Integrated waste water treating machine

A technology for comprehensive wastewater and wastewater treatment, applied in biological water/sewage treatment, adsorption water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of large limitations in wastewater composition and difficult comprehensive wastewater treatment discharge water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

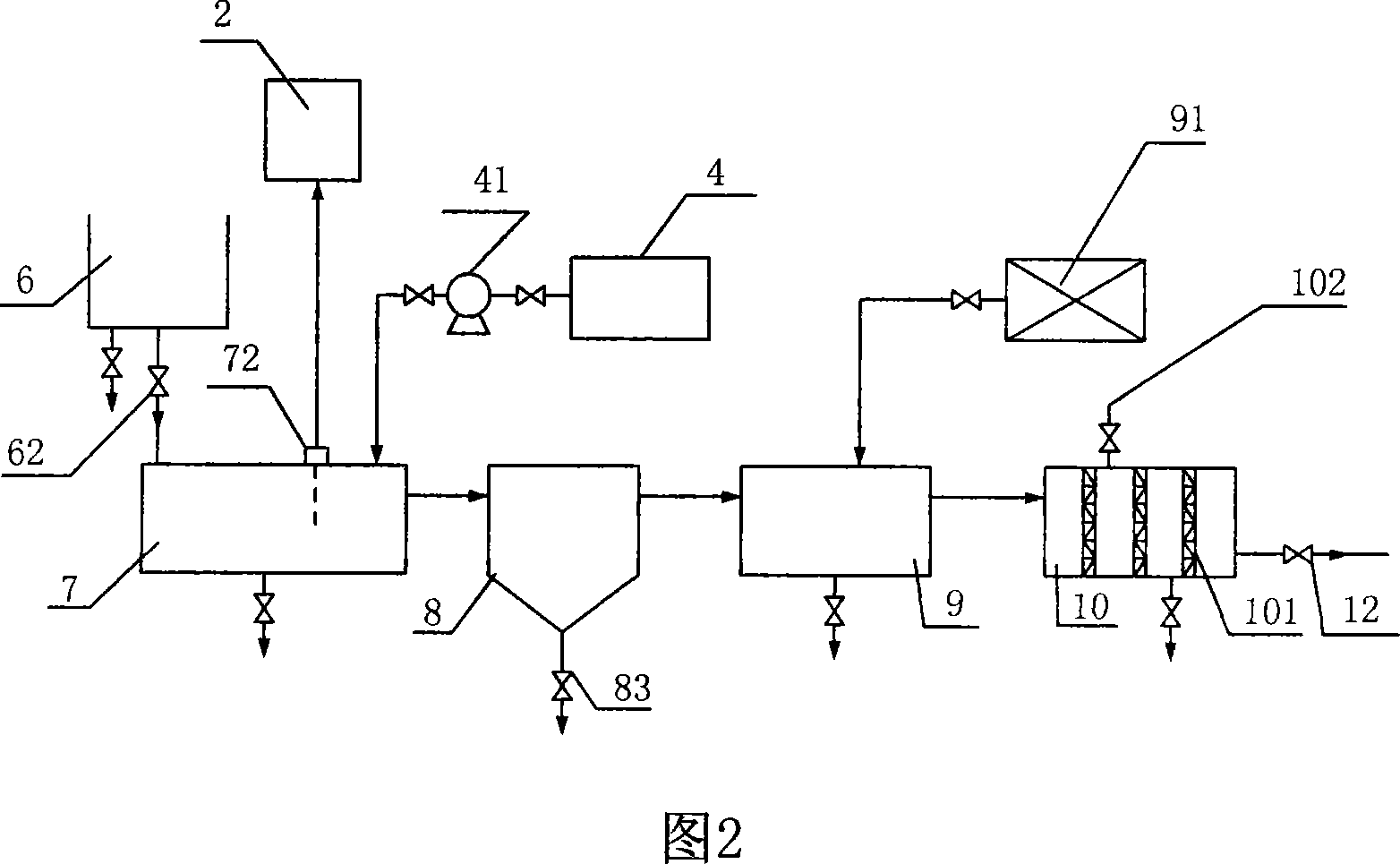

[0059] As shown in Figures 1 and 2, a comprehensive wastewater treatment machine includes a console 1, a central processing unit 2, an electric control box 3, a medicine box 4, an ozone generator 91, a regulating pool 6, and a wastewater treatment pool; the wastewater treatment pool It consists of a comprehensive reaction pool 7, a sedimentation pool 8, an oxidation pool 9, and an activated carbon biofilter 10 connected sequentially from the side where the waste water is introduced. Regulating tank 6 is arranged on the side top of comprehensive reaction tank 7, and there is a drop between regulating tank 6 and comprehensive reaction tank 7, and regulating tank 6 is set as an open pool, and its bottom is provided with pipeline directly connected with comprehensive reaction tank 7, and in this pipeline A regulating valve 62 is set on the top; a pH meter 72 is set in the comprehensive reaction tank 7; the medicine box 4 is arranged above the comprehensive reaction pool 7, so that ...

Embodiment 2

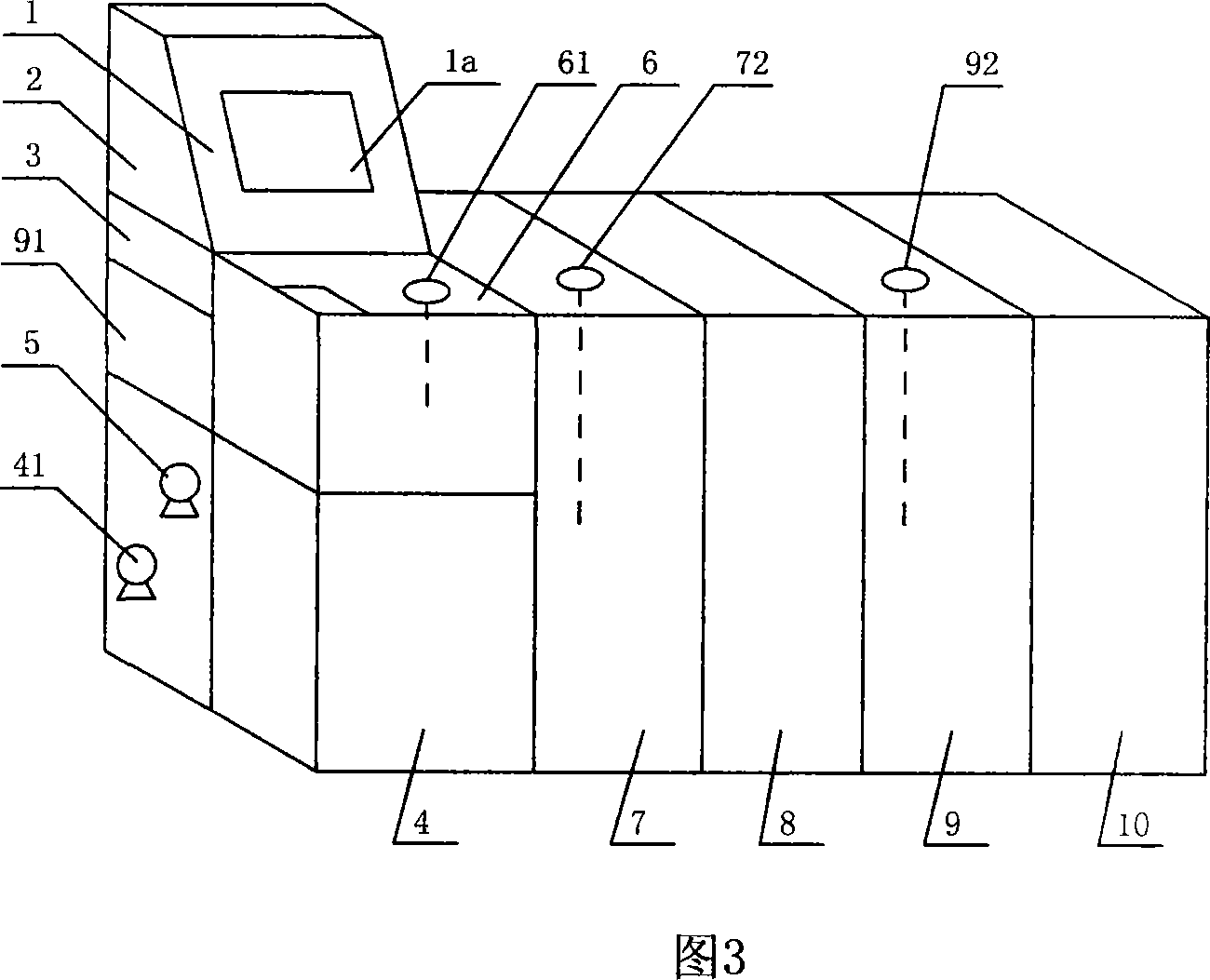

[0064] As shown in Figures 3 and 4, the difference from Embodiment 1 is:

[0065] Adjusting pool 6 is arranged on the top of medicine box 4, medicine pump 41 is set on the liquid discharge main pipe of medicine box 4 leading to comprehensive reaction pool 7, first water delivery pump 5 and medicine pump 41 are set on the pipeline of regulating pool 6 leading to comprehensive reaction pool 7 The first water delivery pump 5 is electrically connected with the central processing unit 2, and they are placed under the electric control box 3. The regulating pool 6 is a closed pool, and the upper part of the pool is provided with a water inlet. A first water level gauge 61 is set in the regulating tank 6, and the first water level gauge 61 is electrically connected to the central processing unit 2; an ORP meter 92, that is, an oxidation-reduction potential meter, is set in the oxidation tank 9, and the ORP meter 92 is connected to the central processing unit. 2 electrical connections...

Embodiment 3

[0069] As shown in Figures 5 and 7, the difference from Embodiment 2 is:

[0070] As shown in Figure 5, the outlet of the chemical box 4 is respectively provided with a drug discharge valve and a connected drain main pipe, and the liquid discharge main pipe leads into the comprehensive reaction pool 7; the chemical box 4 is divided into four parts, respectively storing acidic chemicals, NaOH, PAM, PAC; liquid level gauges 42, 43, 44, 45 are respectively arranged in the box body of the four parts of the medicine box 4, and are electrically connected with the central processing unit 2; the bottoms of the four parts of the medicine box 4 are all provided with medicine discharge The valve is also communicated with the drain main pipe of the medicament box 4. A medicine pump 41 is arranged on the liquid discharge main pipe of the medicine box 4 ; the medicine discharge valve and the medicine pump 41 are electrically connected with the central processing unit 2 , and the central pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com