Method for preparing water softening aluminium stone of sodium aluminate solution carbonation resolving

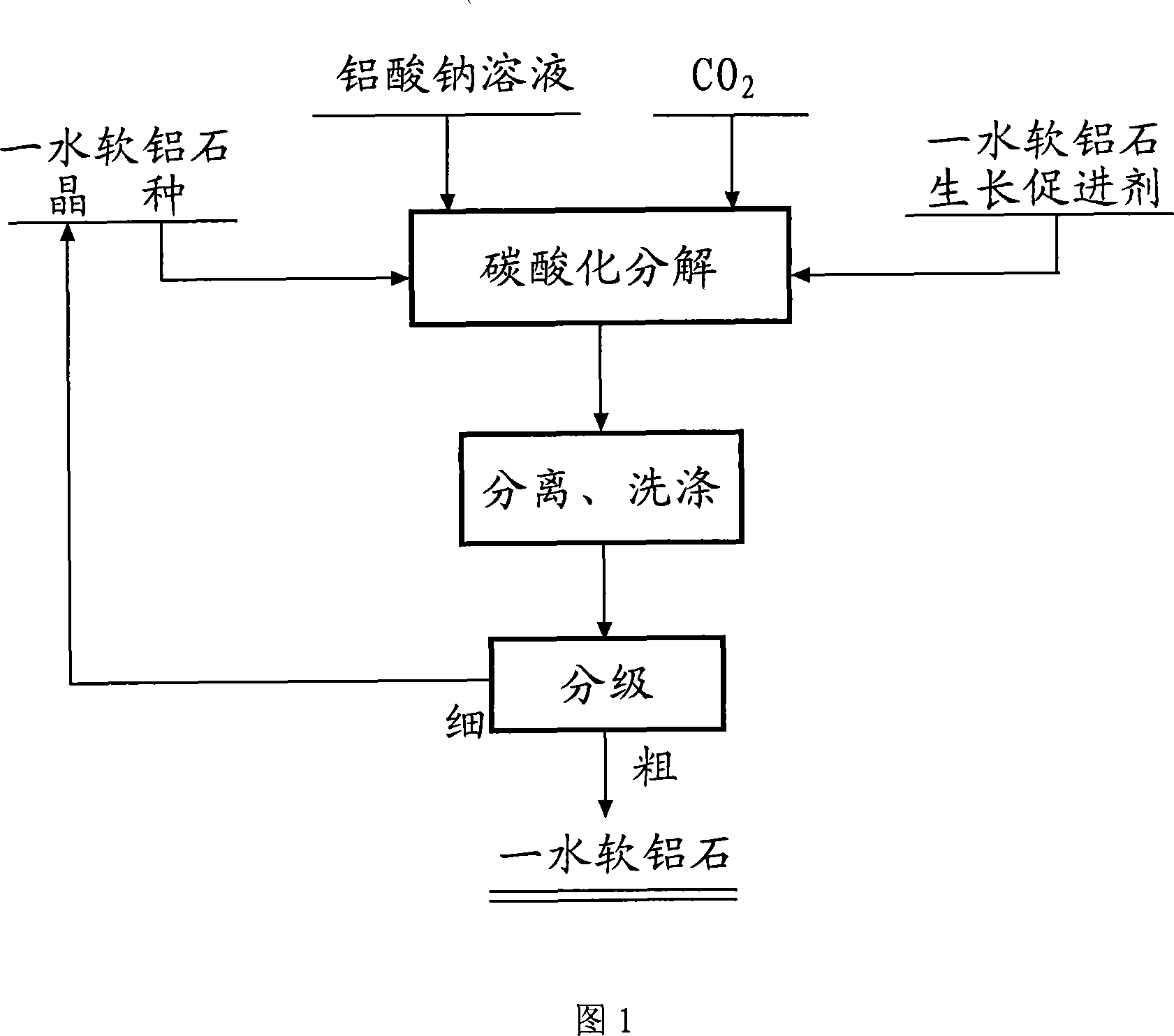

A technology of carbonation decomposition and boehmite, which is applied in the field of industrial production of boehmite and metallurgical grade alumina by carbonation decomposition of sodium aluminate solution, can solve the problems of high raw material cost and complicated process flow, etc. Achieve the effect of large-scale industrialization with broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

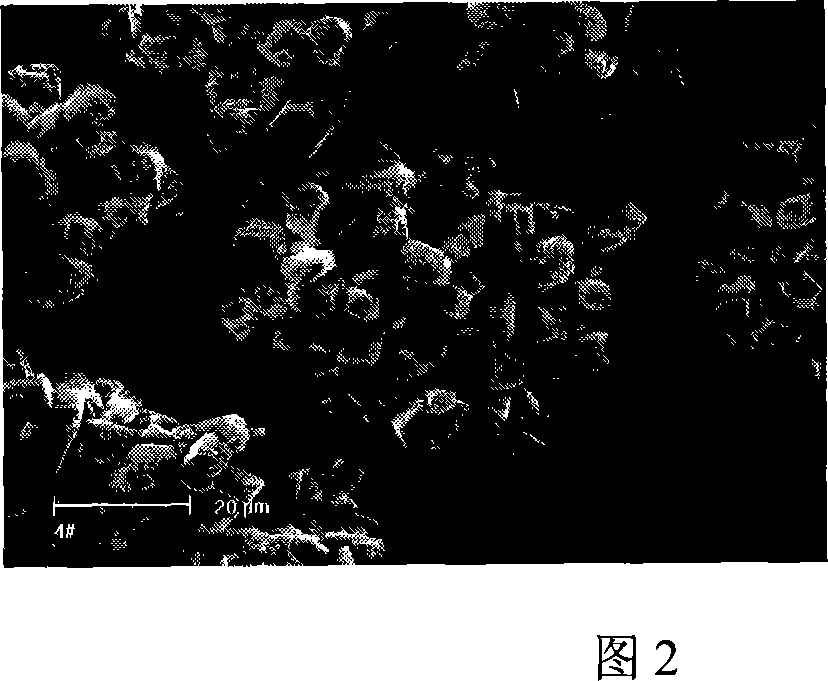

Embodiment 1

[0038] Prepare sodium aluminate solution with industrial aluminum hydroxide and sodium hydroxide, the chemical composition is Al 2 o 3 100 g / L, the causticization factor is 1.45. Carbon dioxide is introduced into the decomposition process, the gas concentration is 40%, and the decomposition process CO 2 The ventilation rate is 20 liters / liter solution·hour. When gibbsite is used as the seed crystal, the seed crystal coefficient is 1.0, and the decomposition time is 4h. See Figure 2(c)-(d) for the morphology of seed crystals and products. SEM analysis shows that boehmite is mainly composed of agglomerates of rhombohedral grains, while gibbsite is mainly composed of hexagonal grains. This example illustrates that by adding boehmite seed crystals, directional crystallization of boehmite can be achieved through carbonation and decomposition, thereby preparing a boehmite product.

Embodiment 2

[0040] Experimental industrial sodium aluminate solution, the chemical composition is Al 2 o 3 105 g / l with a causticization factor of 1.50. Carbon dioxide is introduced into the decomposition process, the gas concentration is 35%, CO 2 The ventilation rate is adjusted between 20-30 liters / liter solution·hour. Boehmite is used as the seed crystal, the seed crystal coefficient is 0.5, the decomposition time is 4.5h, 200ppm stearic acid is added during the decomposition process, and phase analysis shows that 98% of the product is composed of boehmite.

Embodiment 3

[0042] Prepare sodium aluminate solution with industrial aluminum hydroxide and sodium hydroxide, the chemical composition is Al 2 o 3 100 g / L, the causticization coefficient is 1.45, carbon dioxide is introduced into the decomposition process, the gas concentration is 40%, CO 2 The ventilation rate is adjusted at 20-40 liters / liter solution·hour. Boehmite was used as the seed crystal, the seed crystal coefficient was 1.5, and the decomposition time was 3 hours. During the decomposition process, 150 ppm of a mixture of stearic acid and stearyl alcohol was added. Phase analysis showed that 99% of the product was composed of boehmite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com