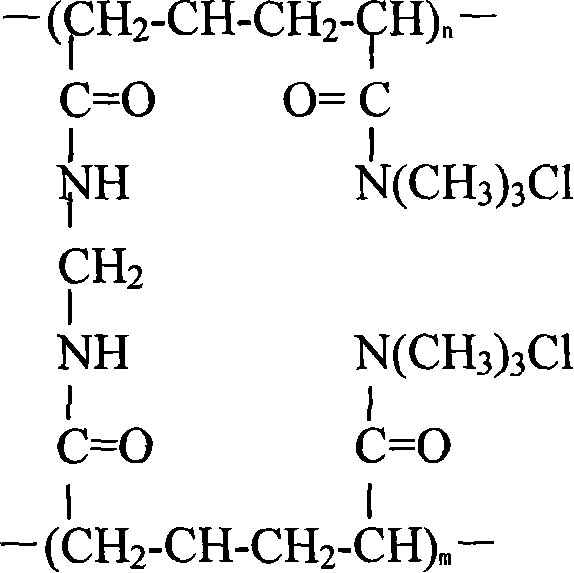

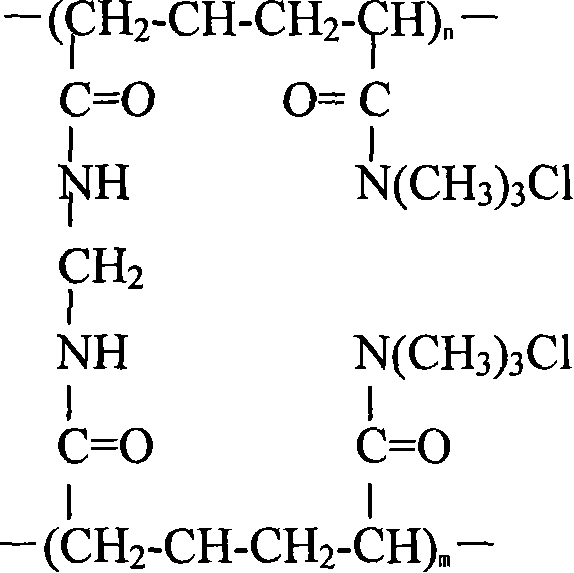

Cation polypropylene amides gel micro-ball and preparation method thereof

A polyacrylamide gel, gel microsphere technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problem that anionic polymers cannot be reused, the solid particle size is large, and the oil layer migration ability is poor. and other problems, to achieve the effects of good migration capacity, improved sweep coefficient, and strong sweep volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0011] Example: Take 120 parts of acrylamide monomer, 25 parts of methacryloxyethyltrimethylammonium chloride, 3 parts of N, N-methylenebisacrylamide, 6 parts of ammonium persulfate, 1000 parts of water, The above materials are calculated in parts by weight, mixed with each other and fully dissolved to form an aqueous solution, which is loaded into a spray tank with a spray particle diameter of 10-20 microns. Put 1,000ml of peanut oil into a 2,000ml beaker and heat it to 100°C, spray the prepared raw material solution into the oil with a nozzle with a pore size of 10-20 microns, and the atomized droplets are suspended in the oil. Polymerization reaction, after the spraying is completed, the polymerization reaction is completed, and the cationic polyacrylamide gel microspheres with a diameter of 10-20 microns can be obtained after precipitation. The molecular weight of the polyacrylamide gel is about 11 million. Under a 1000X optical microscope, it can be seen that the synthesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com