Steel pipe for air bag inflator and method for production thereof

A manufacturing method and inflator technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of lack of high strength and toughness, and achieve the effects of excellent low temperature toughness, improved fuel cost, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

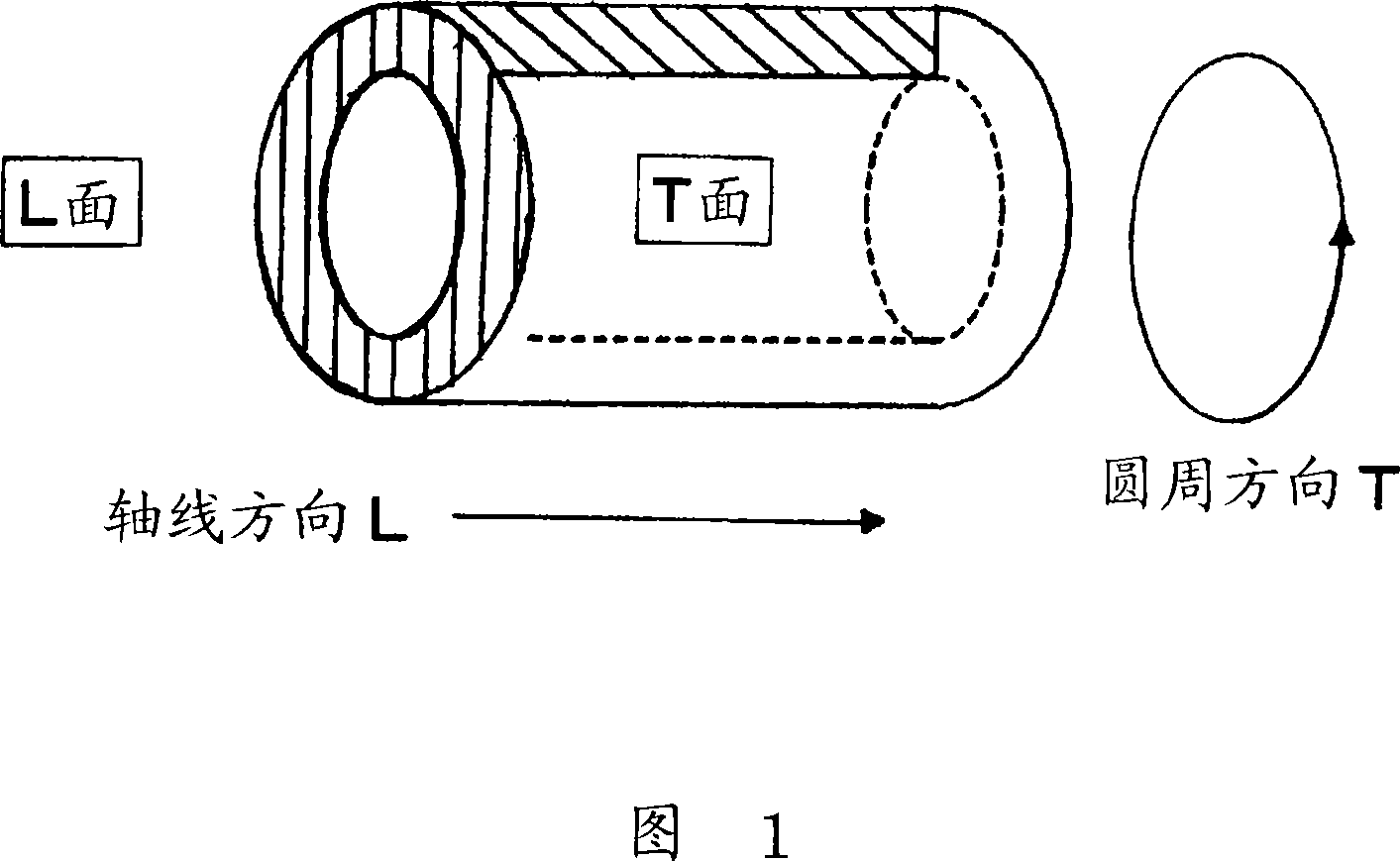

Image

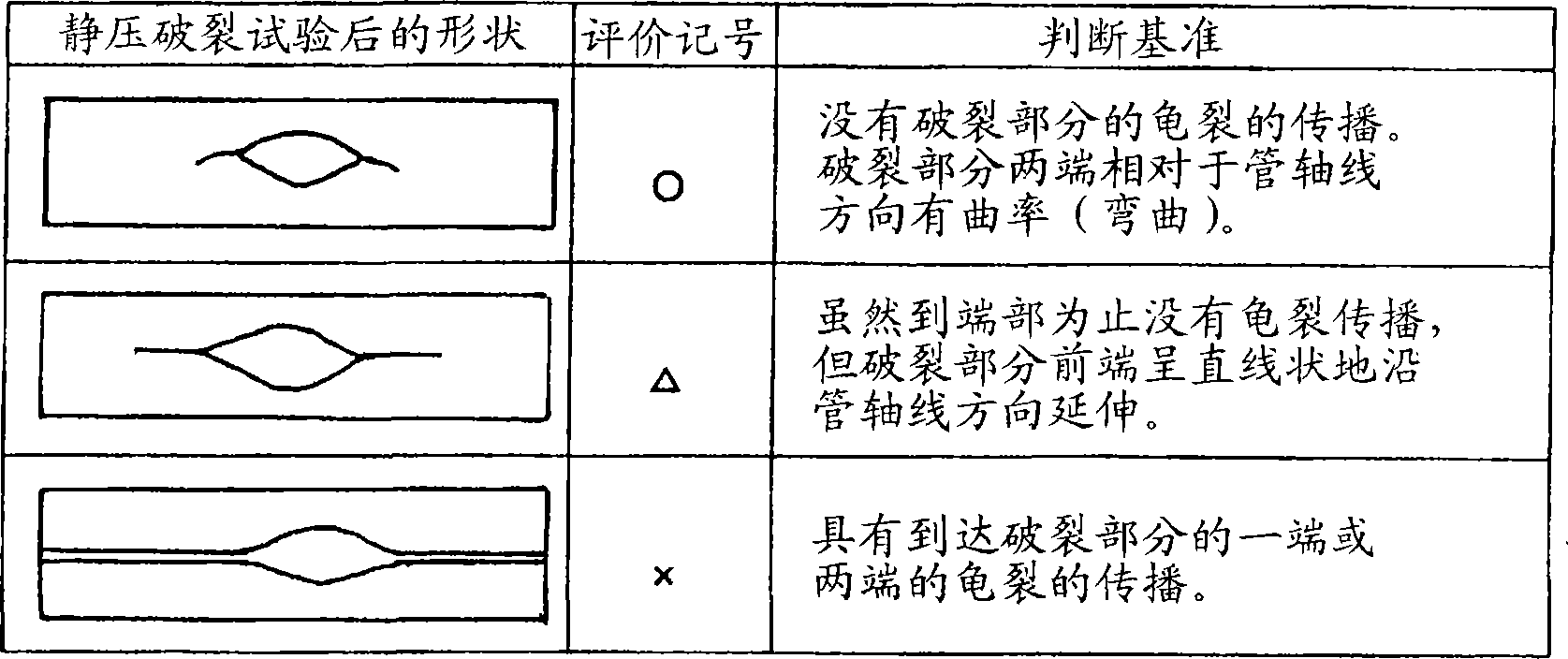

Examples

Embodiment 1

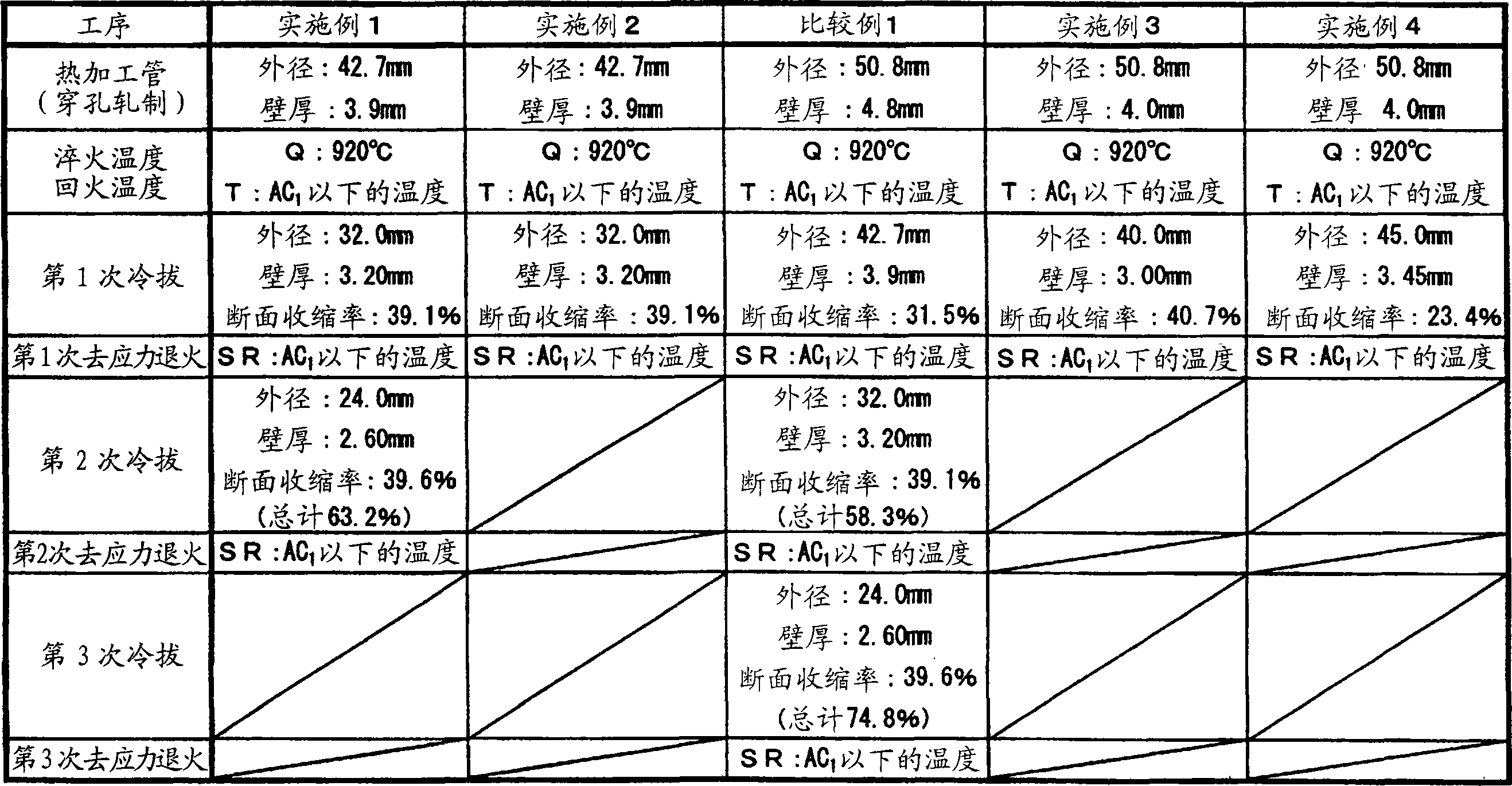

[0087] Using a steel billet having the steel composition shown in Table 1, after heating to 1250°C, it is pierced and rolled by the usual Mannesmann piercing mill-mandrel mill method, thereby hot-working the steel pipe to the outer diameter The nominal size of 42.7mm × wall thickness 3.9mm is used to manufacture seamless steel pipes as tube blanks. Among the steel compositions shown in Table 1, the values of Nos. 17 to 19 (Mn+40×Ti) are examples out of the range specified by the present invention, and Nos. 20 and 21 are examples in which the Cr content is out of the range. These They are all steel.

[0088] As shown in Table 2, after heating each tube billet with a common walking heating furnace (the temperature rise rate is 0.3°C / sec, and the atmosphere is the atmosphere) for 10 minutes to 920°C, water-cooled water quenching (in Table 2 is used Q represents the heating temperature), then use a walking furnace (the atmosphere is the atmosphere) in the Ac 1 Tempering was pe...

Embodiment 2

[0090] Although steel pipes were produced in the same manner as in Example 1, as shown in Table 2, the second drawing out of the two cold drawing performed in Example 1 and the subsequent stress relief annealing were not performed. Therefore, the section reduction rate of cold drawing is 39.1%, and the final shape of the steel pipe is: the outer diameter is 32.0mm, and the wall thickness is 3.20mm.

Embodiment 3

[0094] Although steel pipes were produced in the same manner as in Example 1, the shape of the blank pipe was 50.8 mm in outer diameter and 4.0 mm in thickness. After heat-treating the blank tube by the same quenching and tempering as in Example 1, as shown in Table 2, cold drawing was performed once with a reduction in area of 40.7%, and then performed in the same manner as in Example 1. stress relief annealing. The final shape of the steel pipe is: outer diameter 40.0mm, wall thickness 3.00mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com