High-performance semiconductor nanometer silicon field electronic emission material and its preparation method

A field electron emission and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, nanostructure manufacturing, nanotechnology, etc., can solve the problems of large open electric field and low field emission current density, so as to improve the electric field intensity and facilitate large-scale production , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

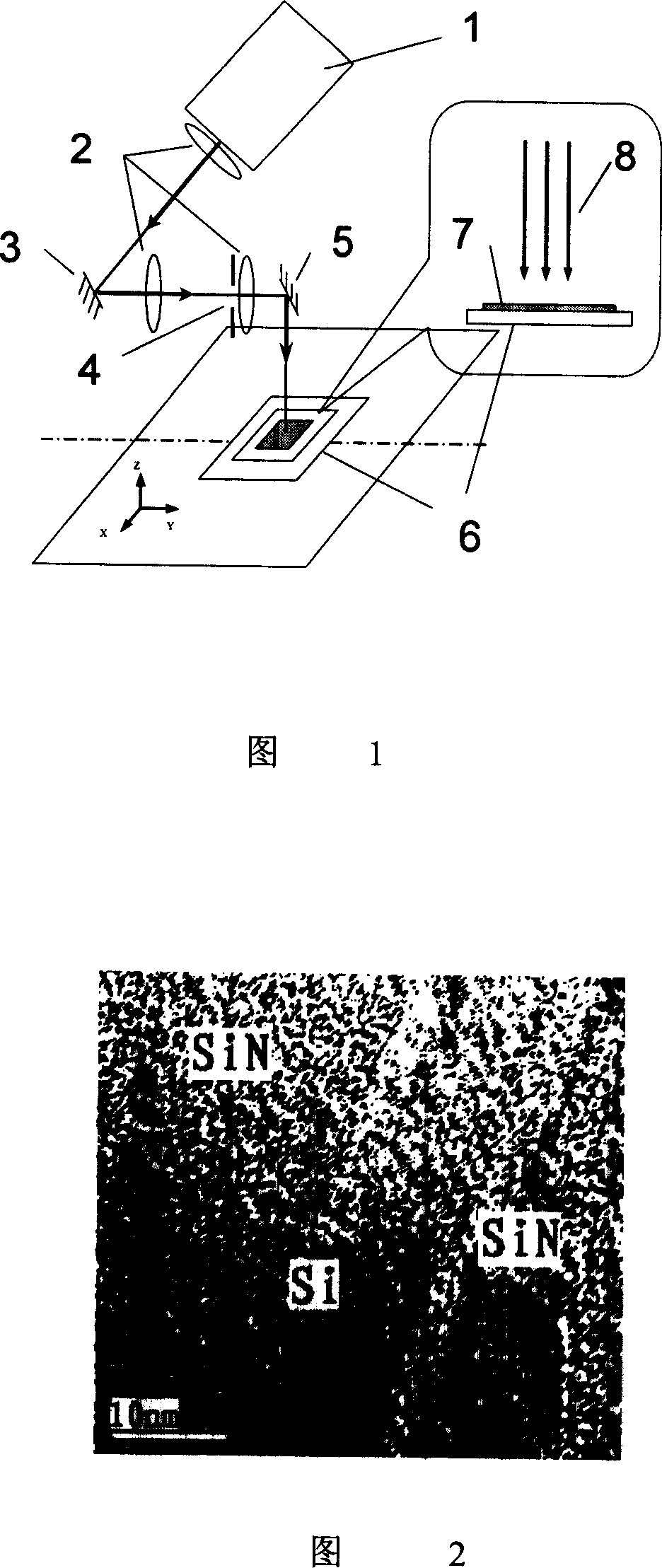

[0035] This embodiment adopts the following process to prepare high-performance semiconductor silicon field electron emission material:

[0036] 1. Preparation of hydrogenated amorphous silicon (a-Si:H) thin film: use flat capacitive radio frequency plasma enhanced chemical vapor deposition (PECVD) system (for example: Plasmalab system100 of Oxford Instrument Company, China, Shenyang Science and Instrument Center of Chinese Academy of Sciences in China PECVD-X equipment is on the stage, usually the power source frequency is 13.56MHz, and the power is 30W) to deposit hydrogenated amorphous silicon semiconductor film on the substrate.

[0037] The film can be deposited on a heavily doped n-type Si (100) substrate covered with an amorphous silicon nitride film, or on a glass substrate or other substrates evaporated with a metal film.

[0038] During deposition, the substrate is placed on the grounded anode electrode of the reaction chamber, and the reaction gas is silane (SiH 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com