Water soluble silymarin and its prepn

A silymarin and water-soluble technology, which is applied in the field of drug synthesis, can solve the problems such as the absence of water-soluble silymarin, and achieve the effect of enhancing water-solubility, avoiding difficult absorption, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

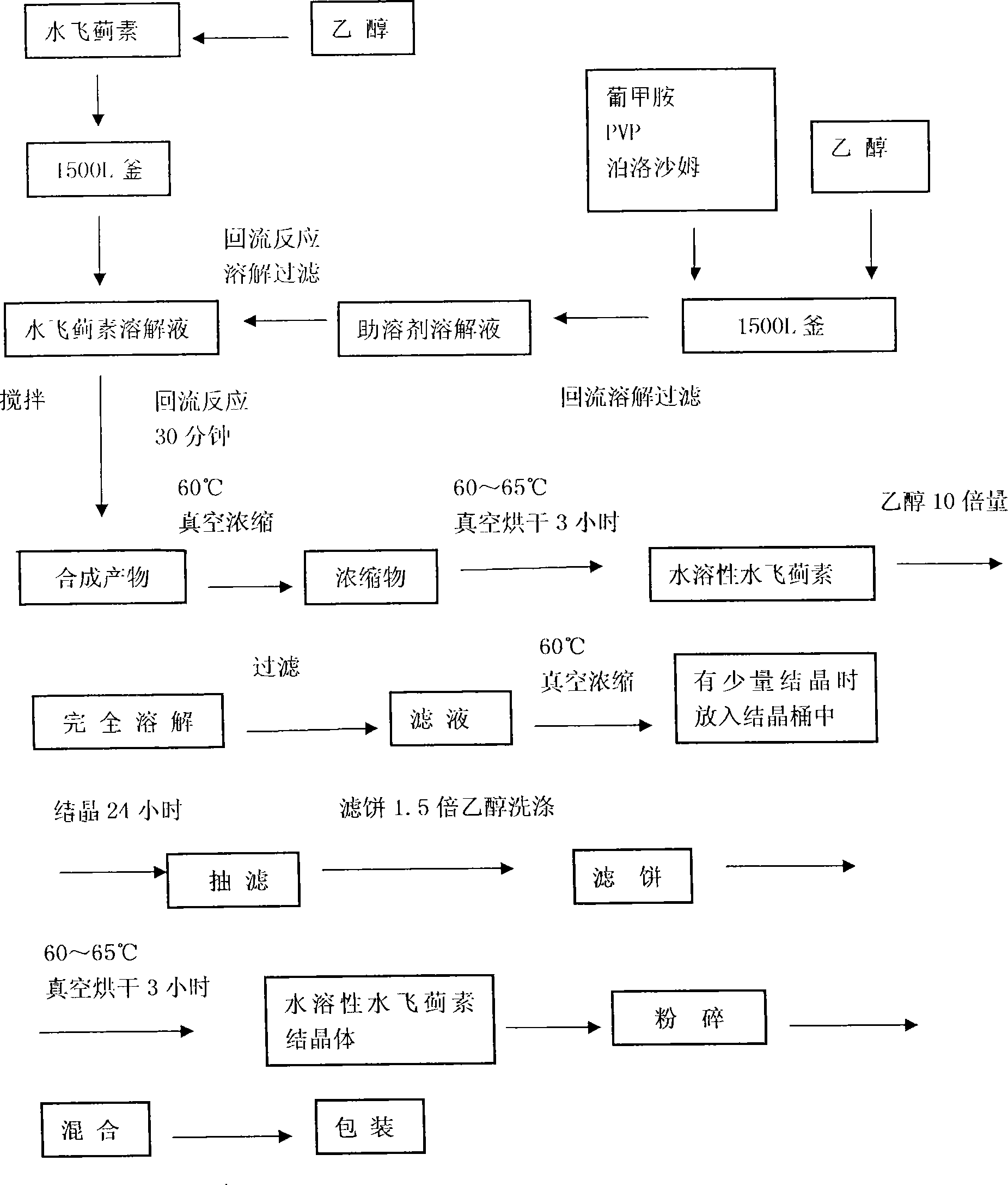

Method used

Image

Examples

Embodiment 1

[0045]First put 3 kg of silymarin into the synthesis tank, dissolve it completely with ethanol and filter it, then dissolve 1.5 kg of meglumine, 0.7 kg of polyvinylpyrrolidone (PVP), and 0.3 kg of poloxamer 188 with ethanol, then filter it and add it while it is hot Mix and stir in the silymarin solution for 30 minutes, the temperature of the solution in the tank is 78°C, and reflux for 30 minutes after stirring, the temperature of reflux is 78°C, after the reaction, the solvent in the synthesis tank is concentrated in vacuum to obtain 7.3 kg of fluid extract, the temperature 60°C, vacuum degree -0.05Mpa, then put the liquid extract into the drying tank, preheat at 70-75°C for 30 minutes, start vacuuming, when the vacuum degree reaches -0.09Mpa, the temperature in the tank is 60-65 5.5 kilograms of water-soluble silymarin dry extracts were obtained after starting to dry for 3 hours at ℃, and the obtained water-soluble silymarin dry extracts were put back into the synthesis tank...

Embodiment 2

[0048] First put 5 kg of silymarin into the synthesis tank, dissolve it completely with ethanol and filter it, dissolve 2 kg of meglumine, 1 kg of polyvinylpyrrolidone (PVP), and 0.5 kg of poloxamer 188 with ethanol, then filter it and add it while it is hot Mix and stir in the silymarin solution for 30 minutes. The temperature of the solution in the tank is 78°C. After stirring, it is refluxed for 30 minutes. The temperature of reflux is 78°C. After the reaction, the solvent in the synthesis tank is vacuum concentrated to obtain 11.6 kg of liquid extract. 60°C, vacuum degree -0.05Mpa, then put the liquid extract into the drying tank, preheat at 70-75°C for 30 minutes, start vacuuming, when the vacuum degree reaches -0.09Mpa, the temperature in the tank is 60-65 8.6 kilograms of water-soluble silymarin dry extracts were obtained after starting to dry for 3 hours at ℃, and the obtained water-soluble silymarin dry extracts were put back into the synthesis tank, and ethanol was ad...

Embodiment 3

[0051] First put 7 kg of silymarin into the synthesis tank, dissolve it completely with ethanol and filter it, then dissolve 3 kg of meglumine, 1.5 kg of polyvinylpyrrolidone (PVP), and 0.8 kg of poloxamer 188 with ethanol, then filter it and add it while it is hot Mix and stir in the silymarin solution for 30 minutes, the temperature of the solution in the tank is 78°C, and reflux for 30 minutes after stirring, the temperature of reflux is 78°C, after the reaction, the solvent in the synthesis tank is concentrated in vacuum to obtain 16.5 kg of fluid extract, the temperature 60°C, vacuum degree -0.05Mpa, then put the liquid extract into the drying tank, preheat at 70-75°C for 30 minutes, start vacuuming, when the vacuum degree reaches -0.09Mpa, the temperature in the tank is 60-65 12.5 kilograms of water-soluble silymarin dry extracts were obtained after drying for 3 hours at ℃, and the obtained water-soluble silymarin dry extracts were re-dropped into the synthesis tank, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com