Cosine gear transmission mechanism

A technology of cosine gears and transmission mechanisms, which is applied in the direction of gear transmissions, transmissions, belts/chains/gears, etc. It can solve the problems of restricting the development of the gear industry, low contact strength of gear teeth, and small value of the main curvature radius. Small, large pressure angle, small relative sliding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

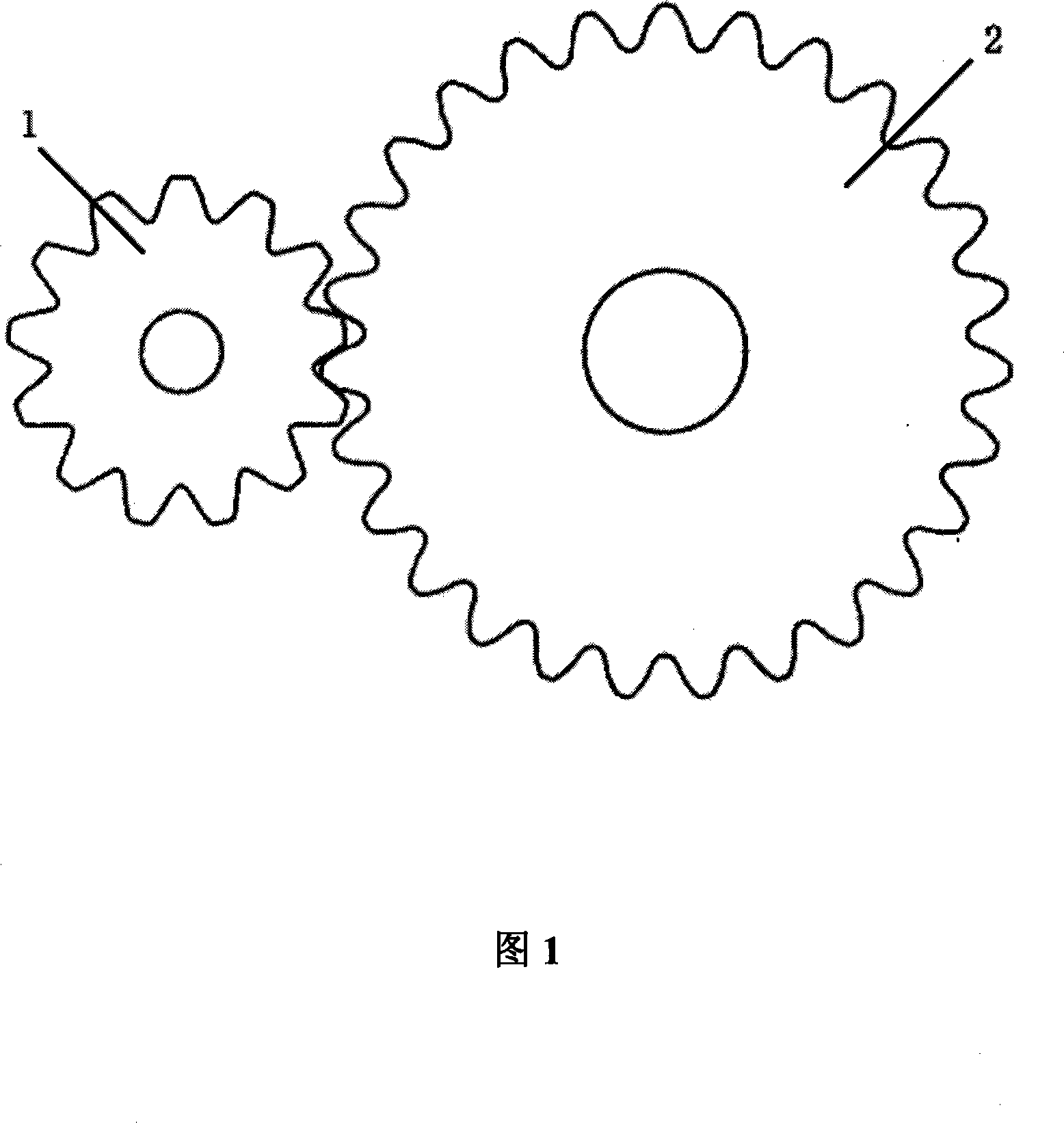

[0010] Referring to Fig. 1, the cosine gear transmission mechanism includes a cosine gear 1 and a gear 2 conjugated thereto, the tooth profile curve of the cosine gear 1 is a cosine curve, and the tooth profile curve of the conjugate gear 2 is amplitude and period The conjugate curve of the cosine gear that changes with the transmission ratio, the meshing line of the two gears is approximately a straight line.

[0011] The tooth profile curve and meshing line of the cosine gear 1 and its conjugate gear 2 are determined in the following manner:

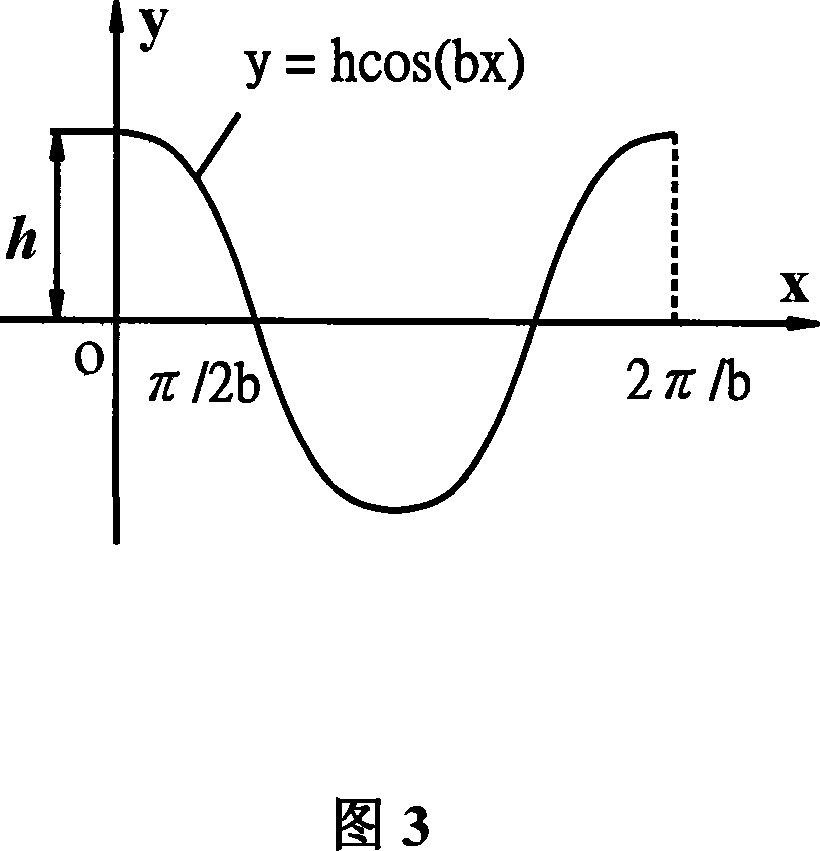

[0012] The first step is to determine the parameter equation of the tooth profile curve of cosine gear 1. Referring to Figure 2 and Figure 3, the zero line of the cosine curve is used as the pitch line of the gear, one cycle of the curve is used as a tooth pitch of the gear, and the amplitude h of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com