Multi-stage cooling middle liquid-separation air condensator

An air condenser and condenser technology, which is applied to steam/steam condensers, lighting and heating equipment, etc., can solve the problems of high production and operation costs, decreased fin utilization rate, and poor condensation effect, and achieves a reduction in production and operation costs. and operating costs, avoidance of steam leakage or steam short circuit, the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

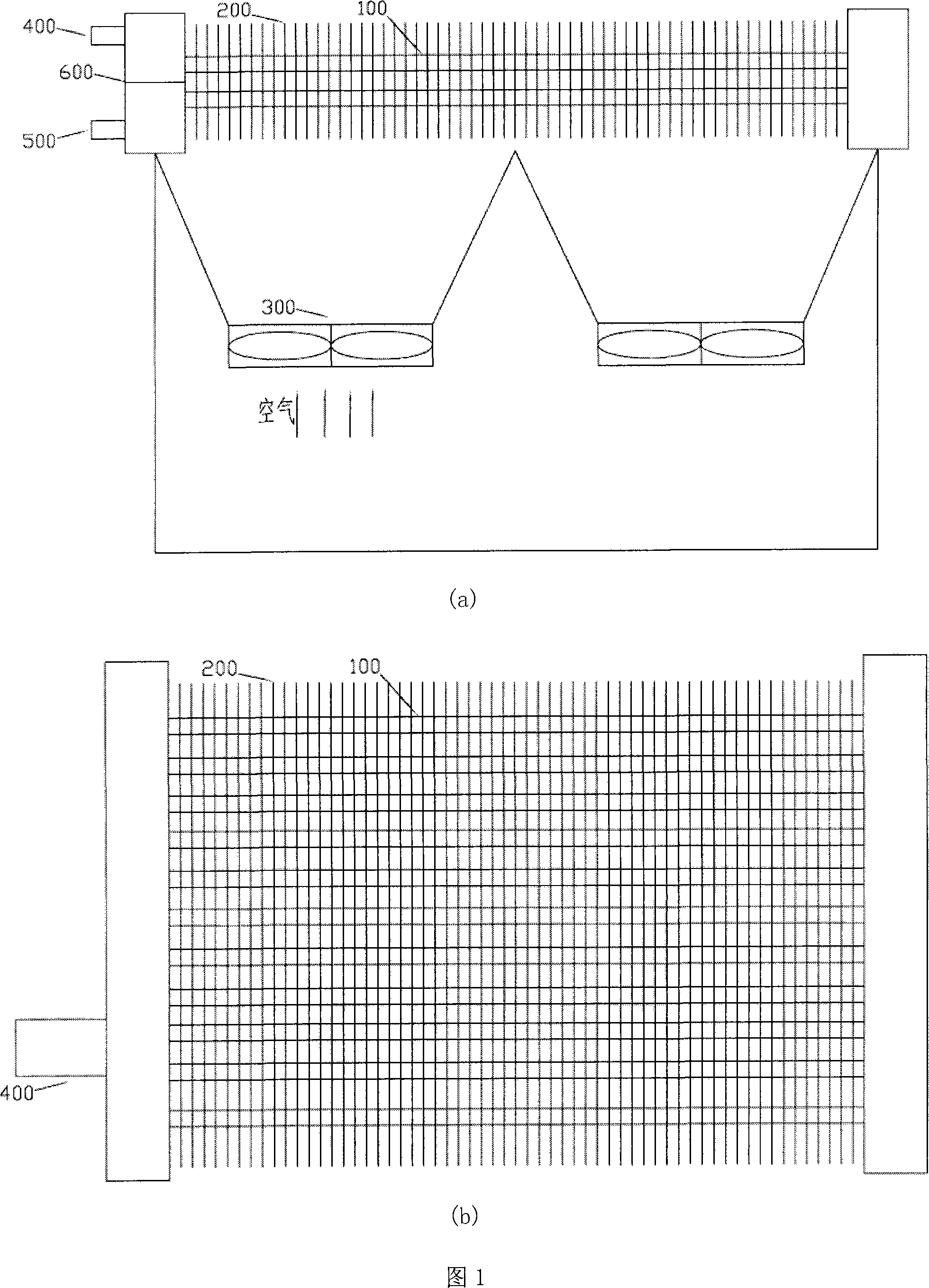

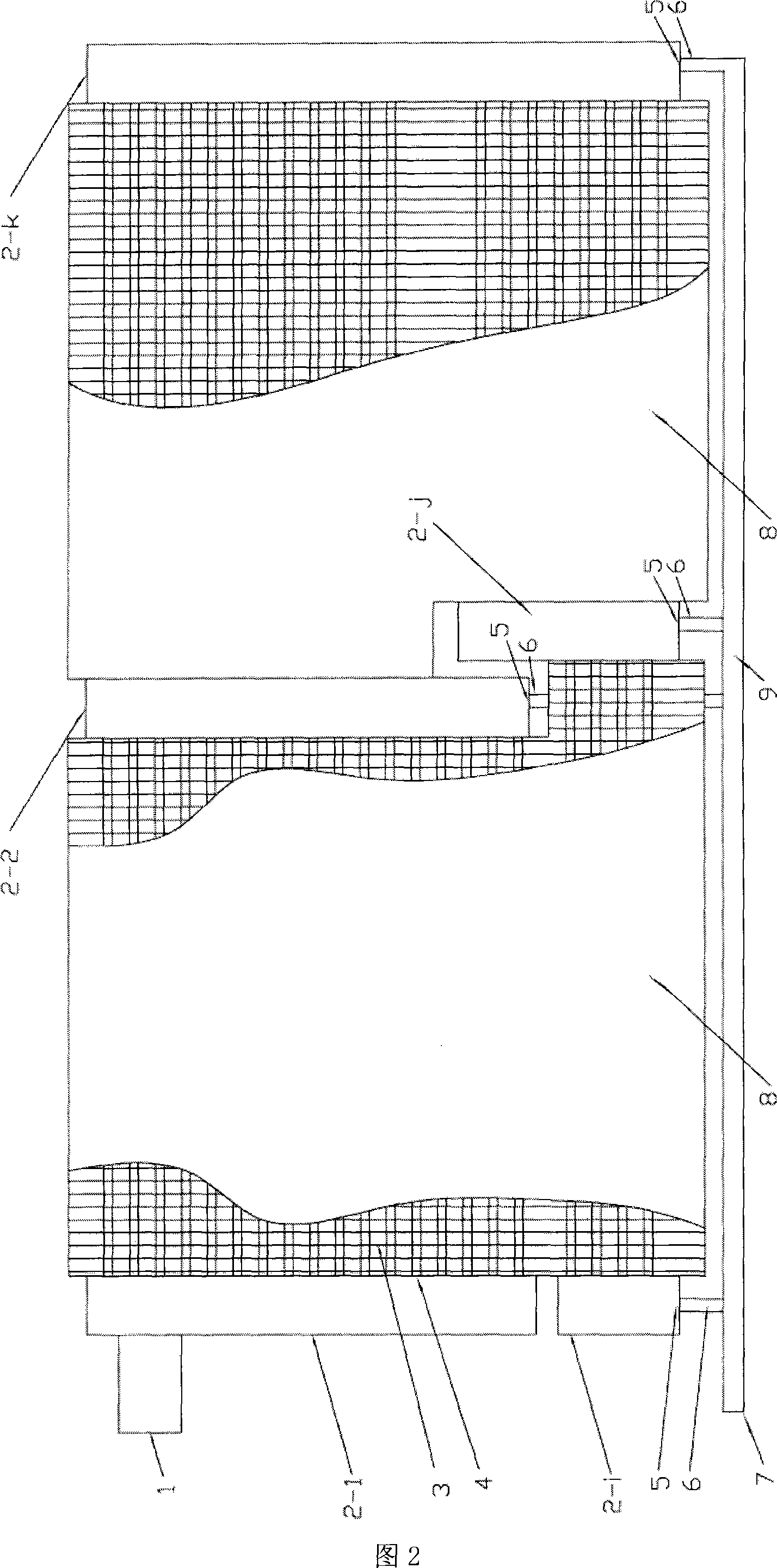

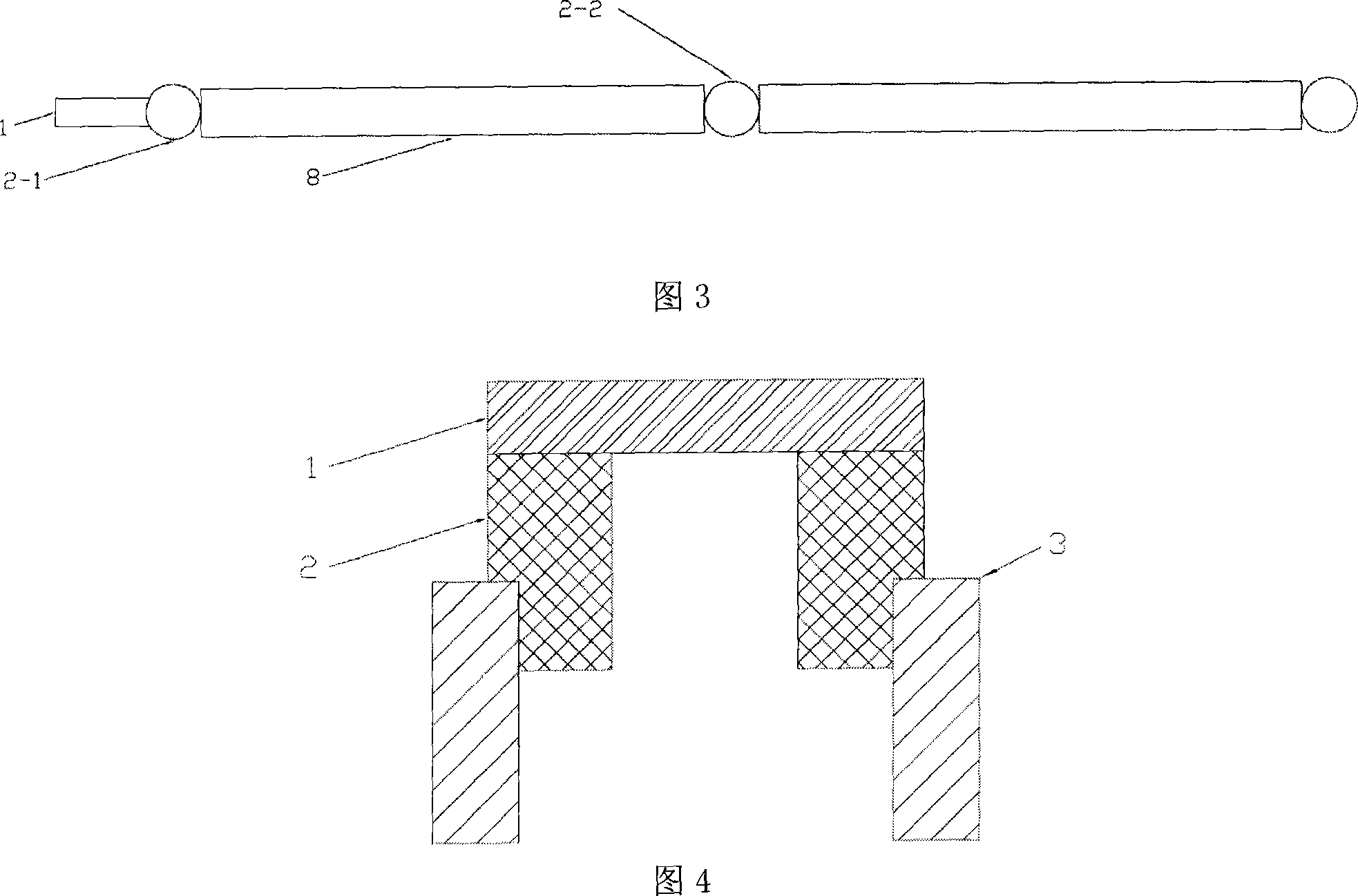

[0023] Fig. 2 is the front view of the present invention (serial horizontal pipe type), wherein, 1 air inlet, 2-j the j header, 2-k single turning header, 2-i the last header, 3 fins , 4 heat exchange tubes, 5 liquid outlet air seal device, 6 liquid discharge pipe, 7 condensate outlet, 8 shell, 9 condensate collecting pipe. A multi-stage cooling intermediate liquid-splitting air condenser, suitable for cooling of large-scale power engineering, composed of multiple stages A, B..., the number of stages can be adjusted according to needs, this picture shows the intermediate separation with two-stage cooling Liquid air condenser. There are headers between the stages to transfer steam. Except for the first stage which includes steam inlet 1 and condensate outlet 7, the rest of the stages only contain headers 2-j, fins 3, heat exchange tubes 4, and liquid outlets. Sealing device 5, dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com