Desulfurization wastewater zero-discharge treatment system and method

A technology for desulfurization wastewater and treatment system, which is applied in gaseous discharge wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc. It can solve the problems of high operating cost, many nodes, and large investment, and reduce the floor space. and equipment investment, reducing process energy consumption, and simplifying the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

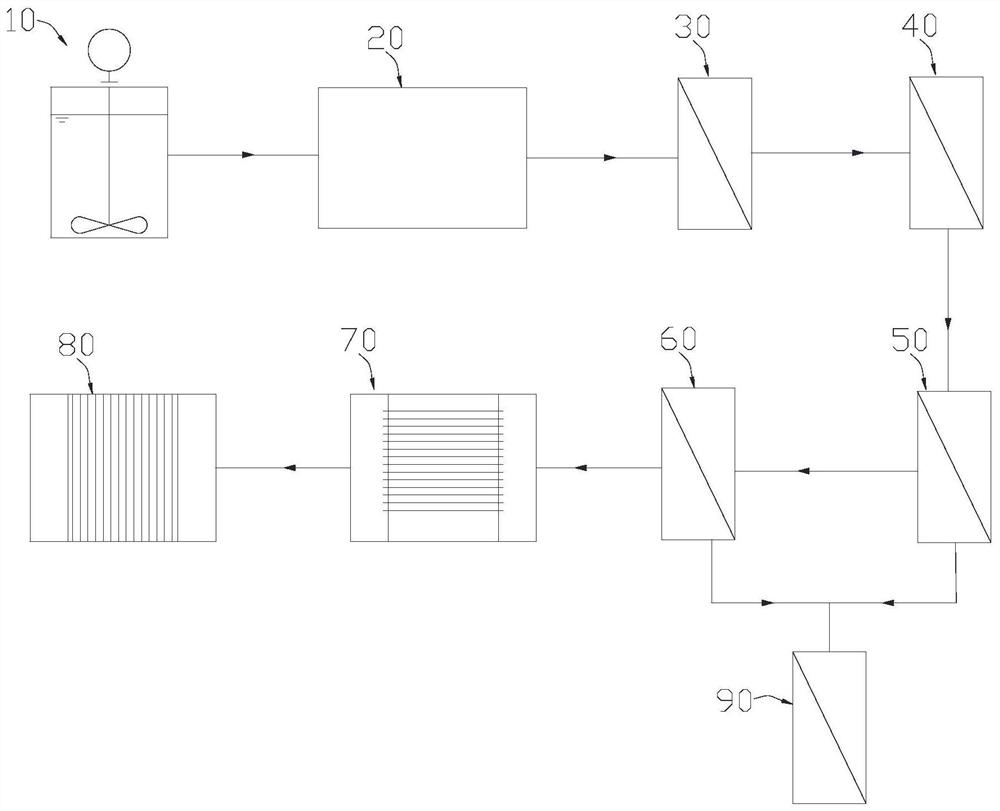

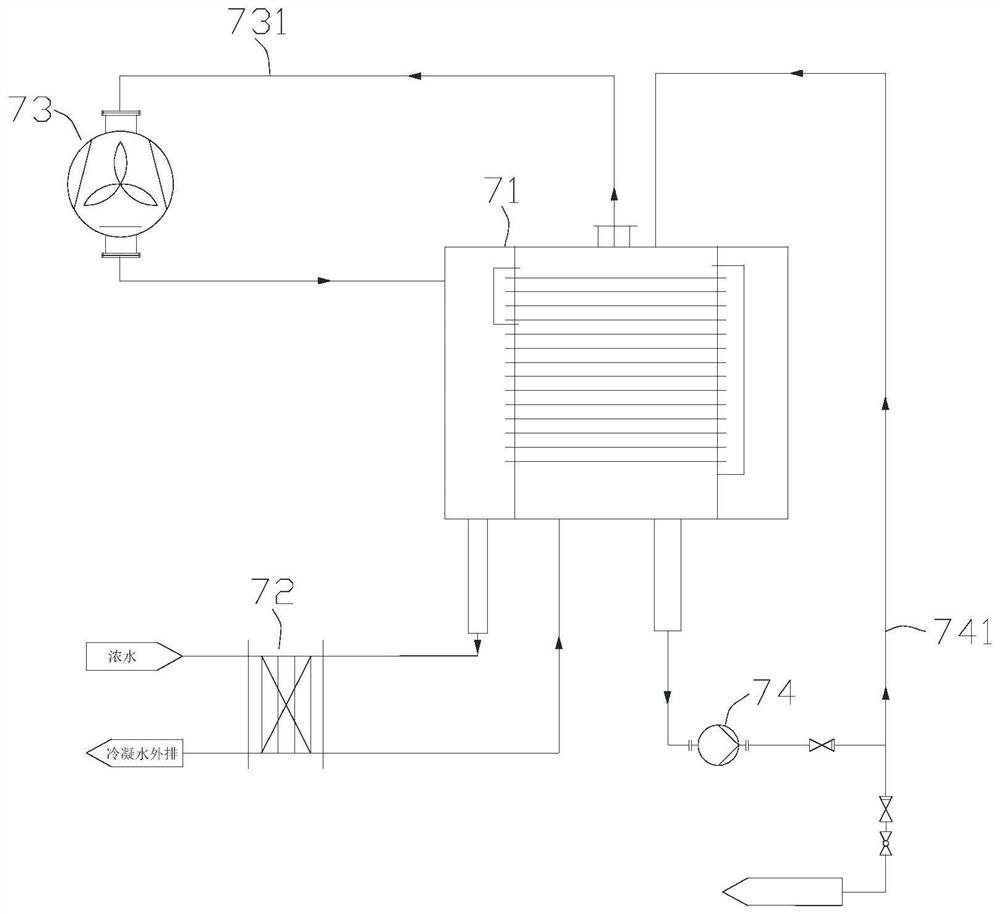

[0038] Such as figure 1 As shown, the zero-discharge treatment system for desulfurization wastewater according to an embodiment of the present invention includes a regulating tank 10, an integrated pretreatment device 20, a microfiltration device 30, a nanofiltration device 30, Filtration device 40, high-pressure reverse osmosis device 50, ultra-high pressure reverse osmosis device 60, horizontal tube falling film concentration device 70, and evaporation crystallization device 80.

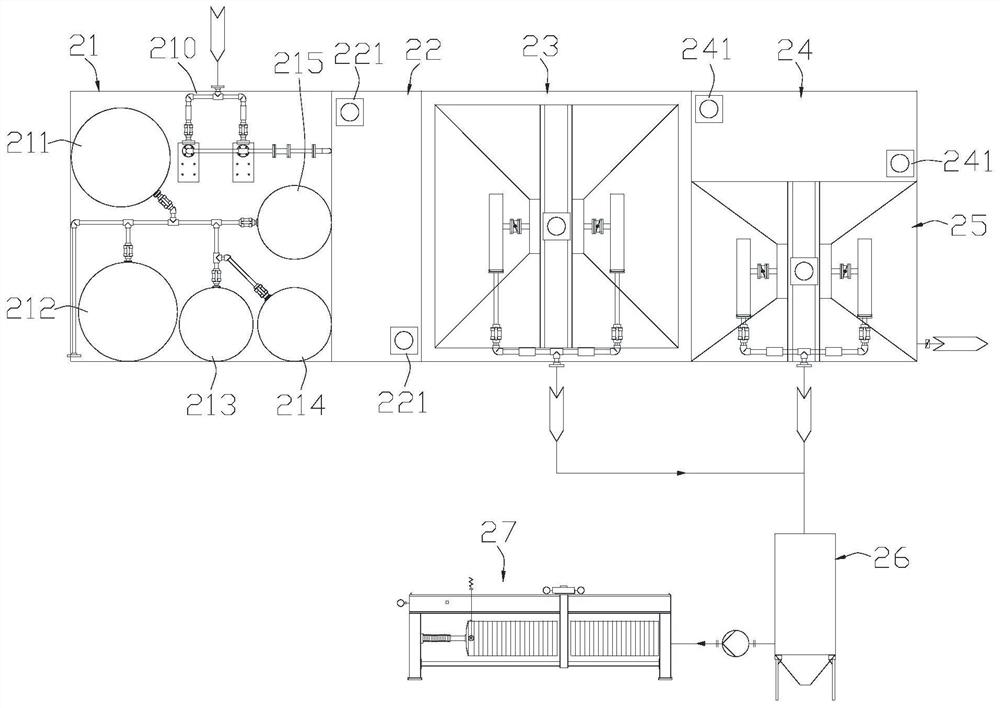

[0039] Wherein, the regulating pool 10 is connected to the desulfurization wastewater, and the desulfurization wastewater can be stirred to make the desulfurization wastewater uniform in solid and liquid and not easy to settle. The integrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com