Sensitive material and formaldehyde sensitive component produced with sensitive material and method for producing sensitive component

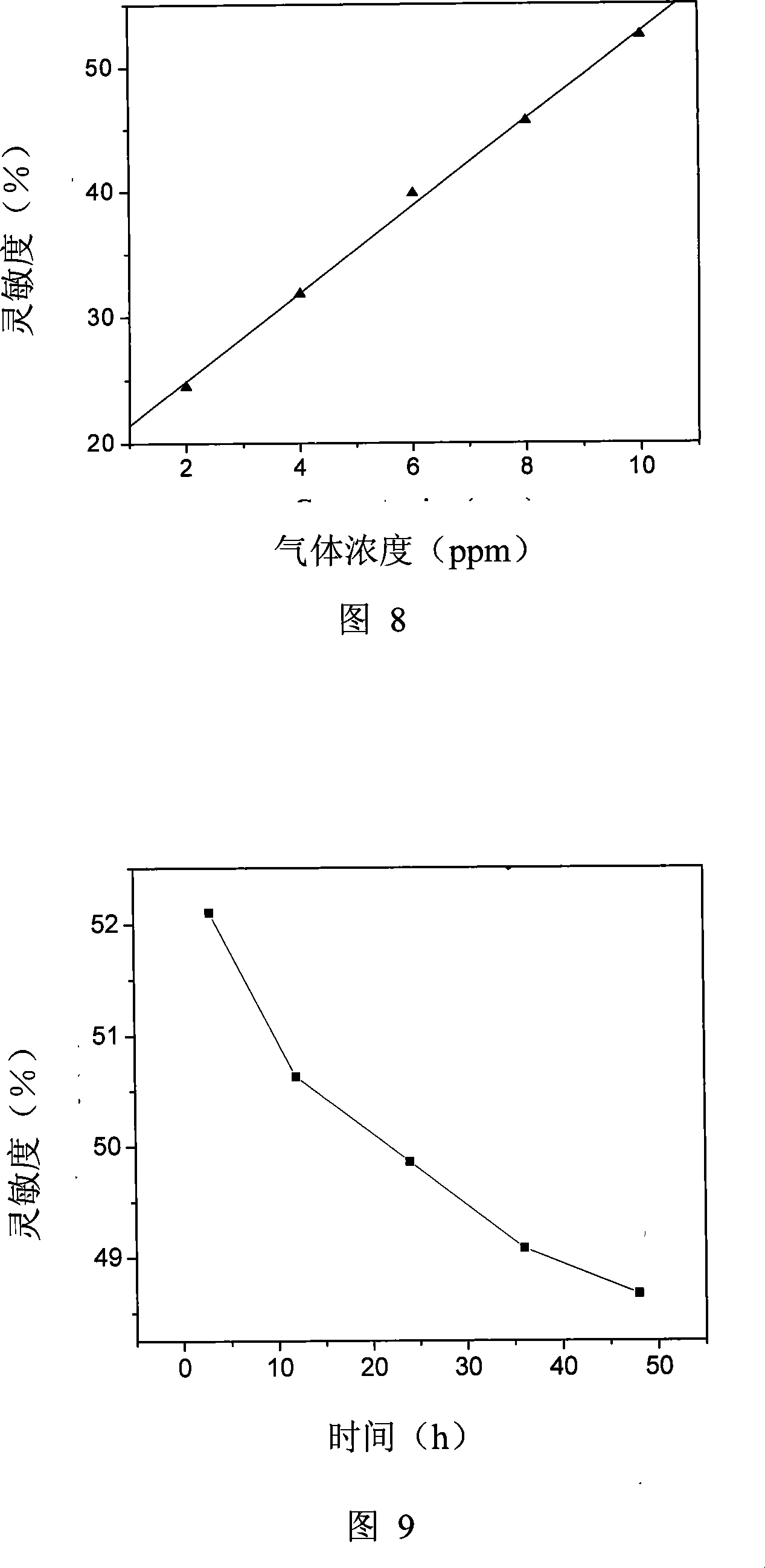

A technology of sensitive materials and sensitive components, which is applied in the direction of analyzing materials, analyzing materials through electromagnetic means, measuring devices, etc., can solve the problems of long recovery time, high working temperature, long response time, etc., and achieve improved stability and good stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

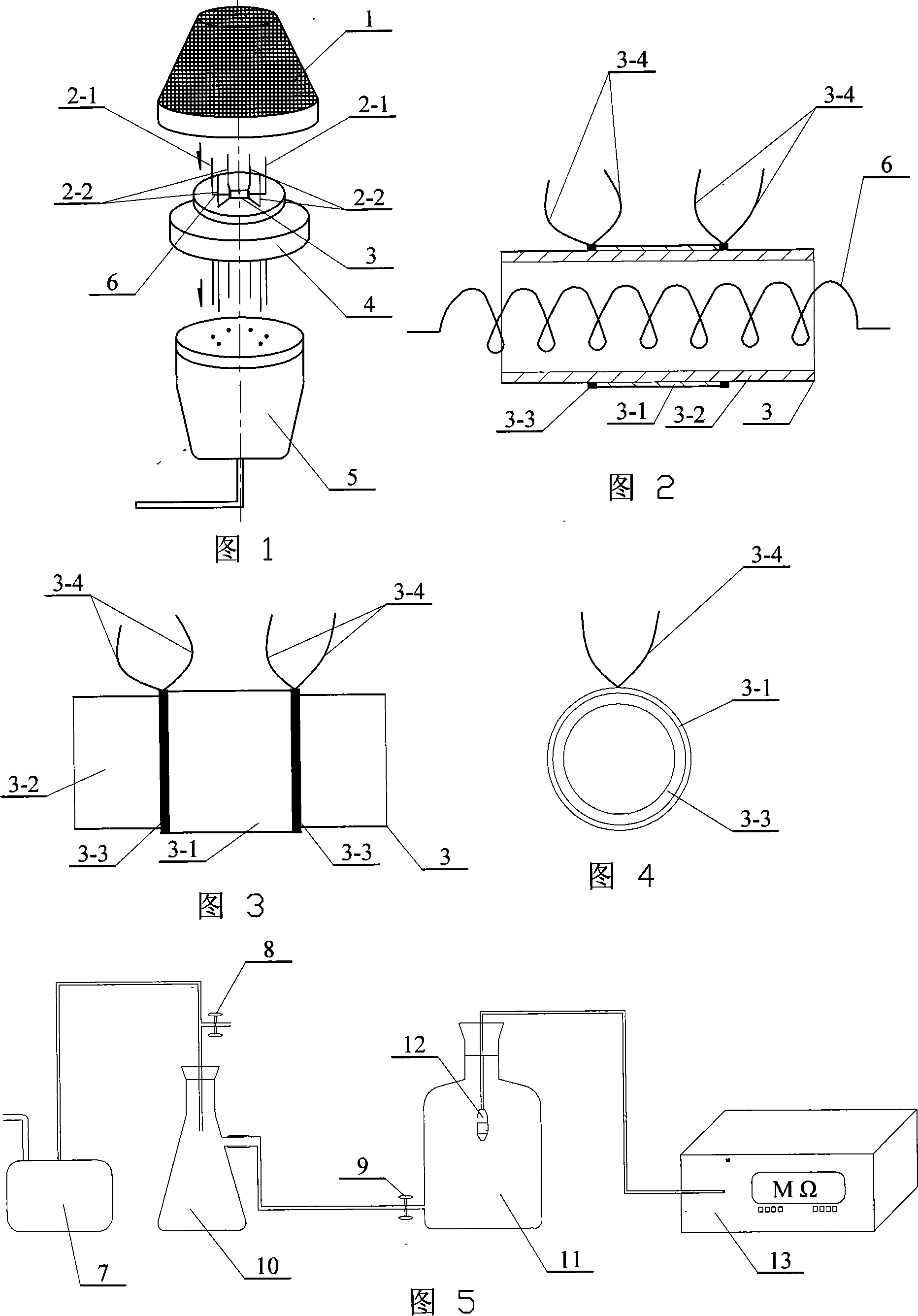

Method used

Image

Examples

specific Embodiment approach 1

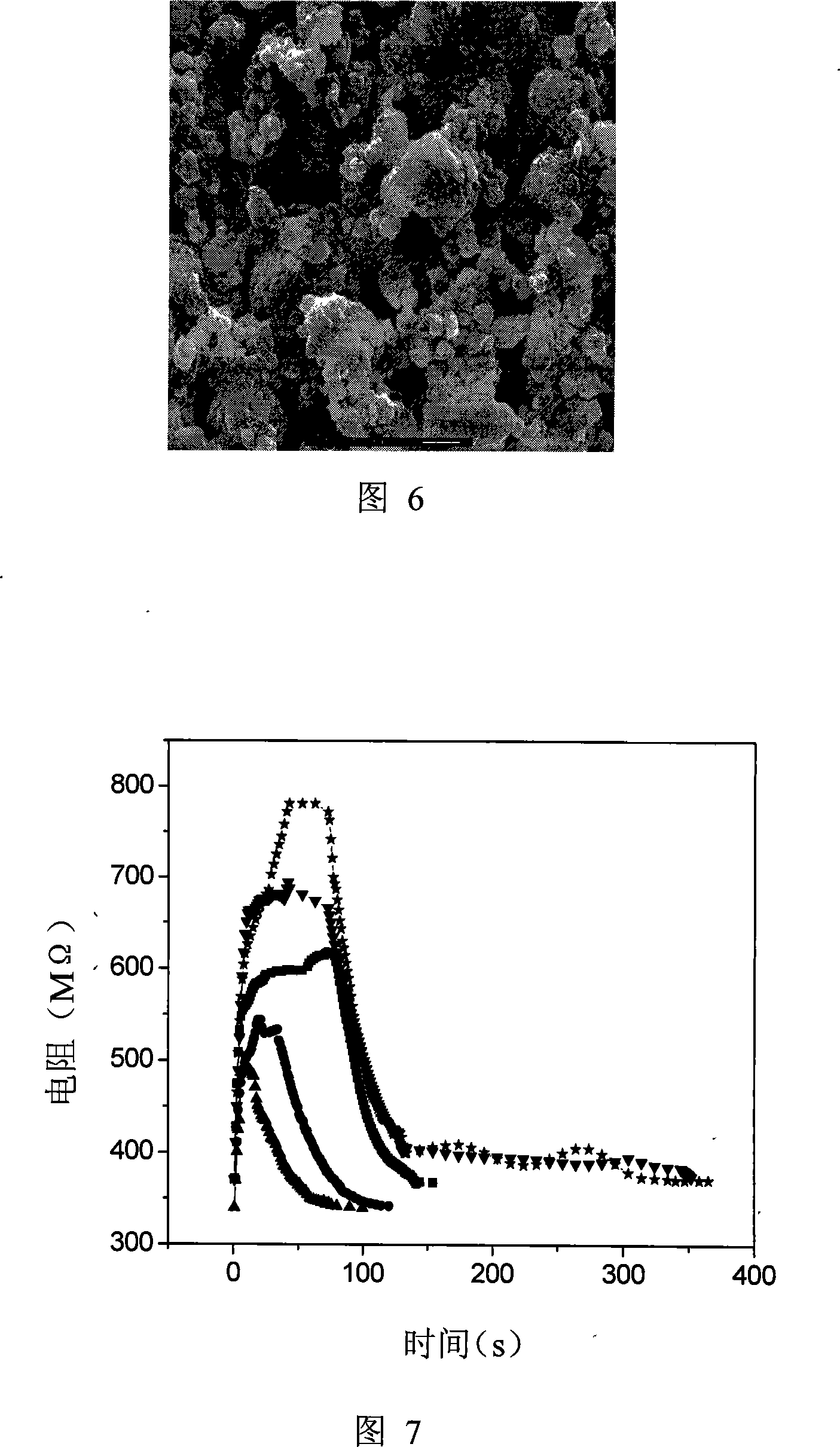

[0014] Specific embodiment one: the general formula of the sensitive material in this embodiment is B 2-a A b o 3 , wherein A is Sn, Pb, Ti or Zr, B is Mo, W, Cr or Mn, 0

[0015] The sensitive material in this embodiment is prepared by a conventional combustion method.

specific Embodiment approach 2

[0016] Embodiment 2: In this embodiment, A is Pb, Ti or Zr. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0017] Embodiment 3: In this embodiment, B is Mo, Cr or Mn. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com