Production of miglitol

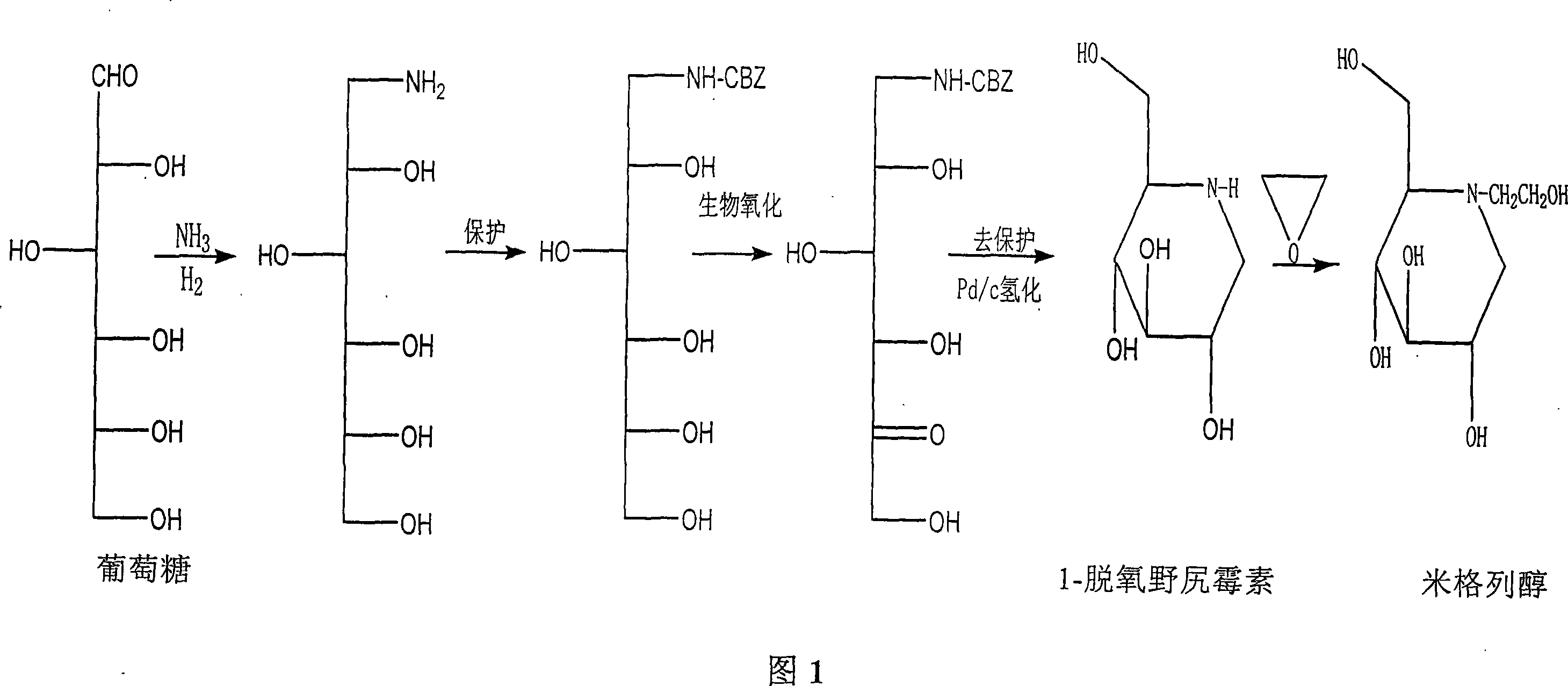

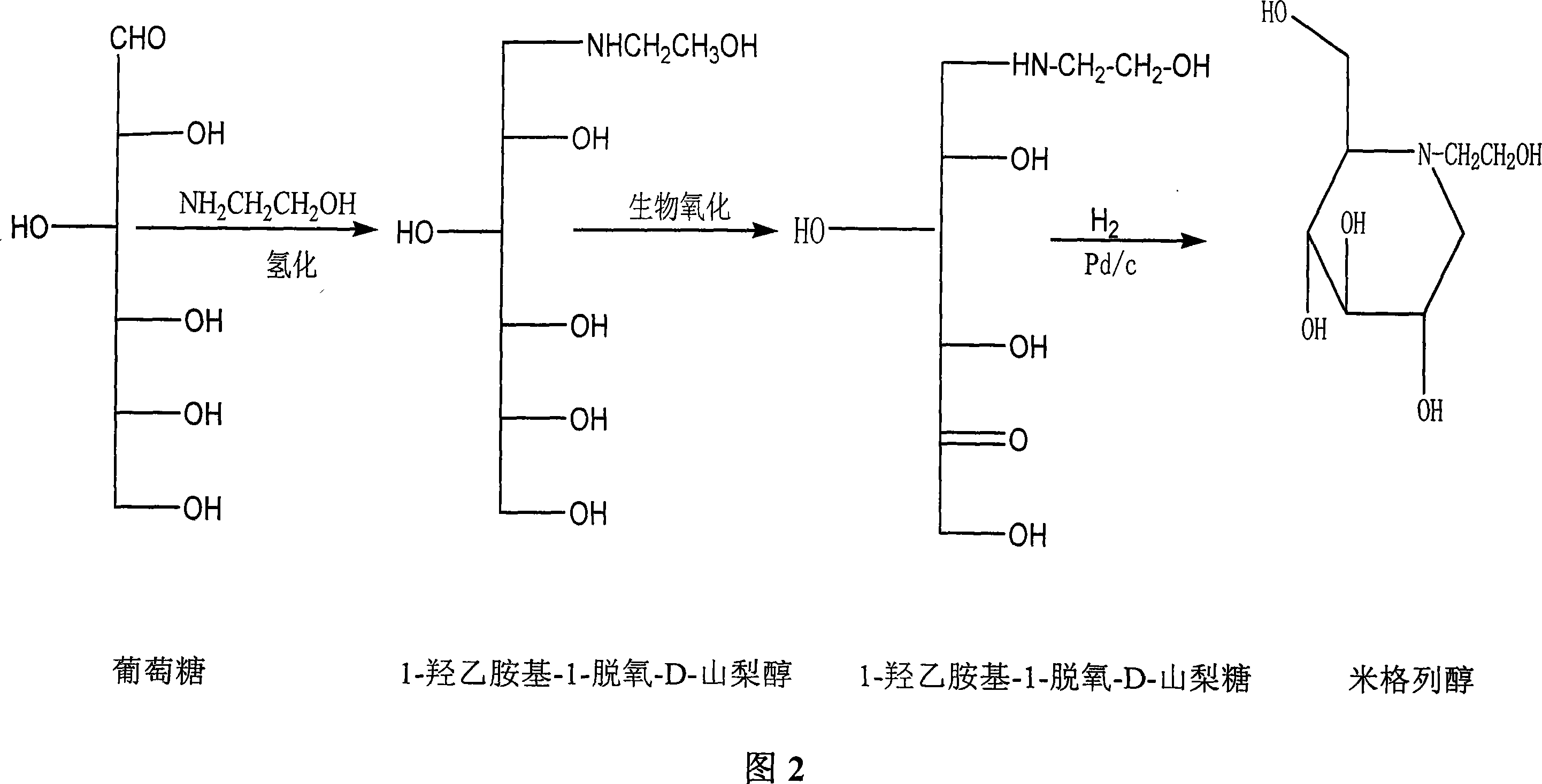

A production method and a sorbitol technology are applied in the production field of miglitol, which can solve the problems such as labor-intensive, time-consuming, poor safety of catalysts, and achieve the effects of time-saving operation, improved safety and favorable industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of gluconic acid oxidizing bacteria cells

[0033] Strain: Gluconic acid oxidizing bacteria DSM 2003

[0034] Medium: Alcohol extract powder 2.5% (W / V), sorbitol 7.2%, dipotassium hydrogen phosphate 0.2%, ammonium sulfate 0.5%, magnesium sulfate 0.05%, trace element QS

[0035] Inoculation amount: 10% (V / V)

[0036] Culture conditions: 28-30°C, oxygen flow rate 1:1 (V / V), pH 5.0-6.0 and culture for 22-24 hours.

[0037] The tank condition is OD=1.7~1.9, no bacteria.

[0038] In a high-speed centrifuge, isolate the bacteria. The bacterial cell yield (wet weight) is about 1-1.2% of the fermentation broth.

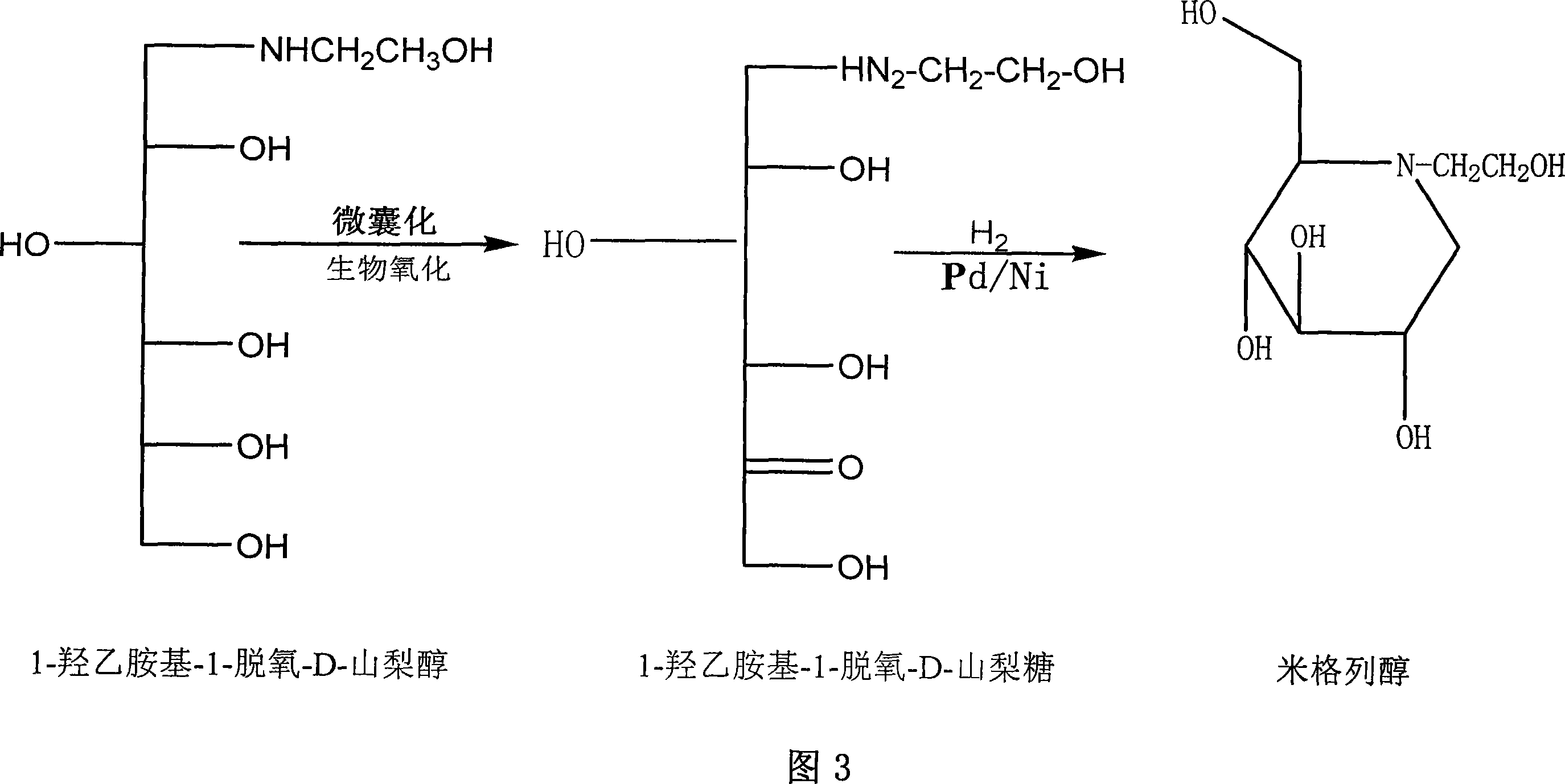

[0039] Preparation of microcapsule-coated gluconic acid oxidizing bacteria

[0040] Take 100g of wet bacteria, add it to 100ml of 3% sodium alginate solution, stir the suspension, and add 10% Cacl dropwise through a polytetrafluoroethylene capillary 2 In 500ml of the solution, the frequency and intensity of capillary vibration are controlled, and the ...

Embodiment 2

[0046] Preparation of Microencapsulated Gluconic Acid Oxidizing Bacteria

[0047] Take 50g of the wet bacterium of gluconic acid oxidizing bacteria, add 2% sodium alginate and 4% glycerin into 50ml of the combined solution, stir evenly, pass the suspension through a polytetrafluoroethylene capillary dropping device, and add 4% Chitosan solution 250ml. Simultaneously stir to ventilate. Microcapsules with a diameter of about 2 mm were collected, washed with 0.9% NaCl, and set aside.

[0048] In a 10-liter automatic fermentation tank, add 2.5L of 3.5% 1-hydroxyethylamino-1-deoxy-D-sorbitol and 500g of bacteria-containing microcapsules, stir at 30-31°C, 100-150rpm, and maintain pH5 .0~6.0 under the condition of 3L / min of air, transform for 23~28hr, filter out bacterial cell microcapsules, add diatomaceous earth and activated carbon to the filtrate, stir for 30 minutes, filter, add 5% nickel-palladium catalyst 30g in the filtrate 35-40°C, hydrogenation at 2-5MpA for 5-7 hours, s...

Embodiment 3

[0052] Preparation of microencapsulated gluconic acid oxidizing bacteria

[0053] Take 100 g of gluconic acid oxidizing bacteria and wet bacteria, add it to 120 ml of a solution containing 5.2% sodium cellulose sulfate and 1% sodium alginate, stir evenly, and add dropwise to a solution containing 0.2% PDMDAAC and 1% CaCl 2 In the solution, the droplet diameter is 2±0.5mm. , after dropping at 25°C, soak for 15 minutes, take out the obtained microcapsules, wash them with 0.9% NaCl, and set aside.

[0054]Add 4% 1-hydroxyethylamino-1-deoxy-D-sorbitol 3L and 500g bacteria-containing microcapsules into a 10-liter automatic fermentation tank, stir at 30-31°C, 100-150rpm, and maintain pH5. 0~6.0, under the condition of 3.5L / min of air, transform 23~28hr to filter out bacterial microcapsules, add diatomaceous earth and activated carbon to the filtrate, stir for 30 minutes, filter, add 5% Pd / Ni 25g to the filtrate, ~40°C, hydrogenation at 2~5MpA for 5.0~7 hours, the supernatant was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com