Microwave process of synthesizing lithium dioxalate borate

A technology of bis-oxalate lithium borate and microwave method, applied in the field of lithium borate, can solve the problems such as LiBOB that have not been seen, and achieve the effects of short synthesis time, less impurities and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

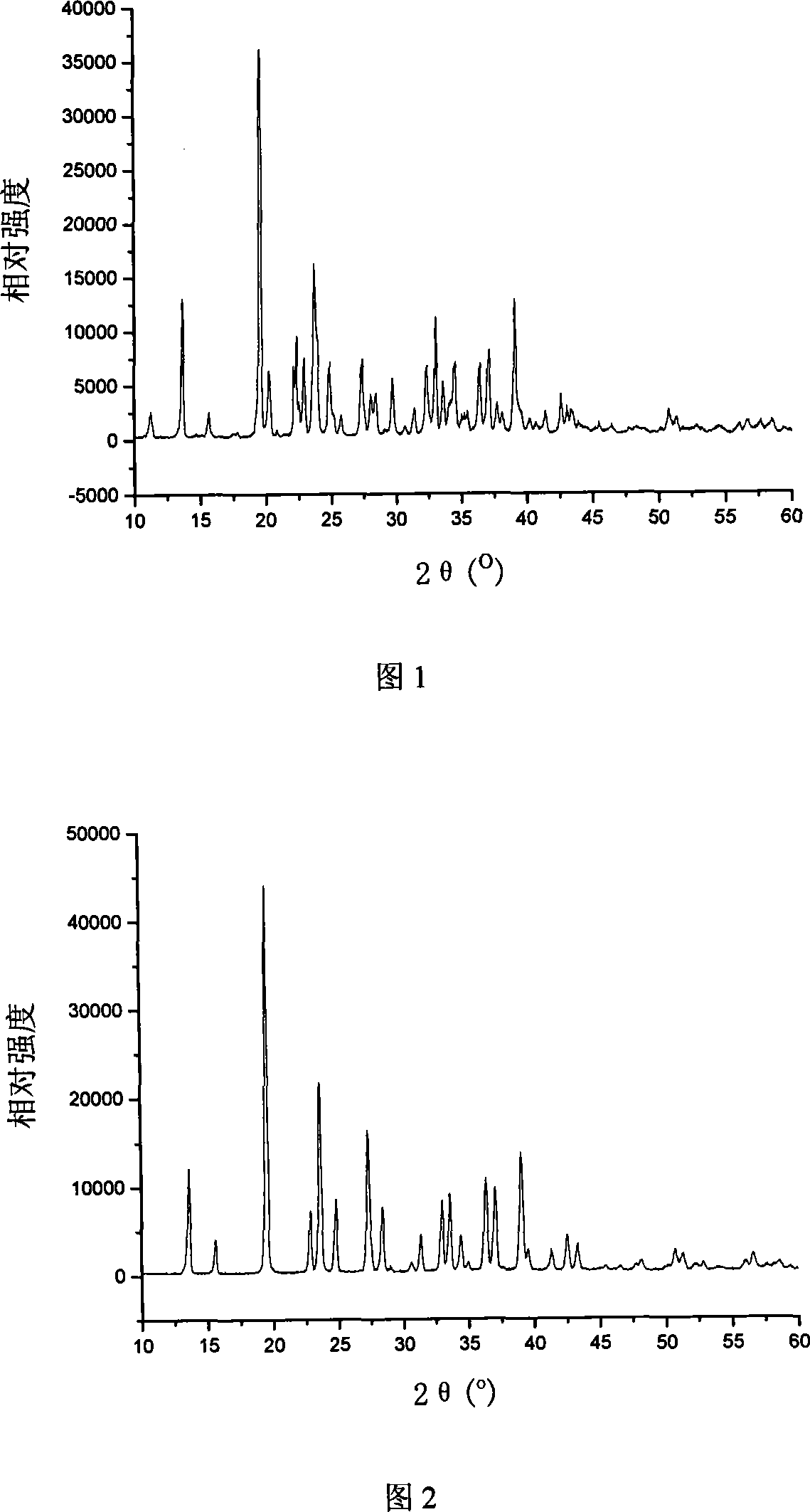

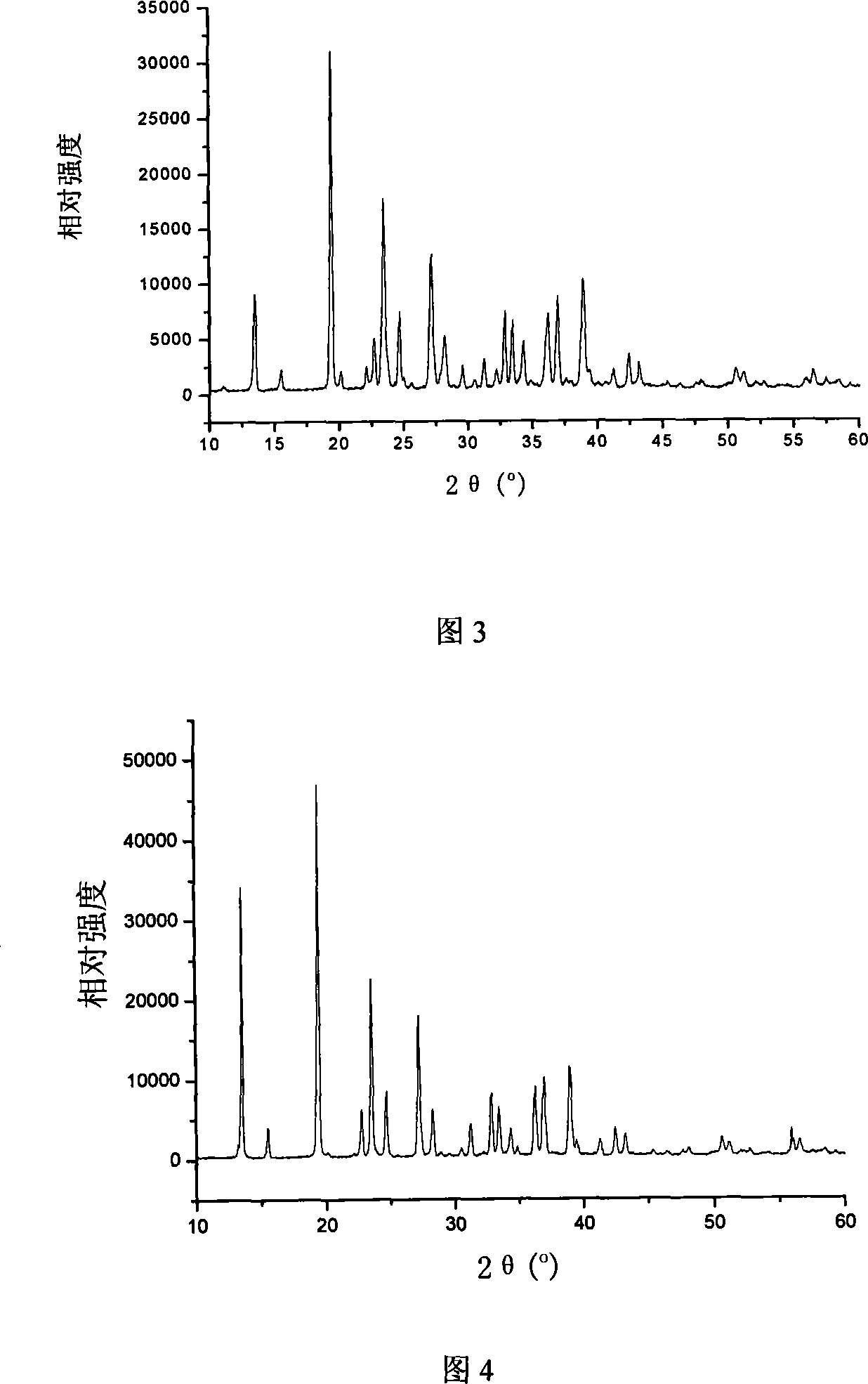

[0021] Press H 2 C 2 o 4 2H 2 O: LiOH·H 2 O:H 3 BO 3 =2.1:1:1 ratio, weigh H 2 C 2 o 4 2H 2 O 13.23 g, LiOH·H 2 O 2.1 g, mechanically mixed for 2 min before adding H 3 BO 3 3.09 g, continue mixing for 3 minutes. Put the mixed material into a beaker, then put the beaker in a microwave oven, adopt 160W, the first section is 5 minutes, heat preservation is 10 minutes, and the second section is 9 minutes to synthesize LiB(C 2 o 4 ) 2 , as can be seen from the XRD pattern, the synthesized product is basically LiB(C 2 o 4 ) 2 , but contains a small amount of impurities. There is no impurity peak in the XRD figure of the product after one purification. The results are shown in Figure 2.

Embodiment 2

[0023] Press H 2 C 2 o 4 2H 2 O: LiOH·H 2 O:H 3 BO 3 =2.2:1:1 ratio, weigh H 2 C 2 o 4 2H 2 O 27.87 g, LiOH·H 2 O 4.2 g, mechanically mixed for 3 min before adding H 3BO 3 6.214 grams, continue mixing for 4 minutes. Put the mixture into the beaker, then put the beaker into the microwave oven, the first section of 160W, 5 minutes, keep warm for 10 minutes. The second stage 160W 25 minutes, keep warm for 10 minutes. The XRD pattern of the synthesized product is shown in Figure 3. Comparing Figure 1 and Figure 3, it can be seen that increasing the proportion of oxalic acid and increasing the intermediate stirring link are conducive to reducing the content of impurities.

Embodiment 3

[0025] Press H 2 C 2 o 4 2H 2 O: LiOH·H 2 O:H 3 BO 3 =2.1:1:1 ratio, weigh H 2 C 2 o 4 2H 2 O 27.87 g, LiOH·H 2 O 4.2 g, mechanically mixed for 3 min before adding H 3 BO 3 6.214 grams, continue mixing for 4 minutes. Put the mixture into a beaker, then put the beaker into the microwave oven, the first stage is 210W, 5 minutes, keep warm for 10 minutes, stir once between the two stages. The second stage is 330W for 30 minutes, and keep warm for 10 minutes. The XRD pattern of the synthesized product is shown in Figure 4. Comparing Figure 3 and Figure 4, it can be seen that increasing the microwave power is beneficial to reduce the content of impurities.

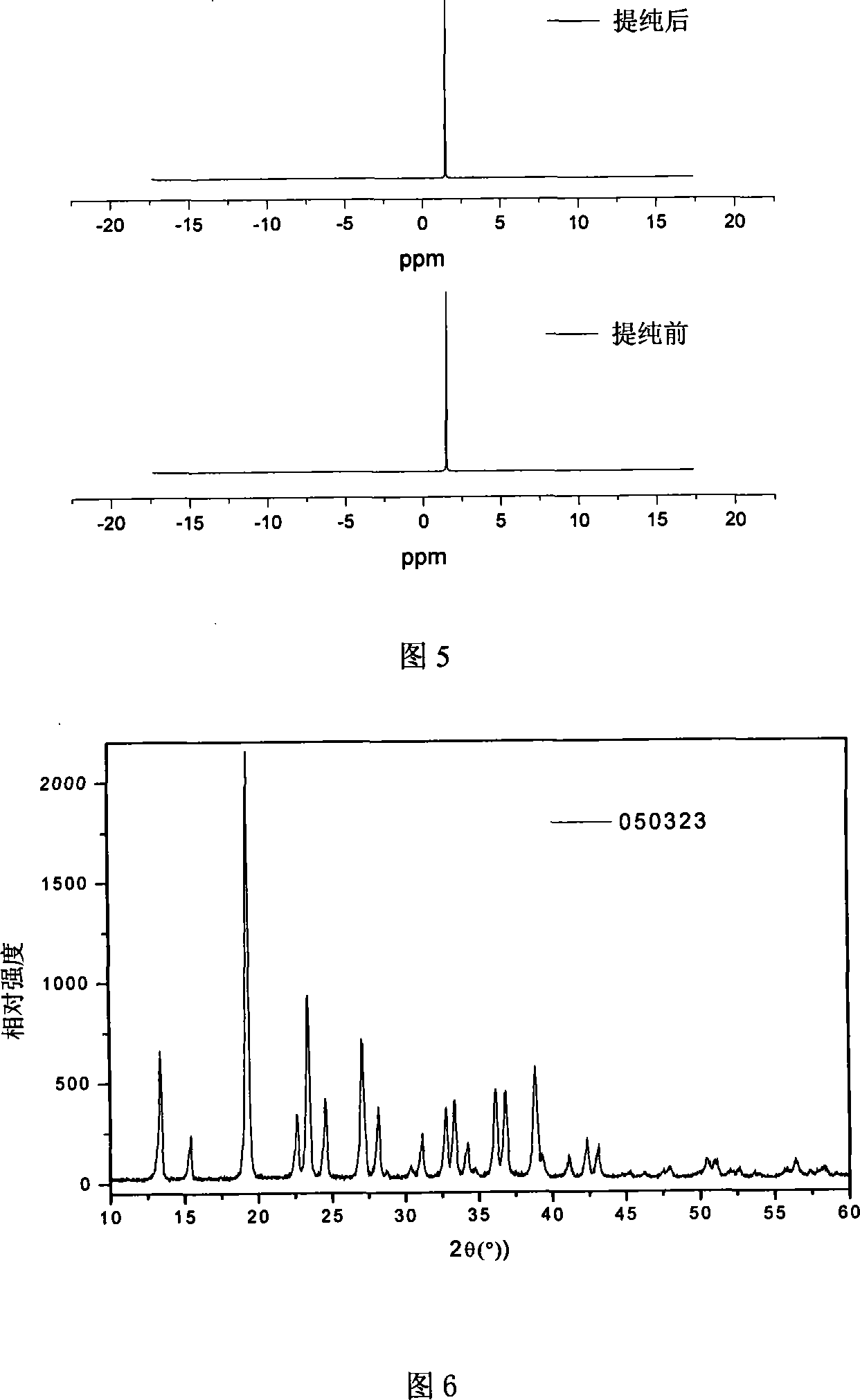

[0026] Fig. 5 is the NMR boron spectrum before and after the purification of the product of Example 3, as can be seen, the product before purification does not have any impurity peaks except a B main peak of LiBOB, indicating that the product does not contain boron impurities at this time, and it shows as Less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com