Light irradiation apparatus, light irradiation method, crystallization apparatus, crystallization method, and semiconductor device

A light irradiation device and light irradiation technology, applied in semiconductor/solid-state device manufacturing, crystal growth, optical components, etc., can solve problems such as inconvenience, inability to generate crystal grains, and inability to generate light intensity distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

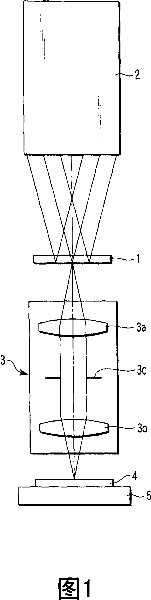

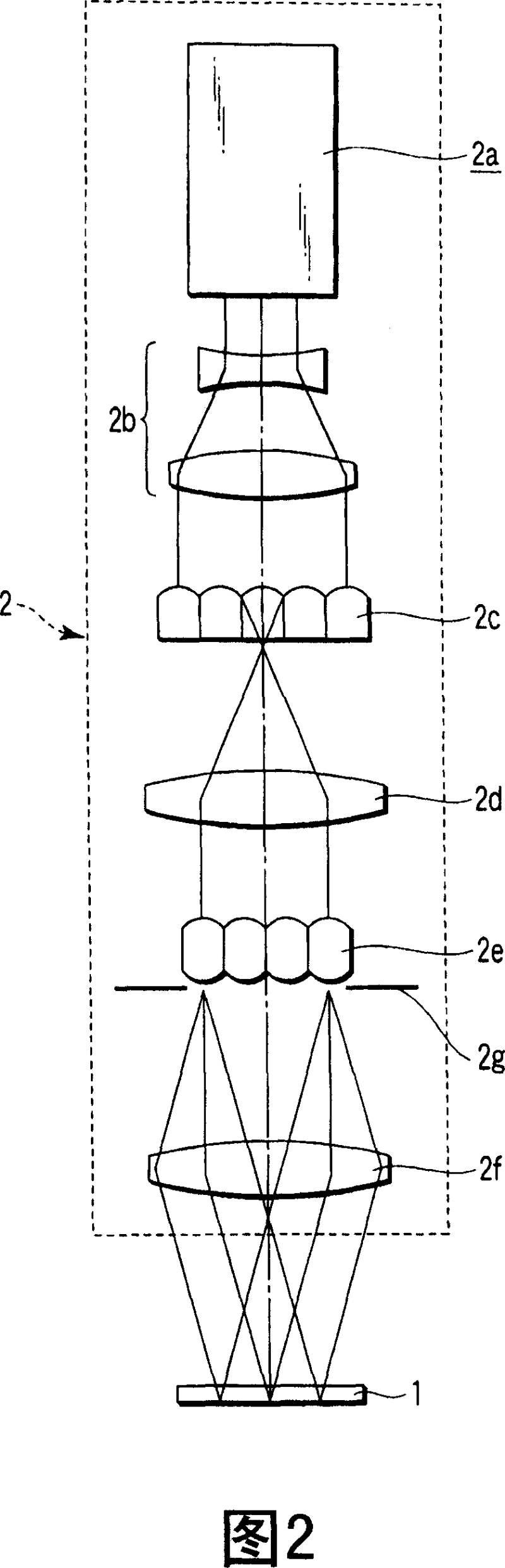

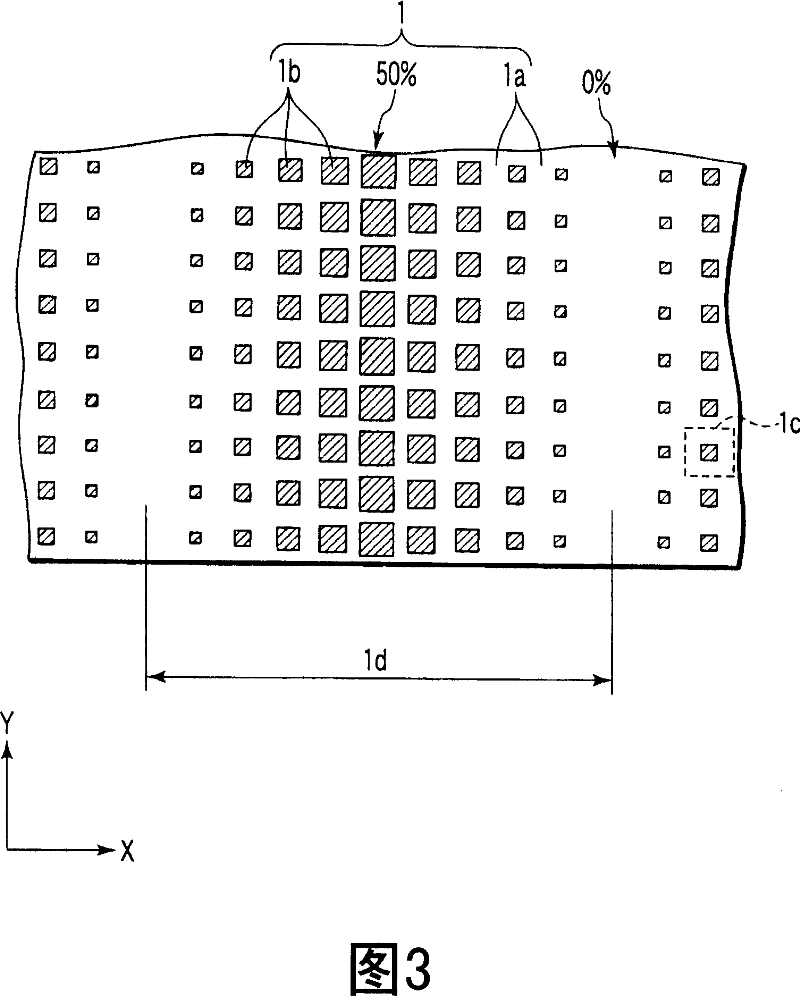

[0055] Embodiments according to the present invention are explained below with reference to the drawings. FIG. 1 is a schematic diagram illustrating a crystallization apparatus according to an embodiment of the present invention. FIG. 2 is a view schematically showing the internal structure of the lighting system of FIG. 1 . 1 and 2, the crystallization apparatus according to the present embodiment includes a light modulation element 1 such as a phase shifter, which modulates the phase of incident light (beam) to form light (beam) with a predetermined light intensity distribution, the illumination light modulation An illumination system 2 of the element 1, an image forming optical system 3, and a substrate pole 5 holding a processing target substrate 4 having a semiconductor film such as non-single crystal silicon.

[0056] The structure and function of the light modulation element 1 are explained later. The illumination system 2 includes a XeCl excimer laser (beam) source 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com