Optimized liquid-phase oxidation

An oxidation reactor and xylene technology, applied in the direction of preparation of organic compounds, organic chemistry, chemical instruments and methods, etc., can solve expensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

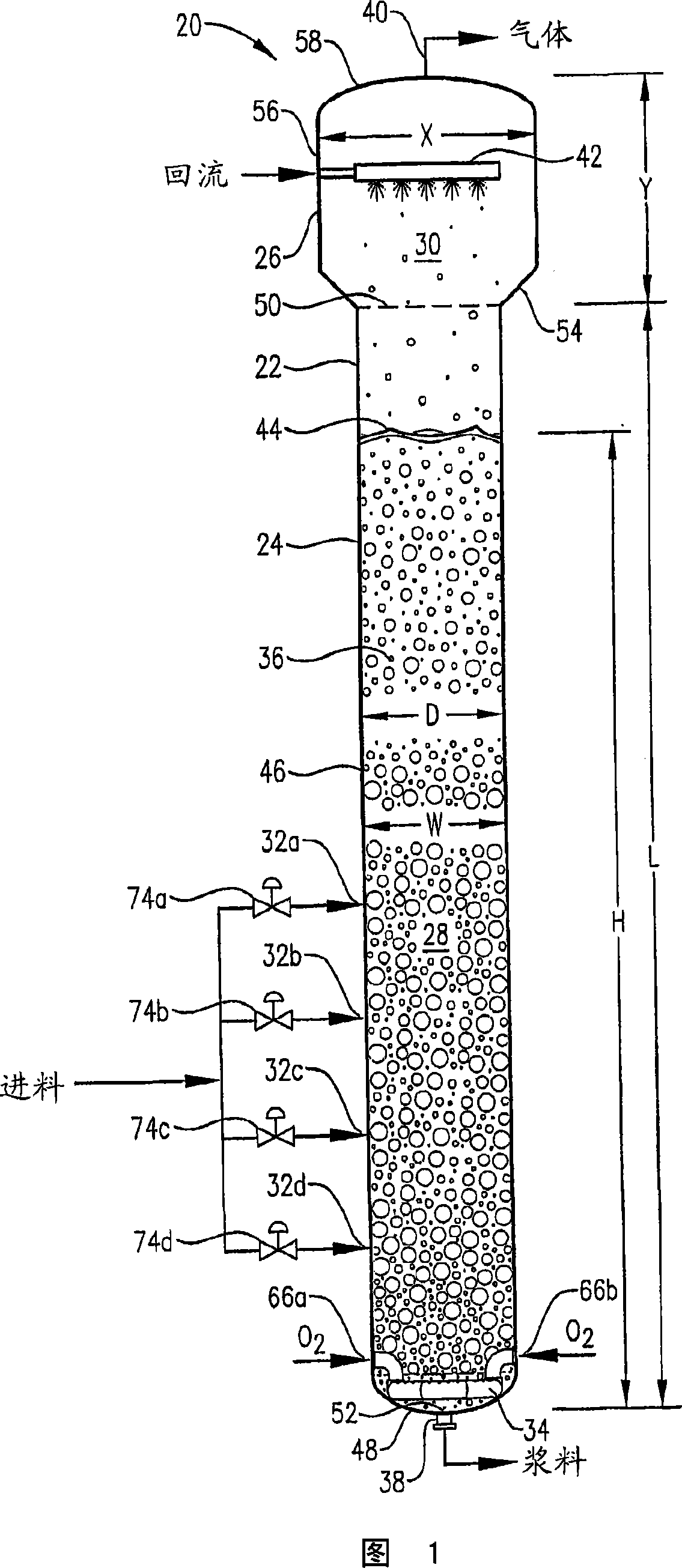

[0294] Examples 1-4 relate to the formation of terephthalic acid through the pilot scale oxidation of p-xylene in a pilot scale system assembled in a mechanically agitated 2 gallon tank with a hot oil jacket. Around the titanium reaction vessel. The gas dispersive stirrer in the reaction vessel was rotated at about 1500 revolutions per minute (rpm), and the power draw of the stirrer was about 220 watts. The pilot scale system is equipped with means to control the pressure and temperature within the reaction vessel and means to control the gas and liquid flow rates into the reaction vessel. The para-xylene feed was provided via a syringe pump at an effective steady state rate of approximately 0.28 kg / hr. The catalyst feed solution was pumped from the catalyst feed tank to the reaction vessel at an effective steady state rate of approximately 3.2 kg / hour. Both the para-xylene and the catalyst feed solution were released into the reaction medium through a dip tube whose end was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com