Film-shell type multiple-effect film-reducing distillation sea-water desalinating device

A technology of falling film distillation and multi-effect distillation, which is applied in seawater treatment, energy waste water treatment, general water supply conservation, etc., can solve the problems of high cost of seawater desalination equipment, difficult water production cost, and competition of large-scale equipment, and achieves simplified seawater pretreatment. Treatment process, the effect of reducing the cost of fresh water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

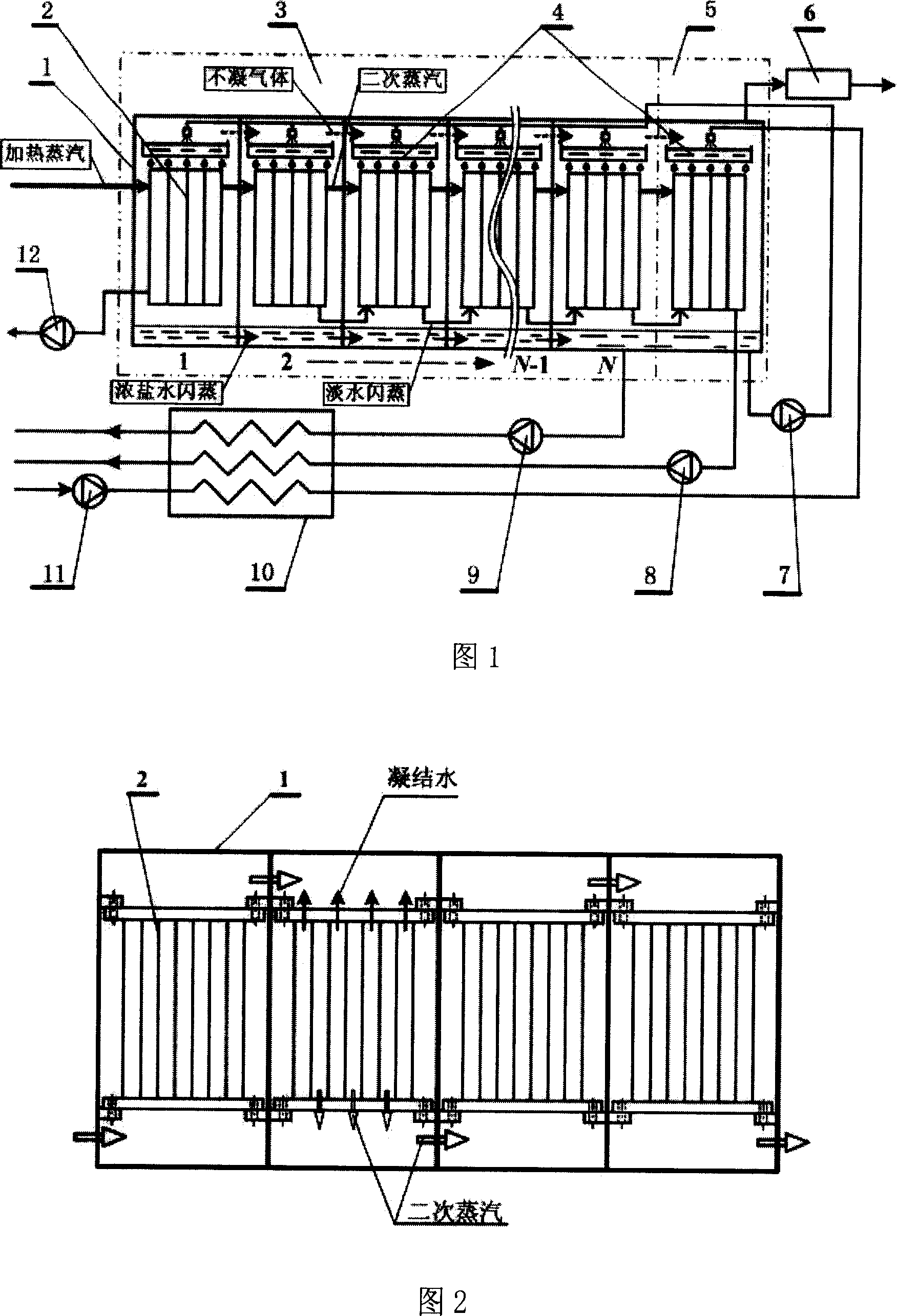

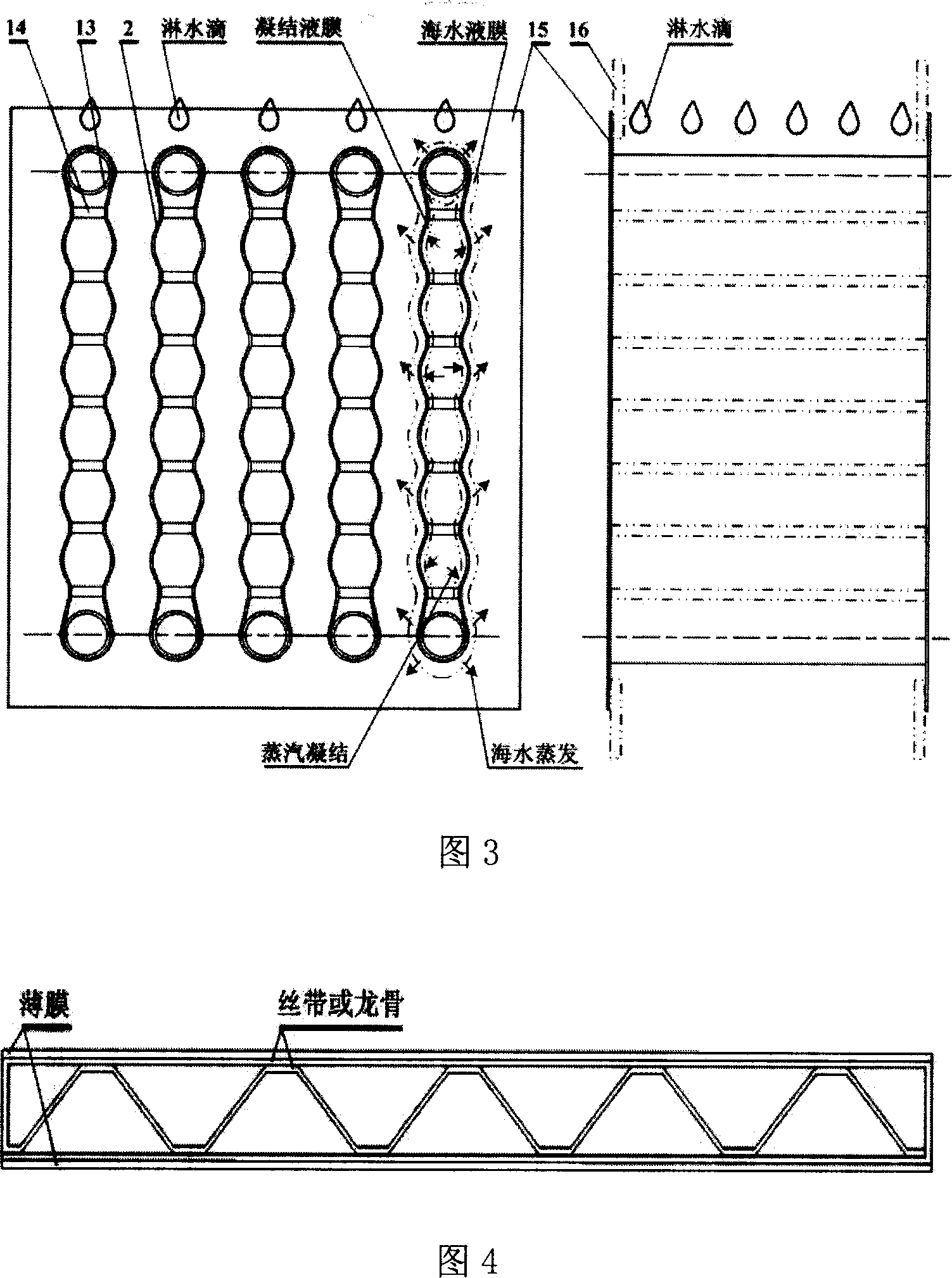

[0023] The invention provides an energy-saving, environment-friendly, low-cost, safe and reliable membrane shell type multi-effect falling film distillation seawater desalination device urgently needed by the market. In the flow chart of the membrane shell multi-effect distillation seawater desalination device shown in Figure 1, the device uses plastic film as a heat exchange material to replace the traditional metal heat exchange material. The thickness of the plastic film is 50 to 250 μm, and the thickness is less than 0.5mm. sheet.

[0024] In Figure 1, N relatively independent containers are set in the housing 1, and N membrane bundle assemblies 2 are respectively installed in the independent containers, and then the evaporator 3 is formed in series, and is connected in series with the condenser 5, and the membrane bundle assemblies 2 are separated Placed in the container unit from the first effect to the N-1th effect in the shell 1, the membrane bundle assembly 2 of the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com