Decompression drying processing device

A drying treatment and mounting technology, applied in the direction of pretreatment of surface, drying of solid materials, drying of solid materials without heating, etc., can solve the problems of heavier top plate weight, foreign matter on the coating film surface, and mechanical hand interference, etc., to prevent interference. , The effect of preventing foreign matter on the surface and prolonging the exhaust time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

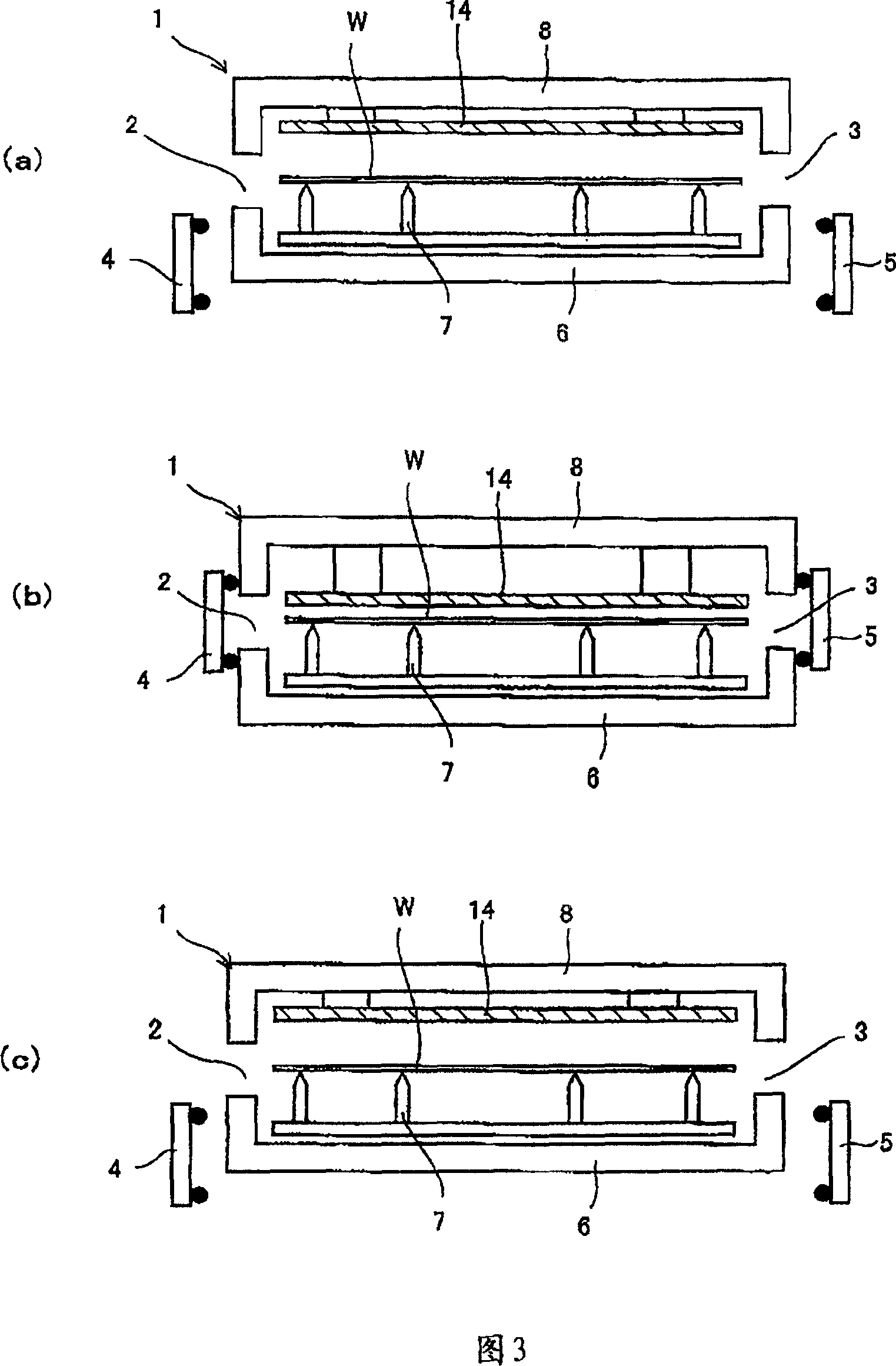

[0021] Embodiments of the present invention will be described below with reference to the accompanying drawings.

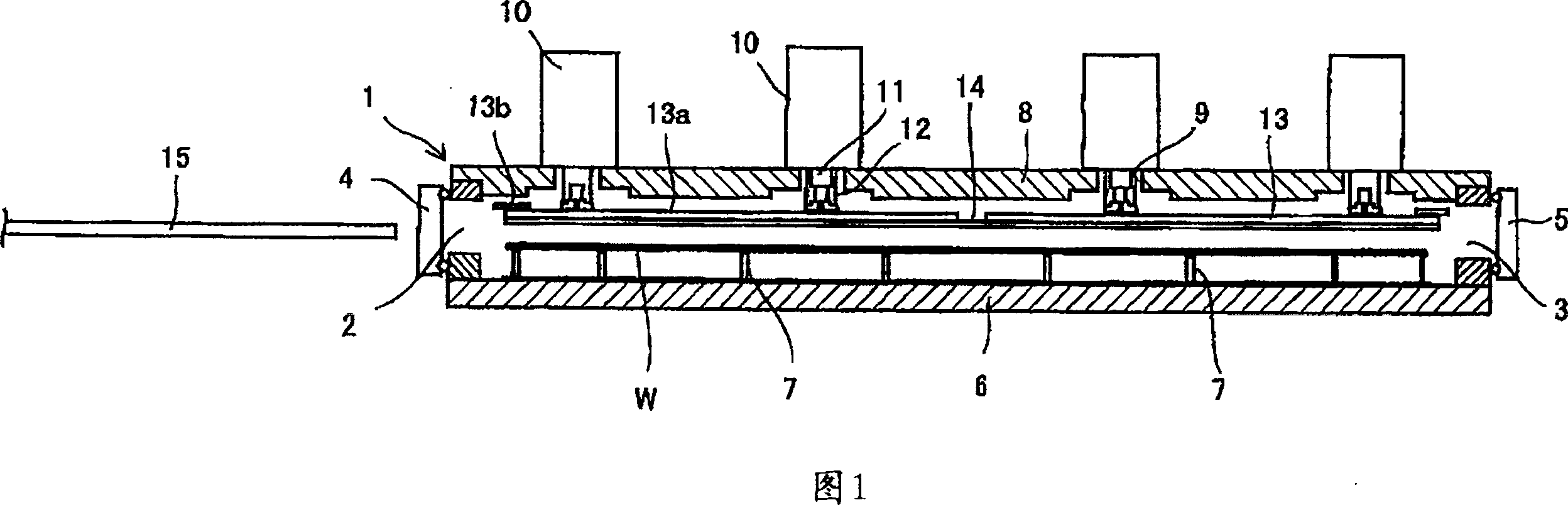

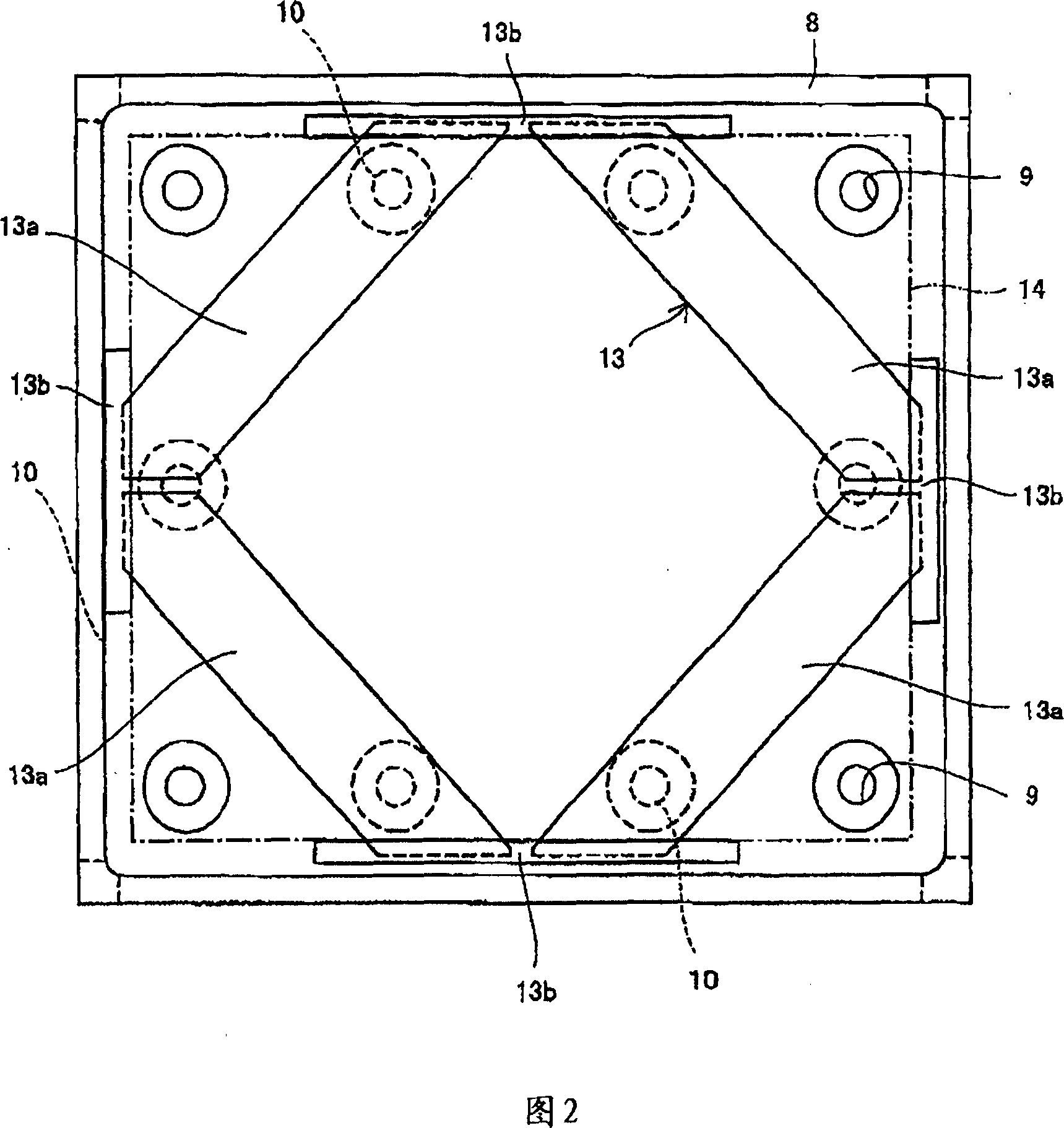

[0022] Fig. 1 is a cross-sectional view of a vacuum drying treatment device according to the present invention, and Fig. 2 is a view taken along the direction A-A of Fig. 1 .

[0023] In the reduced-pressure drying processing apparatus, an opening 2 for carrying in a substrate is formed on one side wall of a flat box-shaped chamber 1, and an opening 2 for carrying out a substrate is formed on the other side wall. Opening 3, and openings 2, 3 are opened and closed by doors 4, 5. These doors 4 and 5 are configured to be able to be opened and closed by a driving device not shown in the figure.

[0024] A support rod 7 (mounting member) for supporting the substrate W is provided on the bottom 6 of the chamber 1, and a plurality of (12 in the illustrated example) openings 9 for vacuuming are formed on the top 8 of the chamber 1. Cylinder units 10 as a lifting device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com