Product-based bill of material generating method

A bill of materials, product technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as poor usability, low accuracy, and low efficiency, and achieve good usability, high accuracy, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

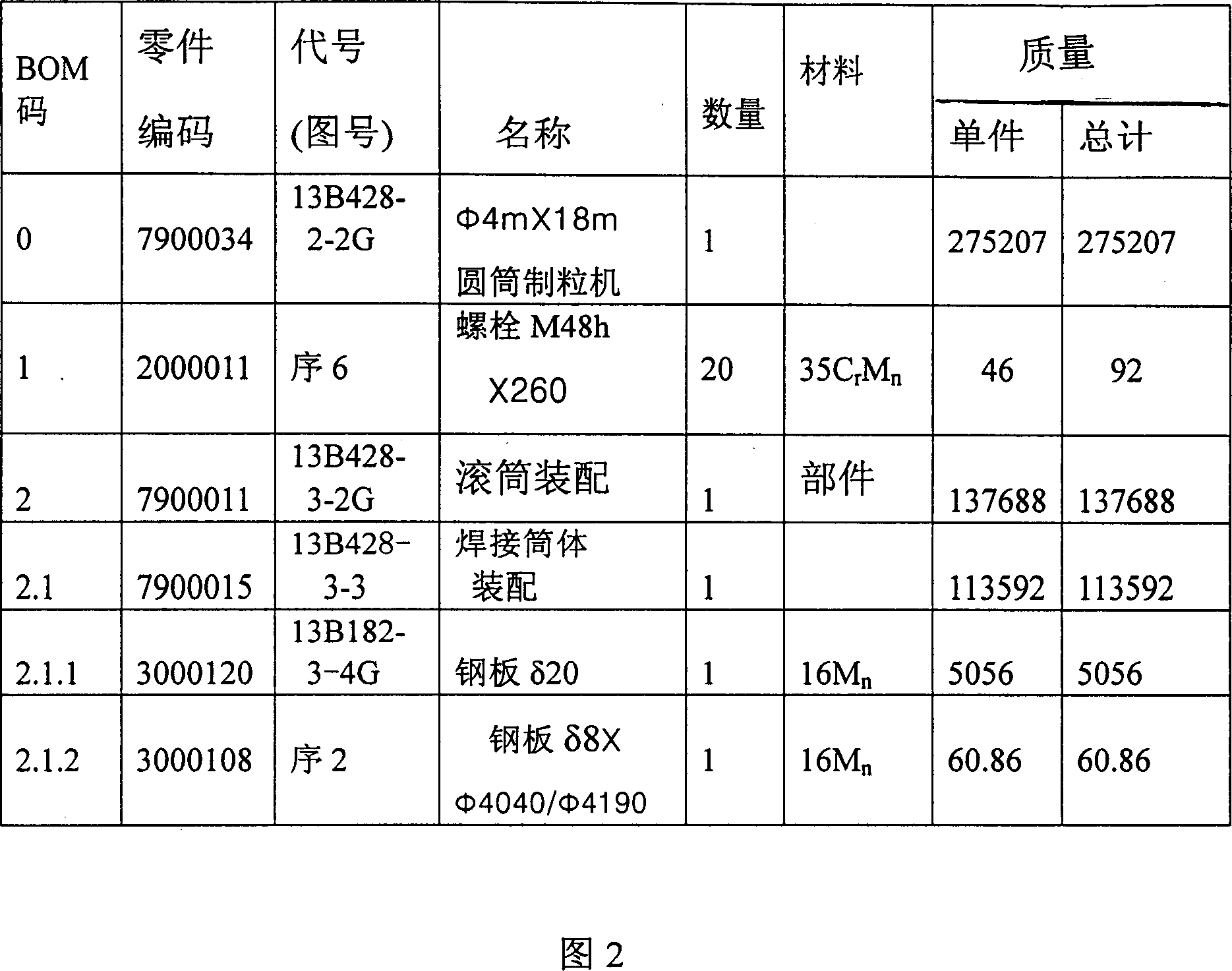

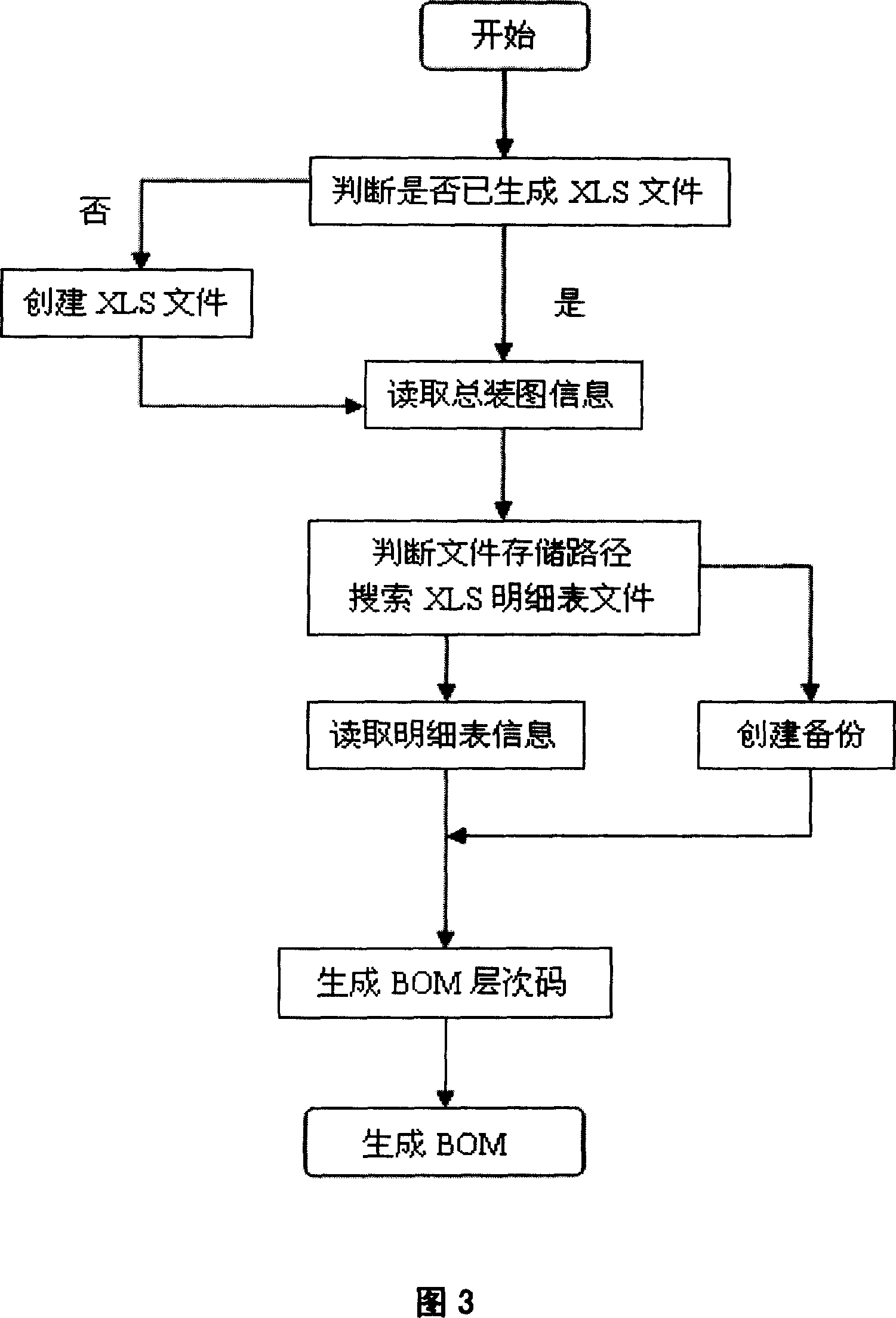

[0018] 1. Generate a detailed list in ".xls" format

[0019] The schedule is an important basis for BOM generation. In most companies, there are generally two ways to manage and archive schedules, one is ".dwg" files, and the other is ".xls" files. Based on Excel's powerful table generation and editing functions, Excel is favored by many manufacturers, and there are many and simple methods for converting ".dwg" format schedules into ".xls" format. Name all relevant Excel files of the detailed list with their respective drawing numbers and parts names, and store them in the same directory.

[0020] 2. Read the general assembly drawing information

[0021] Through computer programming, the relevant detailed list information of the assembly drawing is first summarized into the database, and the read information is sorted and adjusted to prepare for the subsequent BOM generation work.

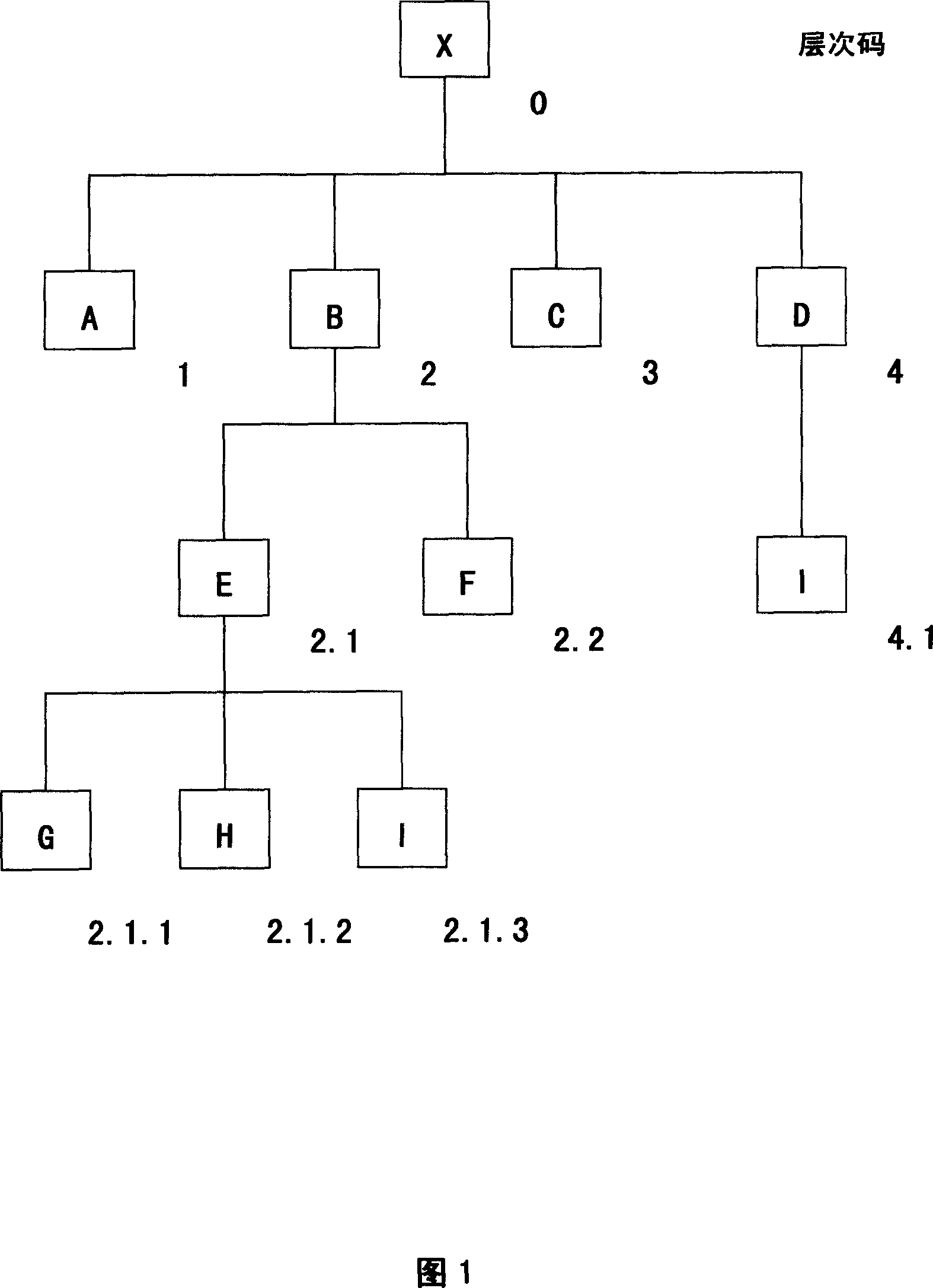

[0022] 3. Unfold according to the final assembly, read the data and code the BOM

[0023] Extract t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com