Exhaust structure for small watercraft

A ship and small technology, applied in ship propulsion, exhaust device, ship construction, etc., can solve the problems of complicated shape of the backflow prevention chamber, hinder the cost of suppressing the backflow prevention chamber, etc., and achieve the effect of simplifying the structure and realizing the manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

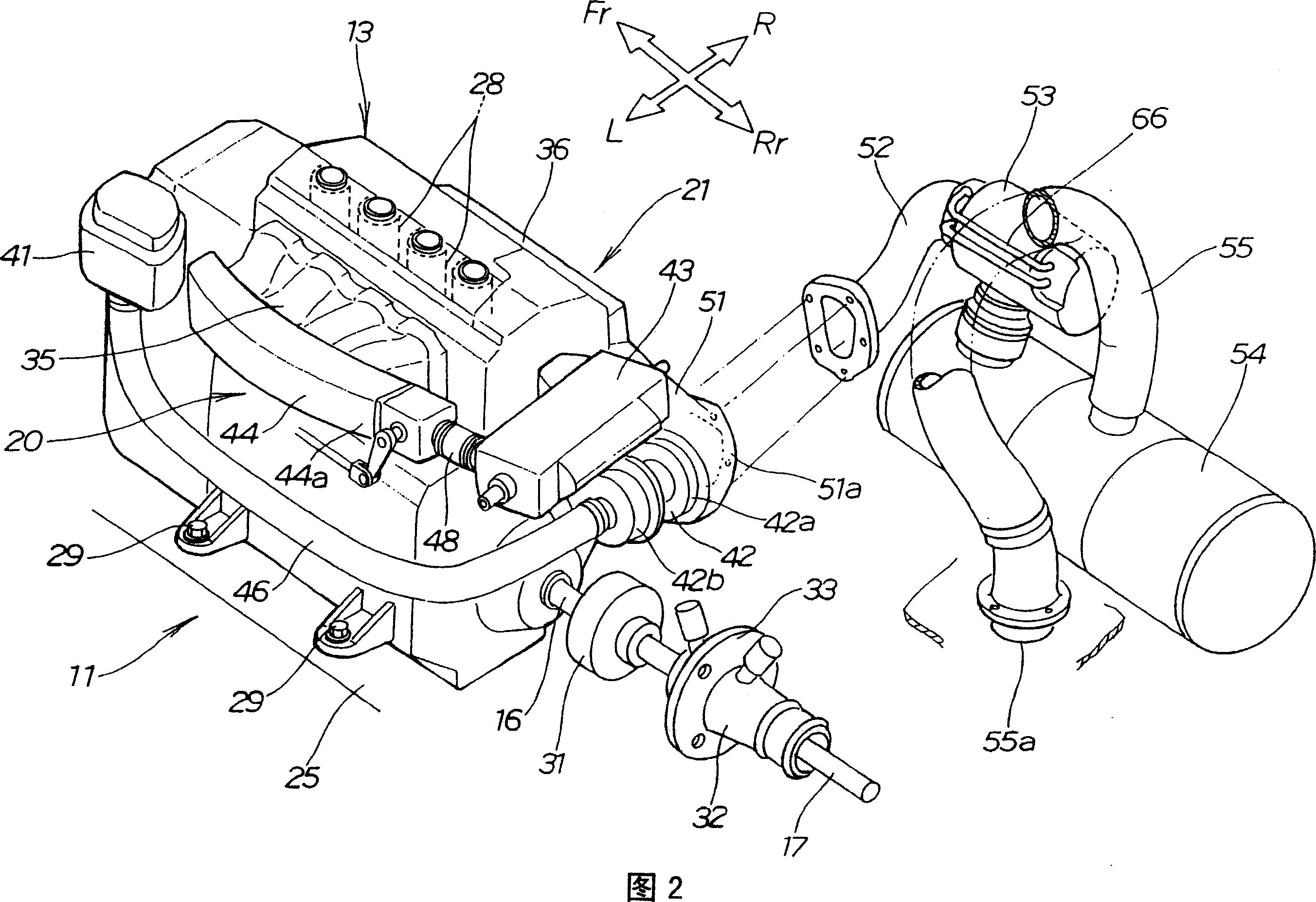

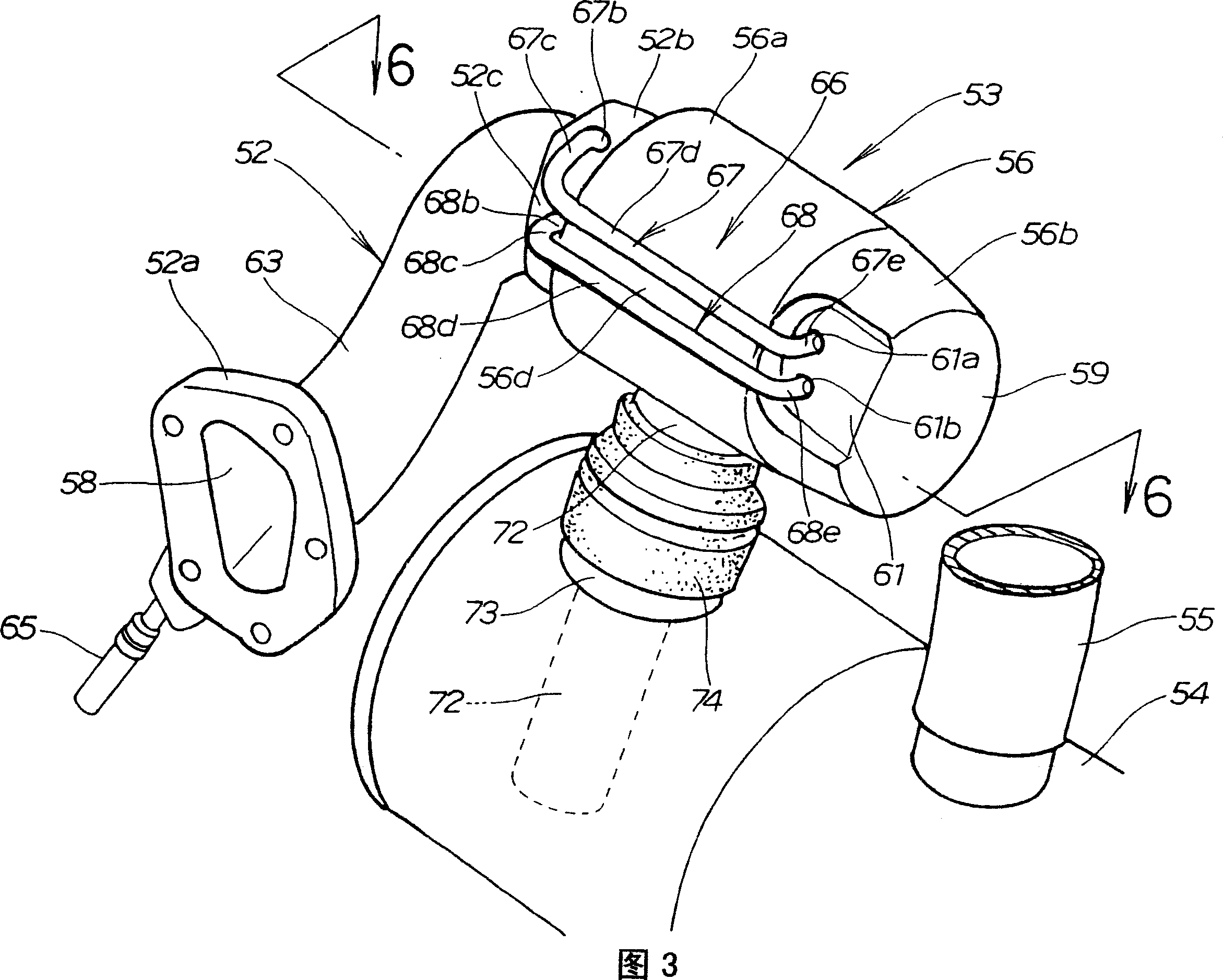

[0036] Hereinafter, the best mode for carrying out the present invention will be described based on the drawings. In addition, "front", "rear", "left", and "right" are the directions that follow the driver's view, and the front side is set as Fr, the rear side is set as Rr, and the left side is set as L, The right side is represented by R.

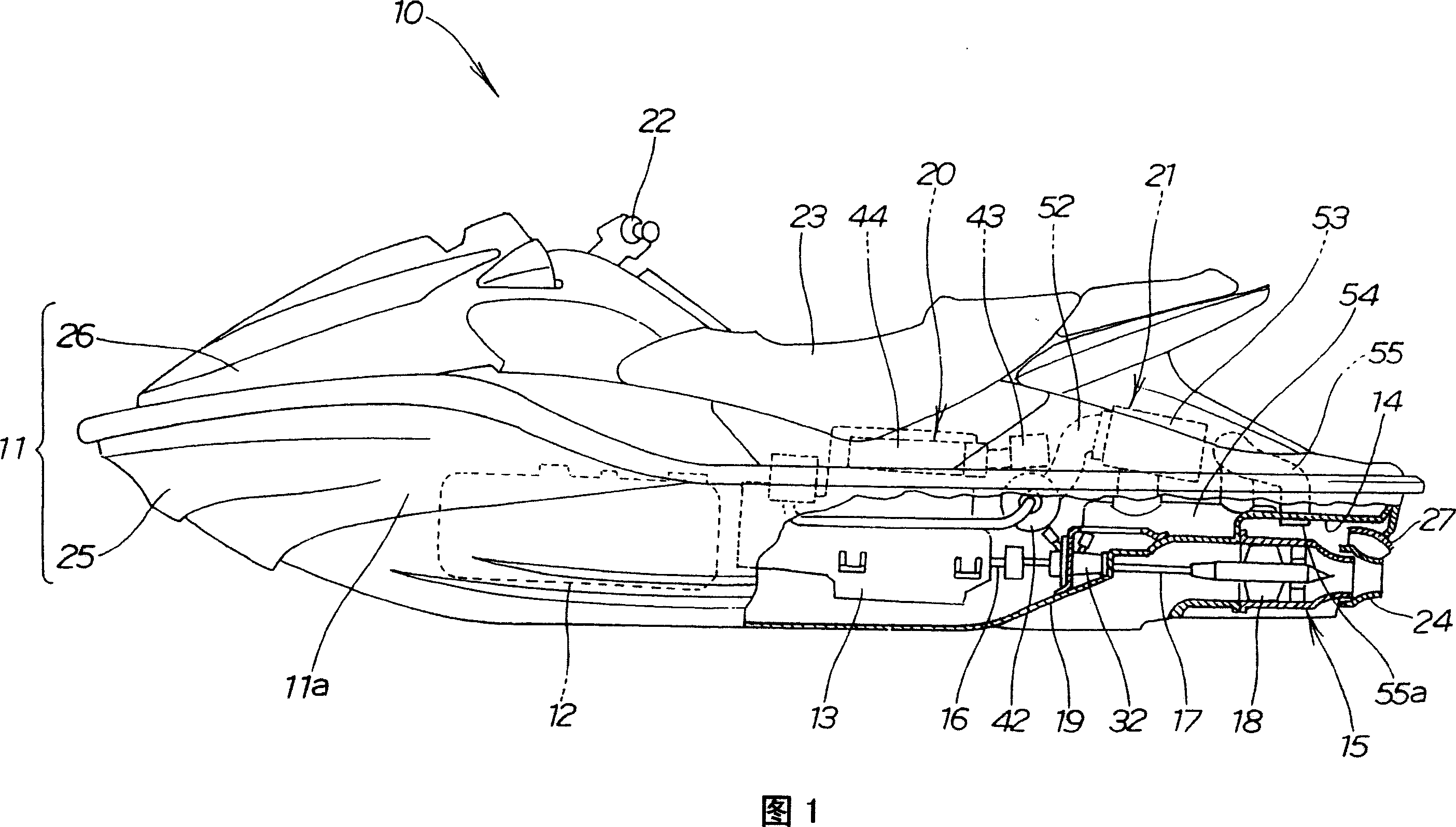

[0037] Fig. 1 is a side view showing a small watercraft according to the present invention.

[0038] Small watercraft 10 is a water jet propulsion boat, which has a fuel tank 12 on the front part 11a of the hull 11, an engine 13 behind the fuel tank 12, and a pump chamber 14 behind the engine 13, in which 14 has a water jet pump 15, has a drive shaft 17 that connects the water jet pump 15 to the output shaft of the engine 13, has an air intake structure 20 that supplies air to the engine 13, and has an exhaust structure that exhausts exhaust gas from the engine (for small ships) Exhaust structure) 21, has a helm handle 22 above the fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com