Method for preparing nuclease P1 by ferment process

A nuclease and fermentation technology, applied in the biological field, can solve the problems of high production cost, long fermentation cycle, and low enzyme activity unit, and achieve the effect of reducing equipment cost and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

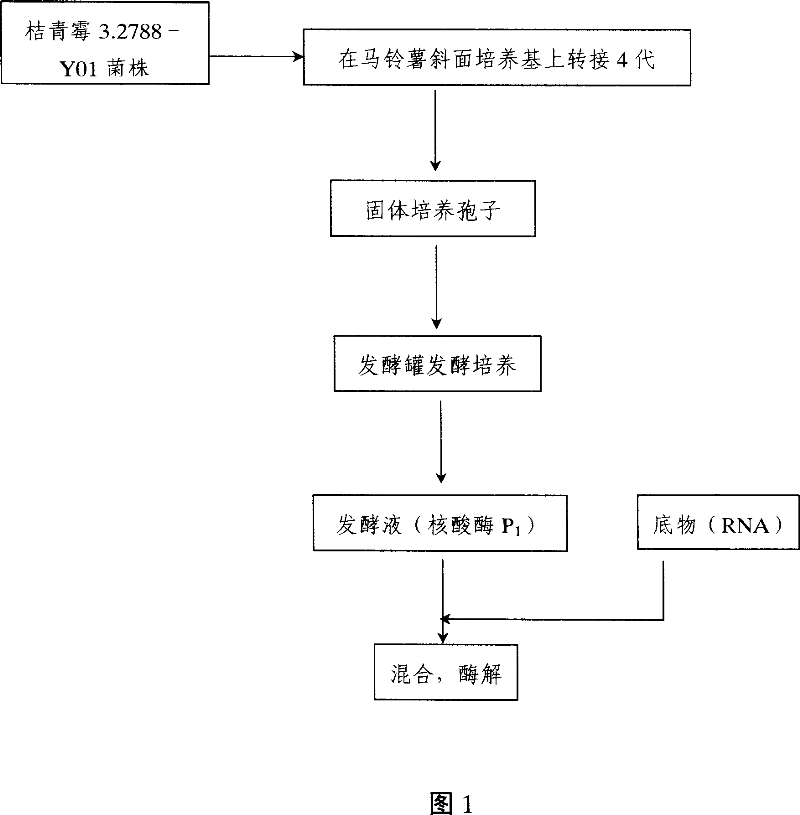

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 prepares bran spores

[0042] 1. Activation of strains

[0043] Take 1 ring of bacteria and insert it into the potato slant medium, culture it at 28-30°C for 3 days as the first generation, and so on, transfer it to the fourth generation slant medium, and store it routinely for later use.

[0044] 2. Expand training

[0045] Fully wash the fresh fourth-generation slant with sterile water to obtain a spore suspension, take 0.1-2.0 ml and insert it into the prepared bran medium, and cultivate it at 28-30° C. for 3 days. Bran spore count reaches 10 9 pcs / g.

Embodiment 2

[0046] Embodiment 2 (2 tons of fermentation tanks)

[0047]1. Medium formula: phosphate 15Kg, magnesium sulfate 3Kg, calcium carbonate 3Kg, zinc sulfate 1.2Kg, industrial peptone 15Kg, industrial glucose 9Kg, make up to 1500L with water.

[0048] 2, inoculum size: 900 grams of bran spores (embodiment 1);

[0049] 3. Cultivation temperature: 29~30℃;

[0050] 4. Cultivation speed: 150rpm~250rpm, when the dissolved oxygen drops below 40%, adjust the speed;

[0051] 7. Ventilation volume: 1.5m 3 / min;

[0052] 8. Tank pressure: 0.05~0.06Mpa;

[0053] 9. Initial pH value: 6.0

[0054] 10. Supplementary culture medium:

[0055] The fermentation culture is about 24.1 hours, and the dry material required for the 250L fermenter culture medium is added to the medium for the first time;

[0056] Fermentation culture is about 29.5 hours, and the medium is supplemented with the dry material required for the 250L fermenter medium for the second time;

[0057] The fermentation cultur...

Embodiment 3

[0067] Embodiment 3 (2 tons of fermentation tanks)

[0068] 1. Medium formula: phosphate 3Kg, magnesium sulfate 1.3Kg, calcium carbonate 1.3Kg, zinc sulfate 1.5Kg, industrial peptone 30Kg, industrial glucose 6Kg, make up to 1500L with water.

[0069] 2. Inoculation amount: 840 grams of bran spores;

[0070] 3. Cultivation temperature: 29~30℃;

[0071] 4. Cultivation speed: 150rpm~270rpm, when the dissolved oxygen drops below 40%, adjust the speed;

[0072] 7. Ventilation volume: 1.5m 3 / min;

[0073] 8. Tank pressure: 0.05~0.06Mpa;

[0074] 9. Initial pH value: 5.9

[0075] 10. Supplementary culture medium:

[0076] Ferment and cultivate for about 23 hours, start the medium and add the dry material required for the 250L fermenter medium for the first time;

[0077] Fermentation and cultivation for about 28 hours, the second supplement of the medium with the dry material required for the medium of the 250L fermenter;

[0078] Ferment and cultivate for about 33 hours, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com