Stator embedded electromagnetic suspension microsystem

An electromagnetic levitation and stator internal technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of lack of high-precision micro-gyroscopes, poor anti-interference performance of stable suspensions, and poor lateral stiffness adjustability of suspensions, etc. problem, achieve the effect of overcoming friction and wear, increasing suspension stiffness and lateral stability stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

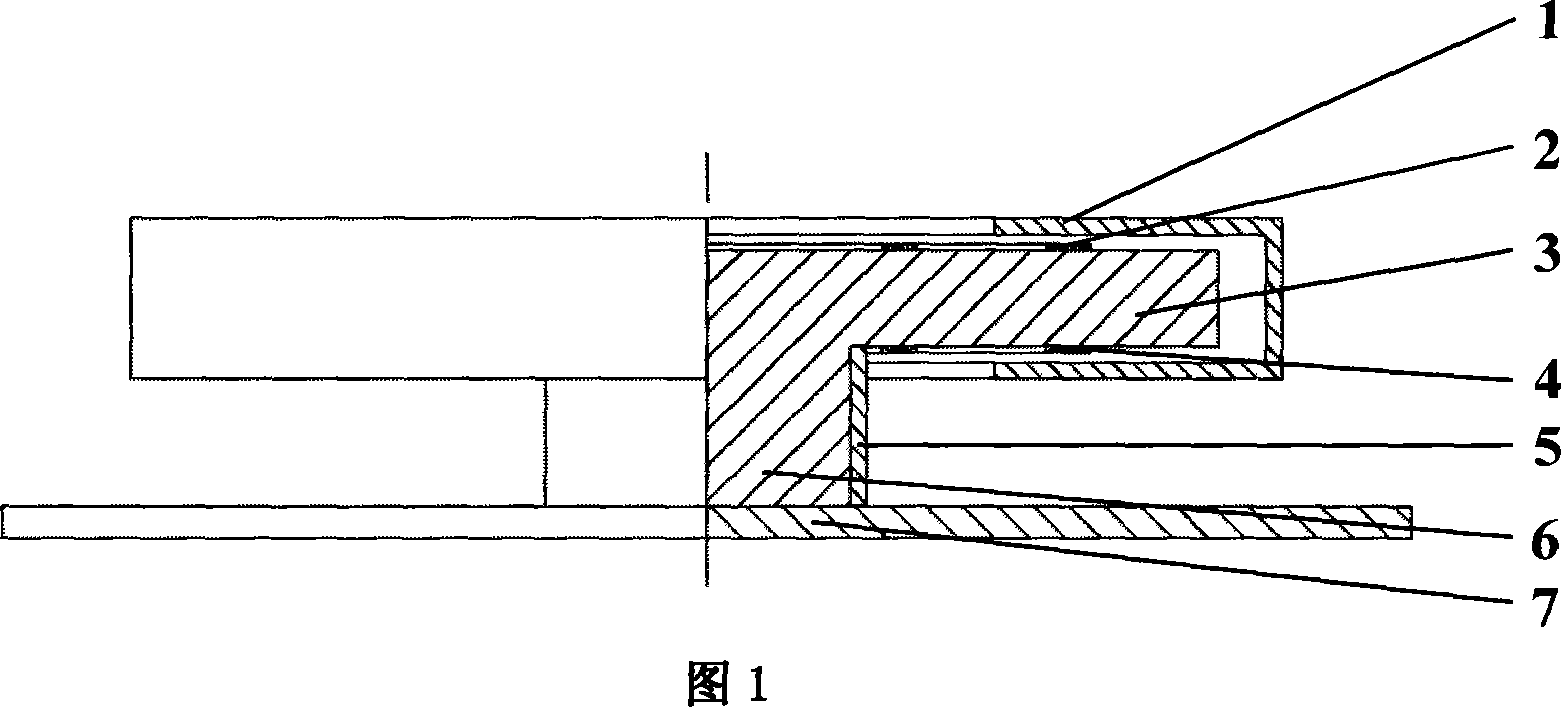

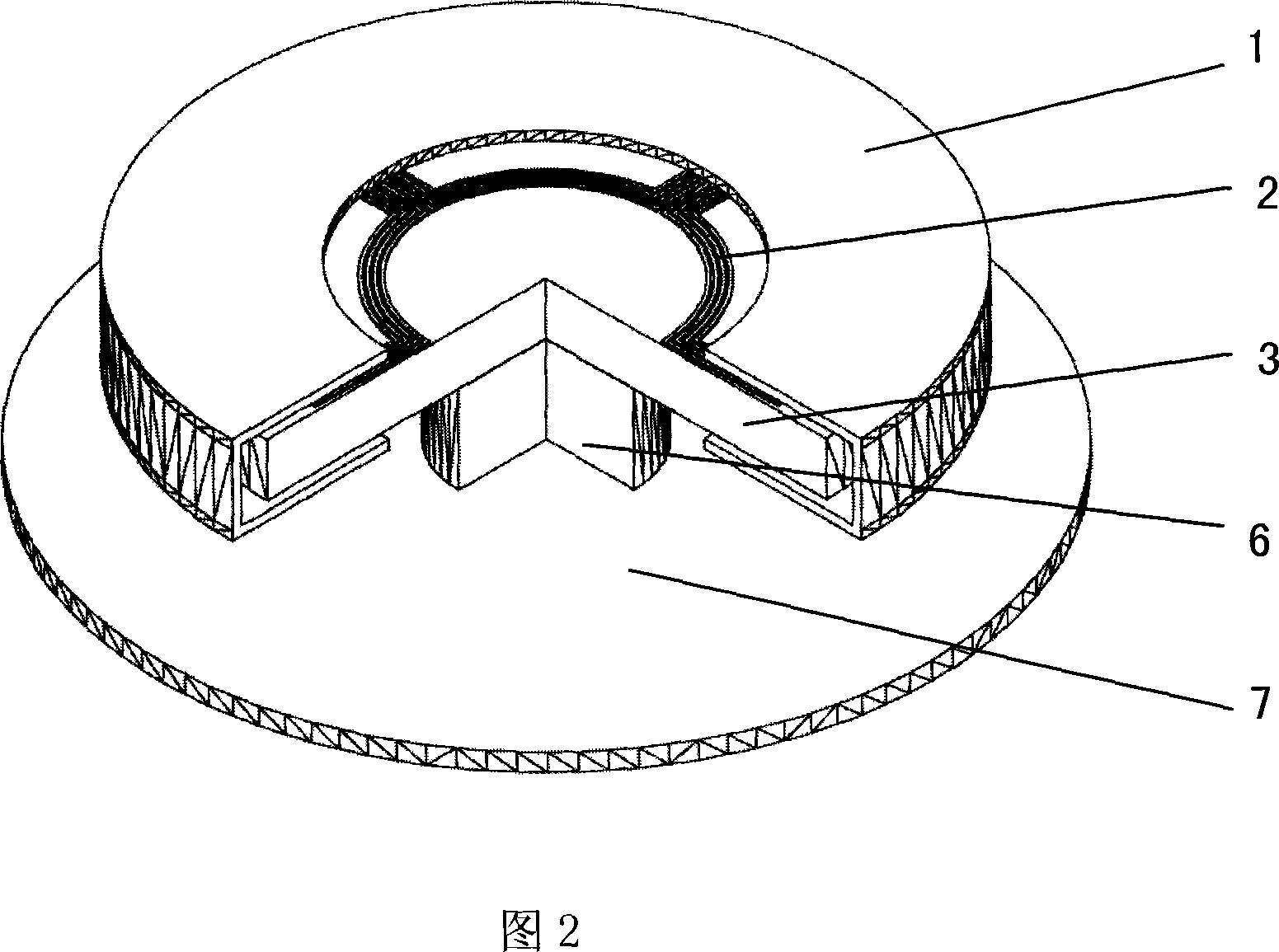

[0015] As shown in FIG. 1 and FIG. 2 , this embodiment includes: a circular box-shaped micro-suspension mass 1 , an upper stator 2 , an intermediate base 3 , a lower stator 4 , leads 5 , an intermediate column 6 , and a lower base 7 .

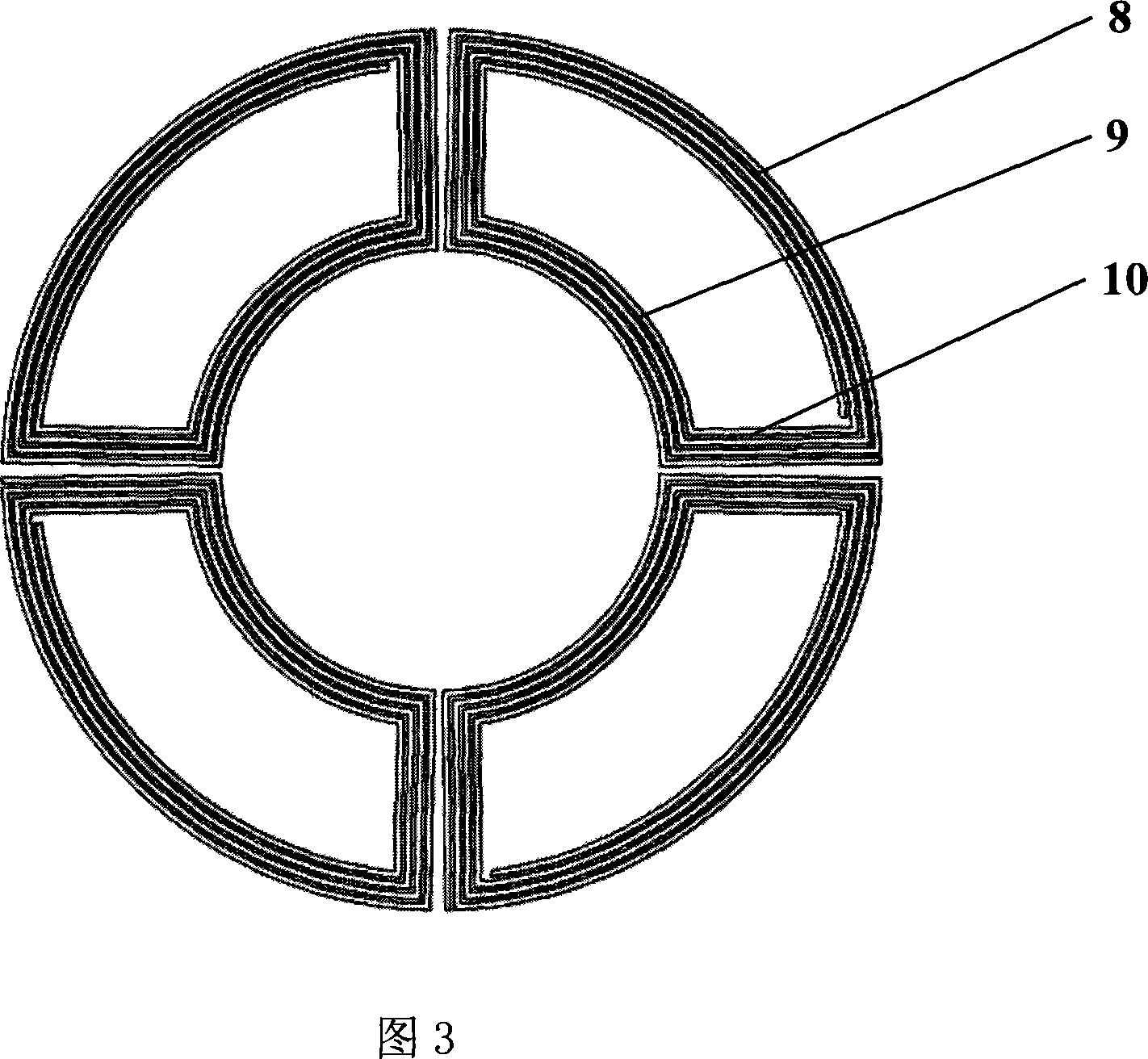

[0016] As shown in FIG. 3 , the upper stator 2 and the lower stator 4 are identical, and consist of three parts: the outer ring 8 of the stable suspension coil, the inner ring 9 of the stable suspension coil, and the connecting wire 10 . The connection relationship is: the upper stator 2 and the lower stator 4 are both arranged on the intermediate b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com