Prepn of composite mango juice beverage

A technology for compounding fruit juice and mango, applied in the directions of food preparation, application, food science, etc., can solve the problems of prolonging the processing cycle, increasing the workload, unfavorable fruit juice flavor, etc., and achieving the effects of excellent flavor, good stability and excellent flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

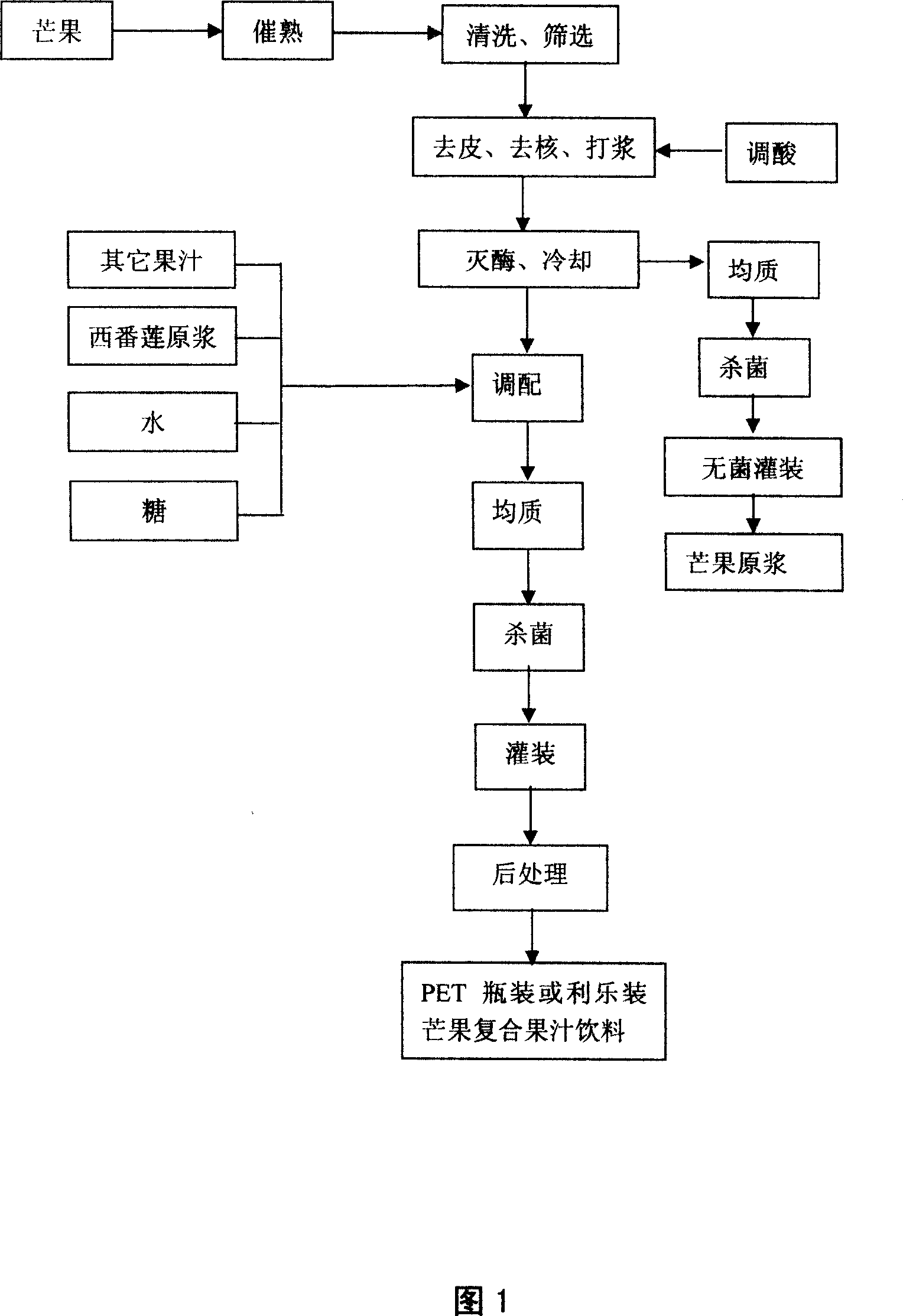

[0025] The preparation method of the mango compound fruit juice drink of the present invention is different from other processes in that citric acid solution is added when the mangoes are crushed and beaten, and the pH value of the fruit pulp is adjusted to between 3.5 and 4.0; Enzyme and cooling, beating and heat exchange are carried out in a completely closed space, and the enzyme is rapidly cooled after the enzyme is eliminated; the enzyme activity is inhibited during the production process, and the target of the enzyme is the pectin decomposing enzyme and phenolase of the pulp, which reduces the pectin Decomposition and enzymatic browning. The whole production process tries to isolate the air and avoid high temperature and long-term treatment. The prepared mango pulp has high viscosity, good stability, bright yellow color and strong aroma.

[0026] During the mango production season, fresh mangoes can be directly mixed with other raw and auxiliary materials such as passion...

Embodiment 1

[0037] Take 100kg of purple flower mangoes that have been ripened to full ripeness, and beat with a double-channel beater after cleaning and screening. Add nozzle at the mango pulp outlet of beater, spray 10% (by weight percentage) citric acid solution 50g by here. The fruit pulp obtained from the beater is transported into the tubular heat exchanger through the screw pump, heated to 85°C within 30s, then kept at a constant temperature for 120s, and rapidly cooled to 40°C, the whole time is 200s. After the above treatment, 59.2 kg of mango pulp was obtained, with a pH of 3.5, a golden color and a rich aroma. The obtained mango pulp is compounded with 100% pineapple juice (reduced with pineapple concentrated juice), passion fruit puree, sugar and purified water, and then obtained through homogenization, sterilization and hot filling to obtain PET bottled mango compound fruit juice. The beverage has a shelf life of up to 6 months, and there is no obvious stratification during ...

Embodiment 2

[0044] Get Tainong No. 1 mango 100kg, produce mango pulp by the method of embodiment 1, spray 500g of 10% citric acid solution, through 95 ℃, 15s inactivate enzyme, obtain 54.8kg pulp, pH value 4.0. The pulp is homogenized, pasteurized and filled aseptically to obtain 53.9kg mango puree. After blending the mango puree with other fruit juices, the Tetra Pak mango compound juice drink can be obtained through homogenization, sterilization and aseptic filling. After 6 months of storage and transportation, there is a small amount of precipitation at the bottom of the box, but the product has no obvious layering, and the color is yellow and uniform.

[0045] The compound formula is: mango puree 40kg

[0046] 100% orange juice (reduced from orange juice concentrate) 8kg

[0047] Passion fruit puree 10kg

[0048] Sugar 5kg

[0049] Purified water 37kg

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com