Self-burning simple harmless life refuse high temperature combustion furnace

A high-temperature combustion technology for domestic waste, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems that threaten human living environment and health, environmental pollution, etc., and achieve easy, timely and nearby harmless disposal, reduce costs Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

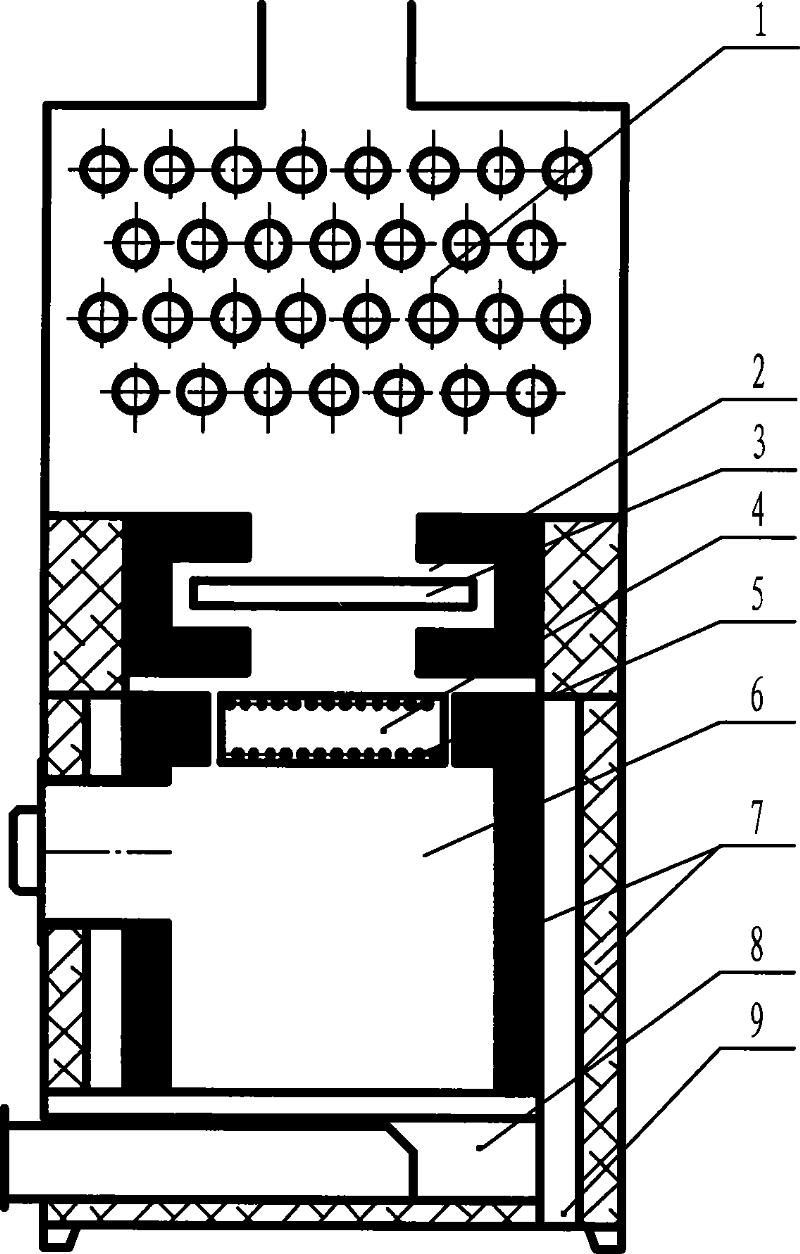

[0008] Household waste is put into the furnace (6), and burns in the furnace through the furnace ash chamber (8) into the air. When the flue gas enters the secondary air intake combustion zone (4), due to the limitation of the flow channel, the flue gas passes through the vicinity of the high-temperature air delivery hole (5), so that the flue gas is initially mixed with the preheated high-temperature air, At the same time, part of the combustible components and soot particles in the flue gas have started to burn. The flame formed by the flue gas and the high-temperature air injected into it enters the high-temperature mixed-air combustion zone (2) after coming out of the secondary air-inlet combustion zone (4), and first gathers in the hole in the middle below the high-temperature mixed-air combustion zone (2), and then Add a refractory disk (3) above the hole to stop the fire, so that the fire will spread around after bypassing the hole. This process will cause the flames to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com