Inner-cooling combination cutter

A technology of reamer and internal cooling, applied in the direction of reamer, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problem of heat not being discharged in time, affecting the quality of hole processing, and unstable hole size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

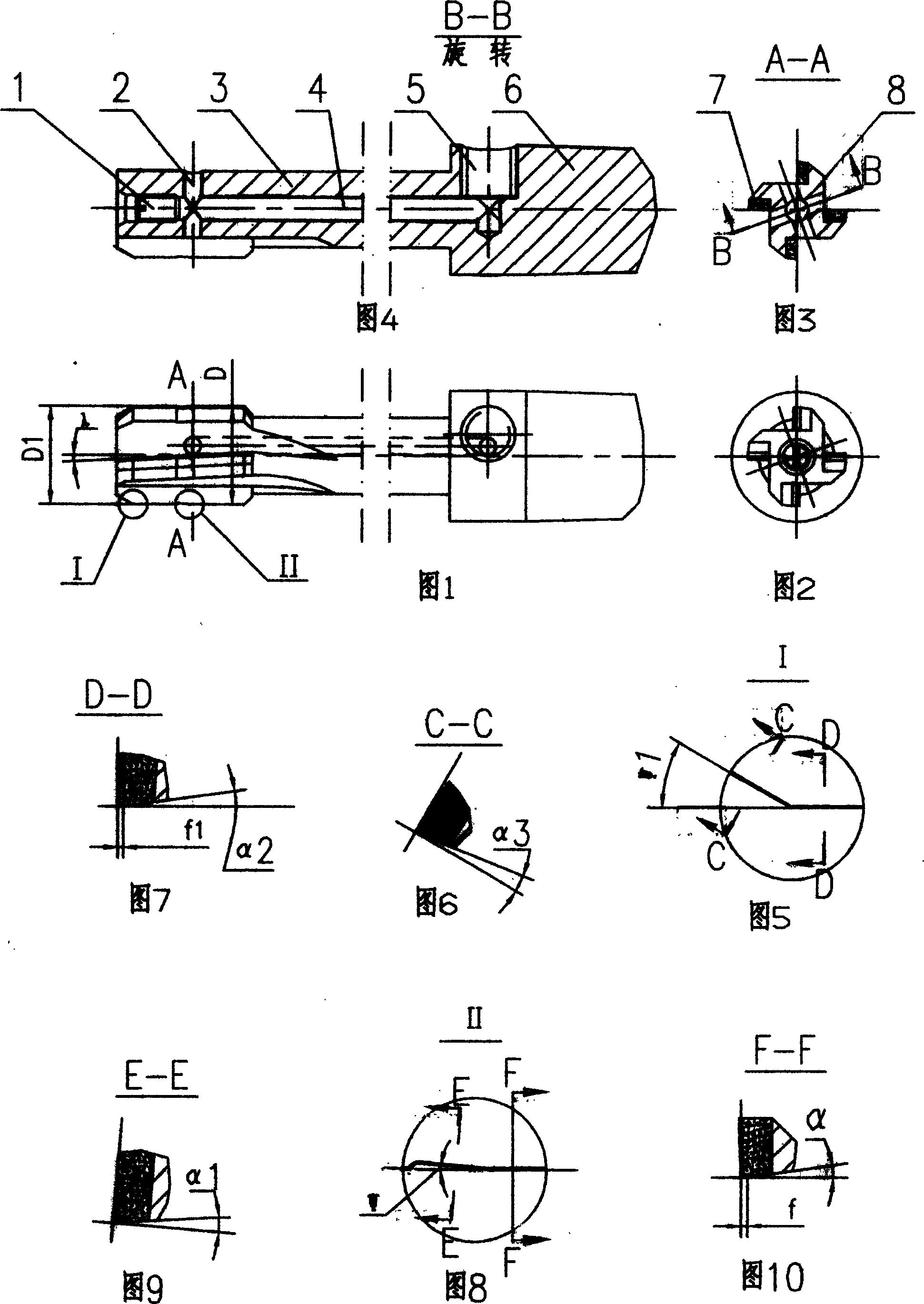

[0010] Referring to the accompanying drawings, the structure of the internal cooling compound reamer is as follows: the cemented carbide blade 7 is welded on the cutter tooth 8, the radially arranged water inlet hole 5 is at the front end of the handle 6, and the handle 6 has a central hole at the rear end. Commonly used Morse tool cones. The radially arranged water outlet hole 2 is at the bottom of each knife tooth groove. Due to technological requirements, the water hole 4 in the core of the cutter bar 3 is drilled from the front end of the reamer to connect the water inlet hole 5 and the water outlet hole 2, and the screw plug Installed in the threaded hole at the front end of the water hole 4, the water hole 4 orifice has a 60-degree conical hole, in order to be used as a positioning reference when the reamer is processed together with the center hole at the rear end of the handle 6; the water inlet 5 is Threaded hole, the cutting fluid enters directly from this hole, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com