Laser processing method and laser processing apparatus

A laser processing method and laser processing technology, which can be used in fine working devices, laser welding equipment, stone processing equipment, etc., can solve problems such as difficulty in improving processing capacity, and achieve the goal of preventing significant reduction, improving processing productivity, and increasing scanning speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

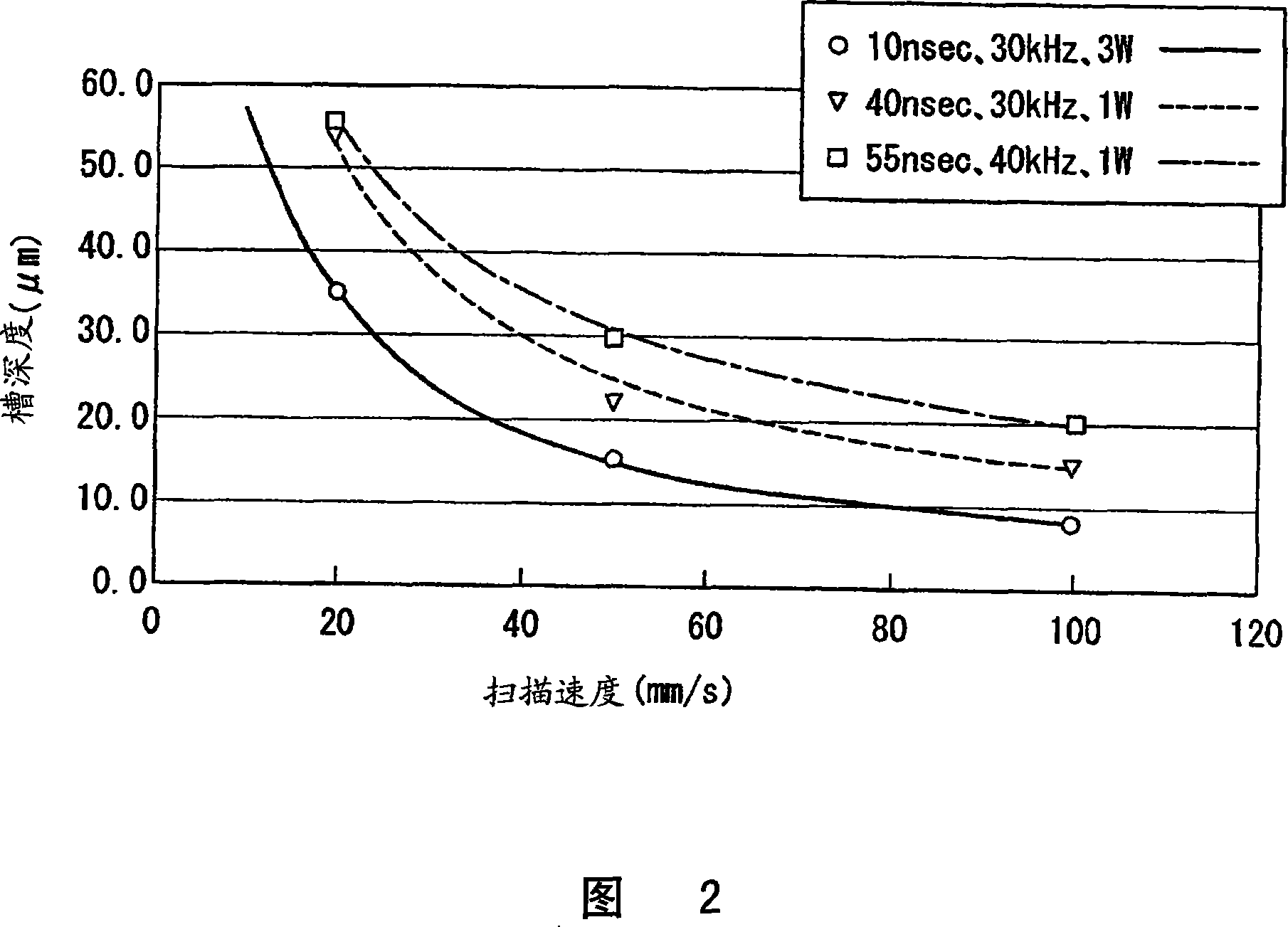

[0057] In the laser processing of the present invention, the processing ability in the case of actually performing grooving processing on an alumina substrate was studied.

[0058] In this embodiment, as shown in Table 1, the groove depth was changed by changing the scanning speed to 20, 50, 100 mm / s for processing.

[0059] As processing conditions, Example (1) in which pulse width, frequency, and average output were set to 40nsec, 30kHz, and 1W, and Example (2) in which pulse width, frequency, and average output were set to 55nsec, 40kHz, and 1W were examined. Furthermore, comparative examples in which the pulse width, frequency, and average output were respectively set to 10nsec, 30kHz, and 3W were studied as conventional processing conditions. Table 1 and Fig. 2 show the results of this study. In addition, the number of traces (trace) is set to 2 times.

[0060] Table 1

[0061] comparative example

Example (1)

Example (2)

scanning speed

(m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com