New-type of inorganic bone grafting material and its prepn and use

An inorganic and bone-grafting technology, applied in the field of new inorganic bone-grafting materials and composite artificial inorganic bone cement, can solve the problems of fast absorption, soft tissue filling, slow dissolution and absorption, etc., and achieve convenient storage and use, and good bone defect repair , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

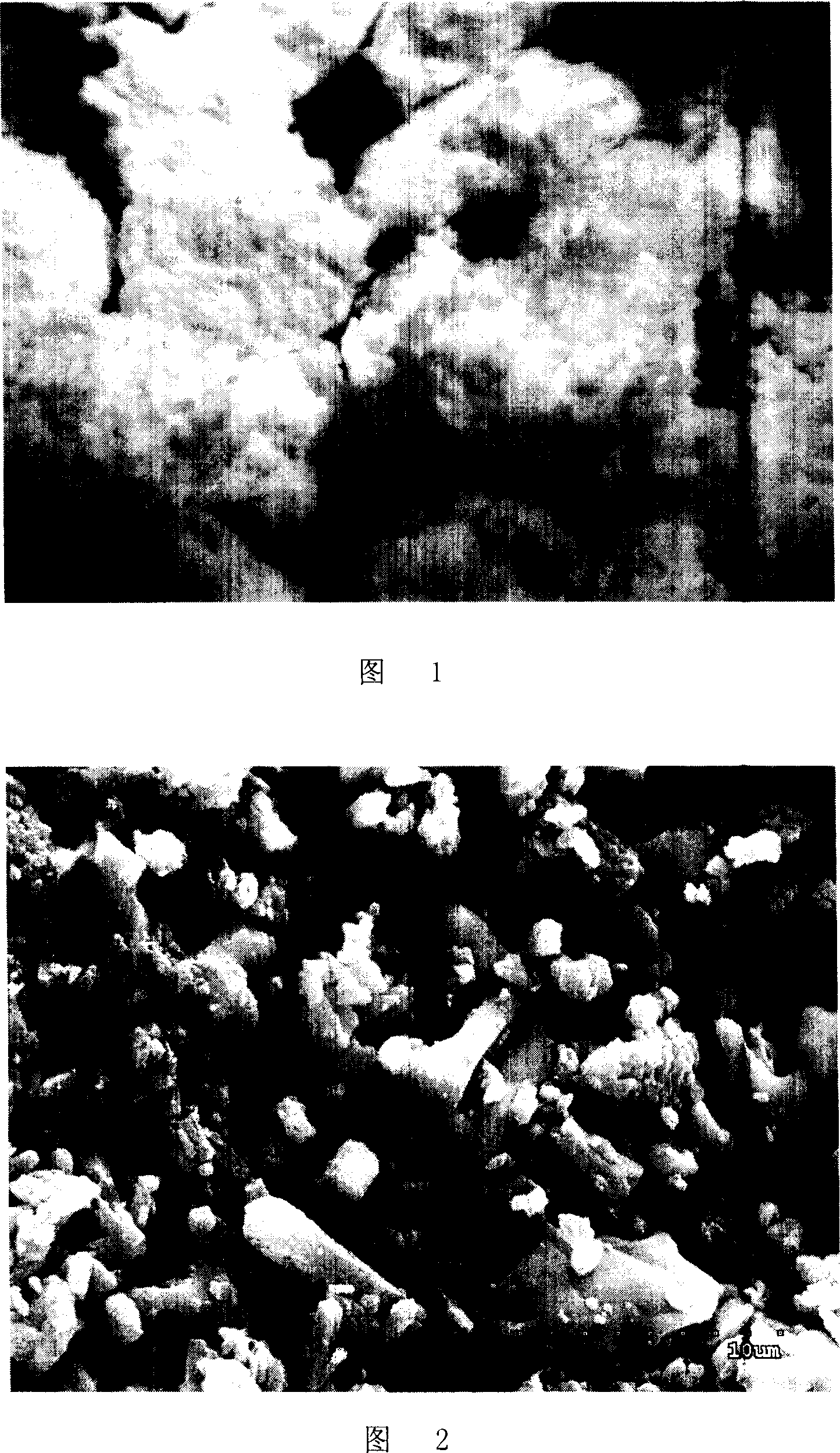

[0038] 1. Preparation of β-tricalcium phosphate particles with a microporous structure: take healthy bovine cancellous bone and crush it into particles with a diameter of 2-3mm, rinse it and calcinate it in a high-temperature furnace at 800°C for 3 hours, take it out and soak it in a concentration of 1M of (NH 4 ) 2 HPO 4 Put in the solution for 24 hours, dry at 50°C for 4 days, put it in a high-temperature calciner at 1100°C for 1 hour, heat up at a rate of 5°C / min, slowly cool down, rinse with deionized water twice, and dry at 50°C for 4 days to prepare The main ingredient is granules of β-tricalcium phosphate. The pellets have been stripped of organic matter. The diameter of the particles was 4 mm.

[0039] 2. Preparation of α-calcium sulfate hemihydrate powder: put analytically pure calcium sulfate dihydrate in a closed high-pressure reactor with a steam pressure of 0.13Mpa and heat it to 123°C, heat it at a constant temperature for 7 hours, and then take out the elect...

Embodiment 2

[0042] 1. Preparation of β-tricalcium phosphate particles with a microporous structure: take healthy bovine cancellous bone and crush it into particles with a diameter of 2-3mm, rinse it and calcinate it in a high-temperature furnace at 800°C for 3 hours, take it out and soak it in a concentration of 1M of (NH 4 ) 2 HPO 4 Put in the solution for 24 hours, dry at 50°C for 4 days, put it in a high-temperature calciner at 1100°C for 1 hour, heat up at a rate of 5°C / min, slowly cool down, rinse with deionized water twice, and dry at 50°C for 4 days to prepare The main ingredient is granules of β-tricalcium phosphate. The pellets have been stripped of organic matter. The diameter of the particles was 10 mm.

[0043] 2. Preparation of α-calcium sulfate hemihydrate powder: put analytically pure calcium sulfate dihydrate in a closed high-pressure reactor with a steam pressure of 0.13Mpa and heat it to 123°C, heat it at a constant temperature for 7 hours, and then take out the elec...

Embodiment 3

[0046] 1. Preparation of β-tricalcium phosphate particles with a microporous structure: 2 parts by weight of calcium hydrogen phosphate was converted into calcium pyrophosphate at 800°C for 3 hours, then mixed with 1 part by weight of calcium carbonate and pressed into tablets, 1100 After 1 hour under the condition of ℃, cool slowly, and make β-tricalcium phosphate powder after pulverization, and adopt microporous foaming technology (conventional method) to make β-tricalcium phosphate particles with microporous structure. The diameter of the particles is 0.2 mm.

[0047] 2. Preparation of α-calcium sulfate hemihydrate powder: put analytically pure calcium sulfate dihydrate in a closed high-pressure reactor with a steam pressure of 0.13Mpa and heat it to 123°C, heat it at a constant temperature for 7 hours, and then take out the electric heating ventilator placed at 120°C Dry in a drying oven for 4-5 hours, and use a jet mill to pulverize the obtained material into α-sulfuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com