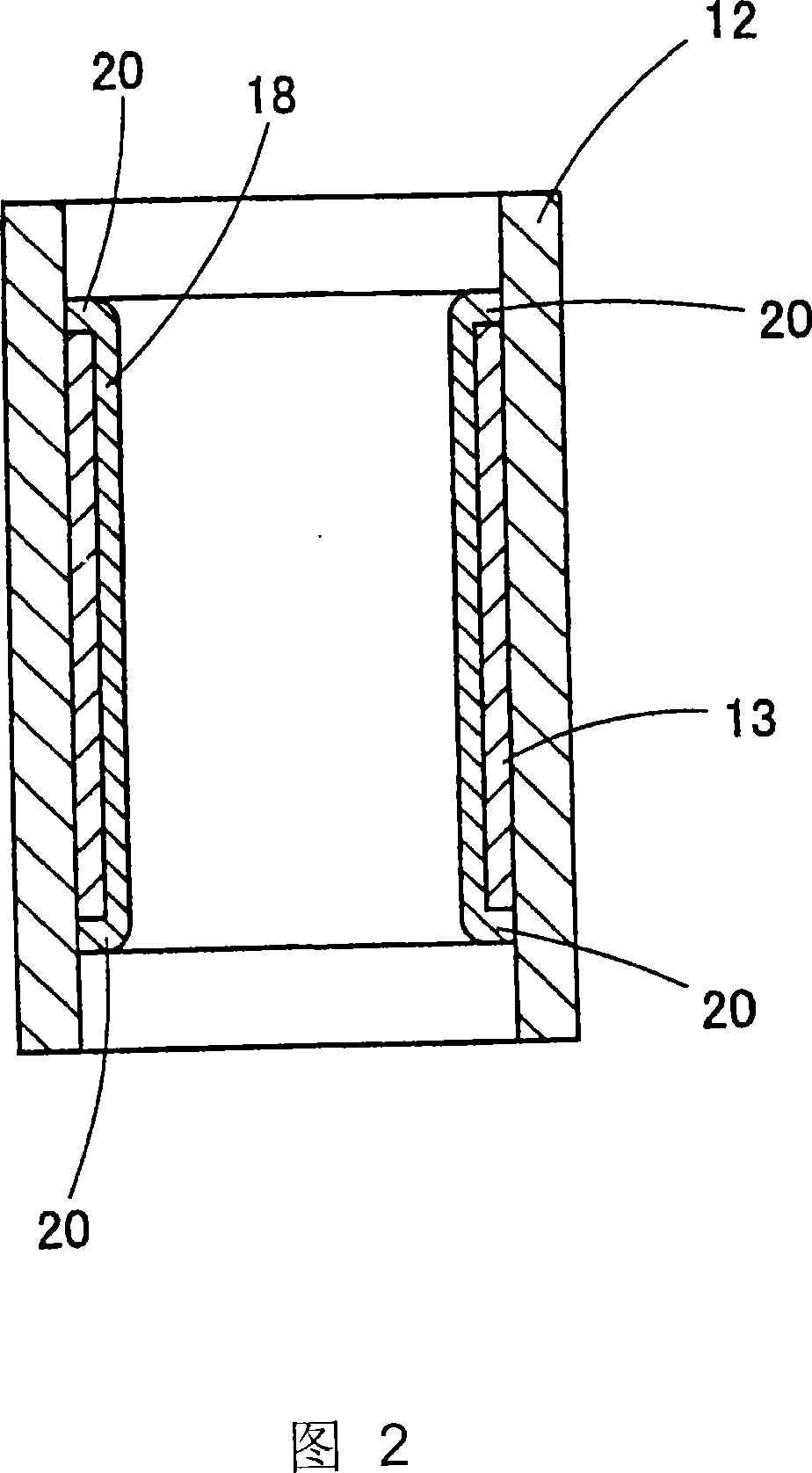

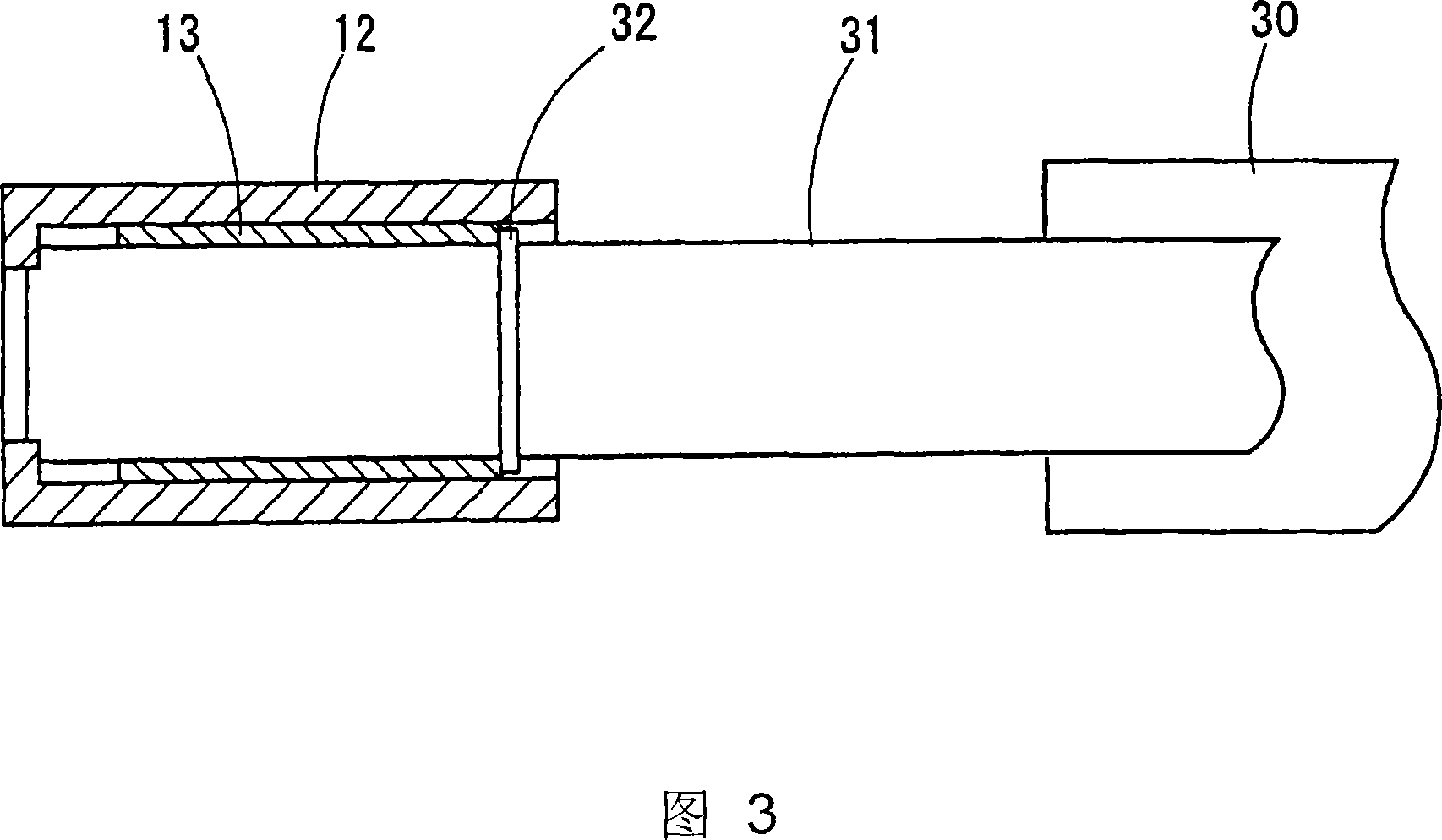

[0096] FIG. 1(a) and FIG. 1(b) show an example of the motor device according to this embodiment. Figure 1(a) is a side view, and Figure 1(b) is a cross-sectional view of AA'. Compared with conventional motor devices, the motor device shown in this embodiment has the characteristics of downsizing and high torque, and can prevent deterioration of motor characteristics over time when used in an organic solution. The motor device shown in this embodiment has the following configuration. An anisotropic rare-earth bonded magnet 13 having a hollow cylindrical shape as a permanent magnet is provided in the casing 12 and the inner peripheral portion of the casing 12; in addition, a rotor 14 forming an electromagnetic rotating body is provided in the central portion. A coil 15 is wound around the rotor 14, and a rotary shaft 11 protrudes from the center of the rotor 14; and an outer yoke 10 is provided for preventing loss of magnetic flux. Here, it should also be emphasized that the a...

experiment example

[0128] In the following, various characteristics of anisotropic rare earth bonded magnets are measured and analyzed.

[0129] The binder in the anisotropic rare earth bonded magnet of the present invention uses phenol novolac epoxy resin, while the binder in the previous bonded magnet uses bisphenol A epoxy resin. In this embodiment, firstly, the viscosity characteristics of phenol novolac epoxy resin and bisphenol A epoxy resin with respect to temperature change were measured and analyzed respectively. The result is shown in Figure 5. From the measured results, it can be seen that the minimum (low) value of the viscosity of the phenol novolac epoxy resin used in the present invention is one digit smaller than the minimum (low) value of the viscosity of the bisphenol A epoxy resin. Moreover, at this time, the temperature of phenol novolac epoxy resin is much lower than that of bisphenol A epoxy resin. If the magnetization and orientation treatment of the magnetic powder is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic loss | aaaaa | aaaaa |

| magnetic loss | aaaaa | aaaaa |

| dimension change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com