Method and device for detecting coal powder performance

A technology of pulverized coal combustion and detection method, which is applied in the direction of fuel oil testing, chemical analysis by combustion, material inspection products, etc. It can solve the problems of high power consumption, time-consuming and laborious, complicated operation, etc., and achieve shortened measurement time and less human factors , The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. According to the provisions of GB474-1996 "Preparation Method of Coal Samples", the analytical coal samples below 0.2mm are prepared and air-dried.

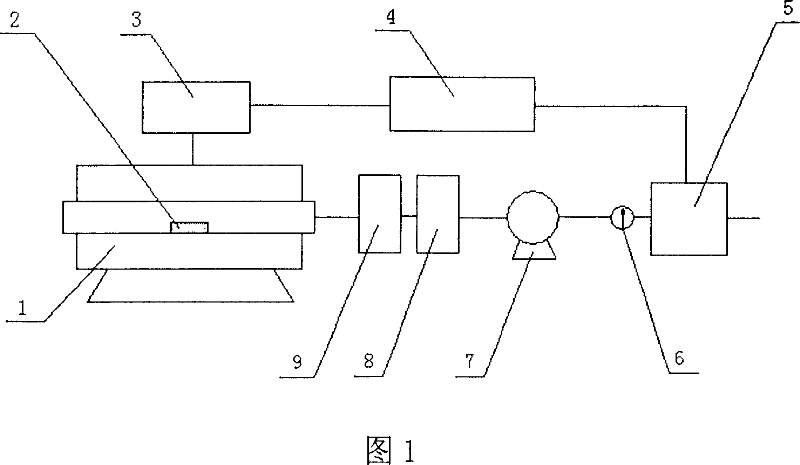

[0023] 2. Start the infrared gas analyzer 5 and the suction pump 7, and adjust the rotameter 6 to meet the measurement flow required by the infrared gas analyzer.

[0024] 3. Weigh 100±2mg (accurate to 0.1mg) of an air-dried coal sample with a particle size of 0.2mm or less, put it into an ash dish, vibrate lightly to spread the coal sample evenly, and then send it into a combustion chamber with a temperature not exceeding 100°C. 2 in the constant temperature zone of the furnace.

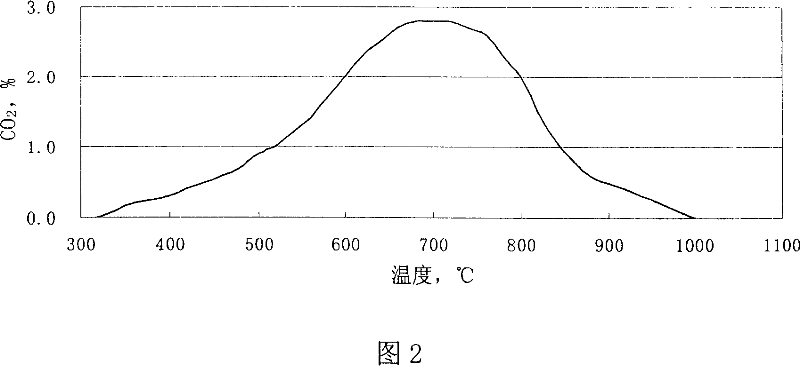

[0025] 4. After the preheating of the infrared gas analyzer is completed and the test conditions are met, the temperature controller 3 is started to rapidly raise the temperature of the combustion furnace 1 under the condition of a constant heating rate. Simultaneous tracking and detection of CO 2 gas content.

[0026] 5. Use the computer ...

Embodiment 2

[0029] 1. According to the provisions of GB474-1996 "Preparation Method of Coal Samples", the analytical coal samples below 0.2mm are prepared and air-dried.

[0030] 2. Start the temperature controller 3 to heat the combustion furnace 1, start the infrared gas analyzer 5 and the air pump 7, and adjust the rotameter 6 to meet the measurement flow required by the infrared gas analyzer. After the combustion furnace 1 is heated to 1200°C, it will continue to maintain a constant temperature.

[0031] 3. Weigh 100±2mg (accurate to 0.1mg) of an air-dried coal sample with a particle size of 0.2mm or less and put it into the ash dish, and shake it lightly to spread the coal sample evenly.

[0032] 4. After the preheating of the infrared gas analyzer 5 is completed and the constant temperature time of the combustion furnace is > 15 minutes, quickly send the ash dish containing the coal sample into the constant temperature zone of the combustion furnace 2 .

[0033] 5. Use the computer ...

Embodiment 3、4

[0036] According to the same steps as in Example 2, the combustion performance of a certain coal powder at a constant temperature of 800°C and a constant temperature of 1000°C was measured respectively, and the results are shown in FIG. 4 .

[0037] By using the pulverized coal combustibility detection method and the device thereof of the present invention, the combustibility index of pulverized coal can be measured conveniently, quickly and accurately, and quantified. Based on this, the type of coal injection and its combination can be reasonably selected to achieve complementary coal quality, improve its combustion performance, meet the requirements of blast furnace injection, and achieve the best economic effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com