Automatic stabilized precision control device of the tundish in the center of the concasting

A continuous casting tundish, automatic stabilization technology, applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem of poor stability of tundish liquid level, unstable casting quality, tundish weight change, etc. problems, to achieve the effect of reducing liquid level fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

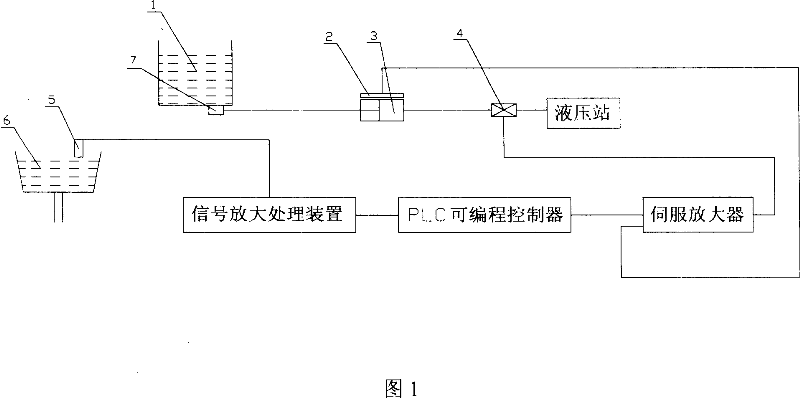

[0010] As shown in Figure 1, the continuous casting tundish liquid level automatic stable and precise control device consists of a non-contact liquid level detector 5, a signal amplification processing device, a PLC programmable controller, a servo amplifier, a servo valve 4, a hydraulic cylinder 3, The slide plate is composed of 7 hydraulic stations, and the non-contact liquid level detector is set on the upper part of the tundish 6 liquid steel, which is connected with the signal amplification processing device, and the detected tundish liquid level signal is transmitted to the control cabinet, and then through the PLC The programmable controller converts the tundish liquid level signal into a liquid level control signal, and the liquid level control signal is transmitted to the servo valve through the servo amplifier. The servo valve 4 is connected to the hydraulic cylinder 3. The power of the hydraulic cylinder comes from the hydraulic station, and the hydraulic cylinder con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com