Asphalt-based coating compositions and salt surfactants

A technology of surfactant and composition, applied in the field of asphalt-based coating composition, can solve problems such as viscosity loss and failure, and achieve the effect of low cost and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0101] Preparation of Exemplary Compositions

[0102] The preparation of the coating compositions of the present invention will vary somewhat depending on the particular components used in the composition, the type of mixing equipment available for handling the components and the intended use. These process steps are not critical, and some of the blending procedures described herein are preferred, although they may vary considerably.

[0103] A representative propoxylated alcohol based ether amine precursor for the salt shown in formula II is from C 12 -C 15 Monoamines derived from propylene oxide adducts of alcohols. In methods well known to those skilled in the art, C 12 -C 15 Alcohol reacts with propylene oxide. The hydroxyl group of the alcohol reacts with propylene oxide to form the monoether of propylene oxide. Addition of 2-4 moles of propylene oxide per mole of alcohol produces di-, tri- and poly(propylene glycol) ethers. During the subsequent cyanoethylation, t...

Embodiment 1-6

[0116] Embodiment 1-6-basic formula

[0117] Examples 1-6 describe exemplary asphalt-based roof coating compositions. Examples 1-6 all included unoxidized pitch, palygorskite clay, and a propoxylated alcohol based ether amine salt surfactant. Other components are not included.

[0118] Examples 1-4 include comparative industry standard roof coating compositions based on Tomah Products PA-14 acetate surfactant. This industry standard roof coating composition includes unoxidized Henry Company cutback bitumen, Minugul G-35 palygorskite clay, and Tomah Products PA-14 acetate surfactant (isodecyloxypropylamine acetate surfactant) . Industry standard compositions are provided in said Examples 1-4 at C / S ratios of 8:1 and 12:1.

[0119] Each asphalt-based coating composition and standard composition was prepared using the low shear blending technique described above. In each example, 350 g samples were prepared as described in Table 1 at clay / surfactant ratios of 8:1, 12:1 and...

Embodiment 1

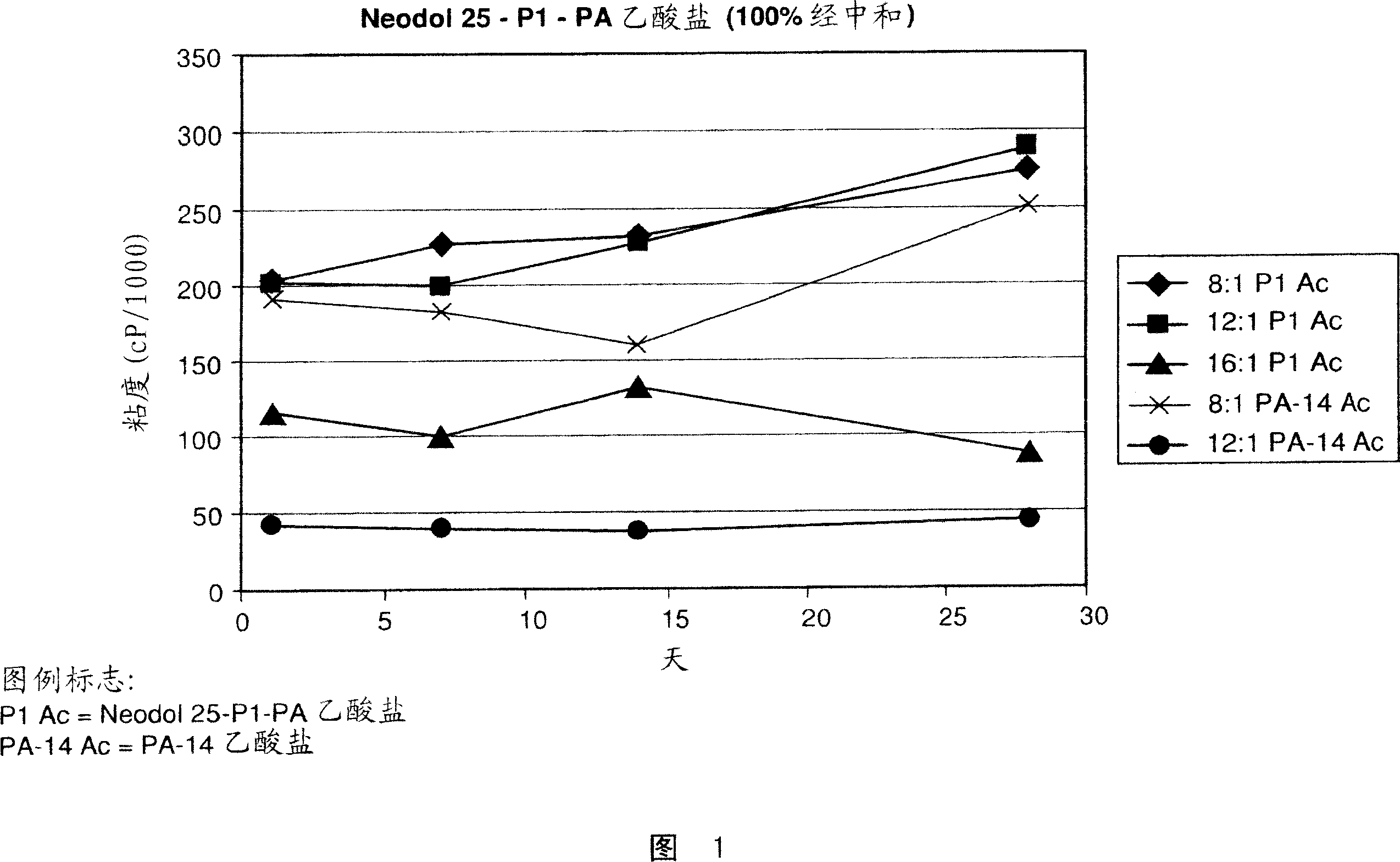

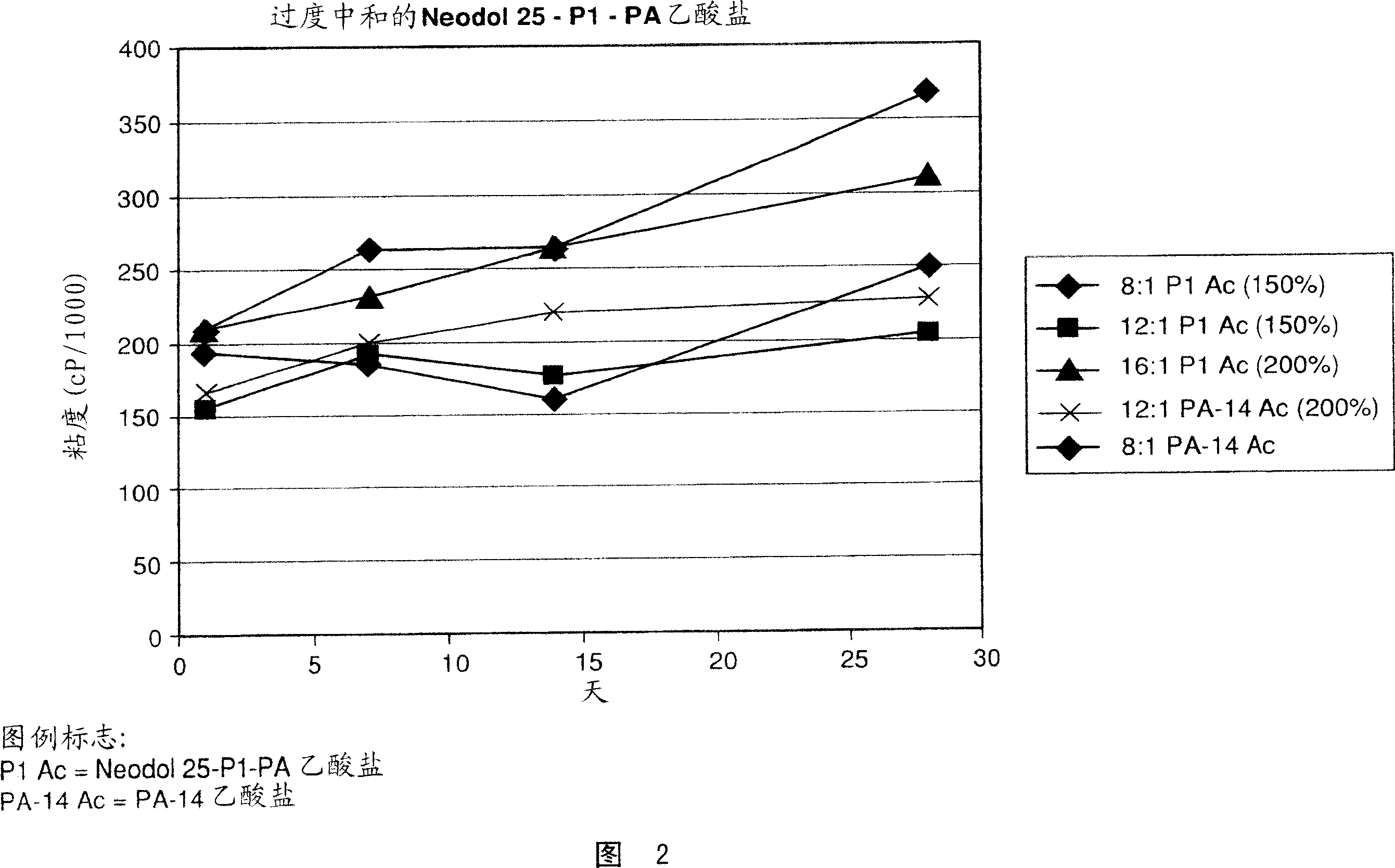

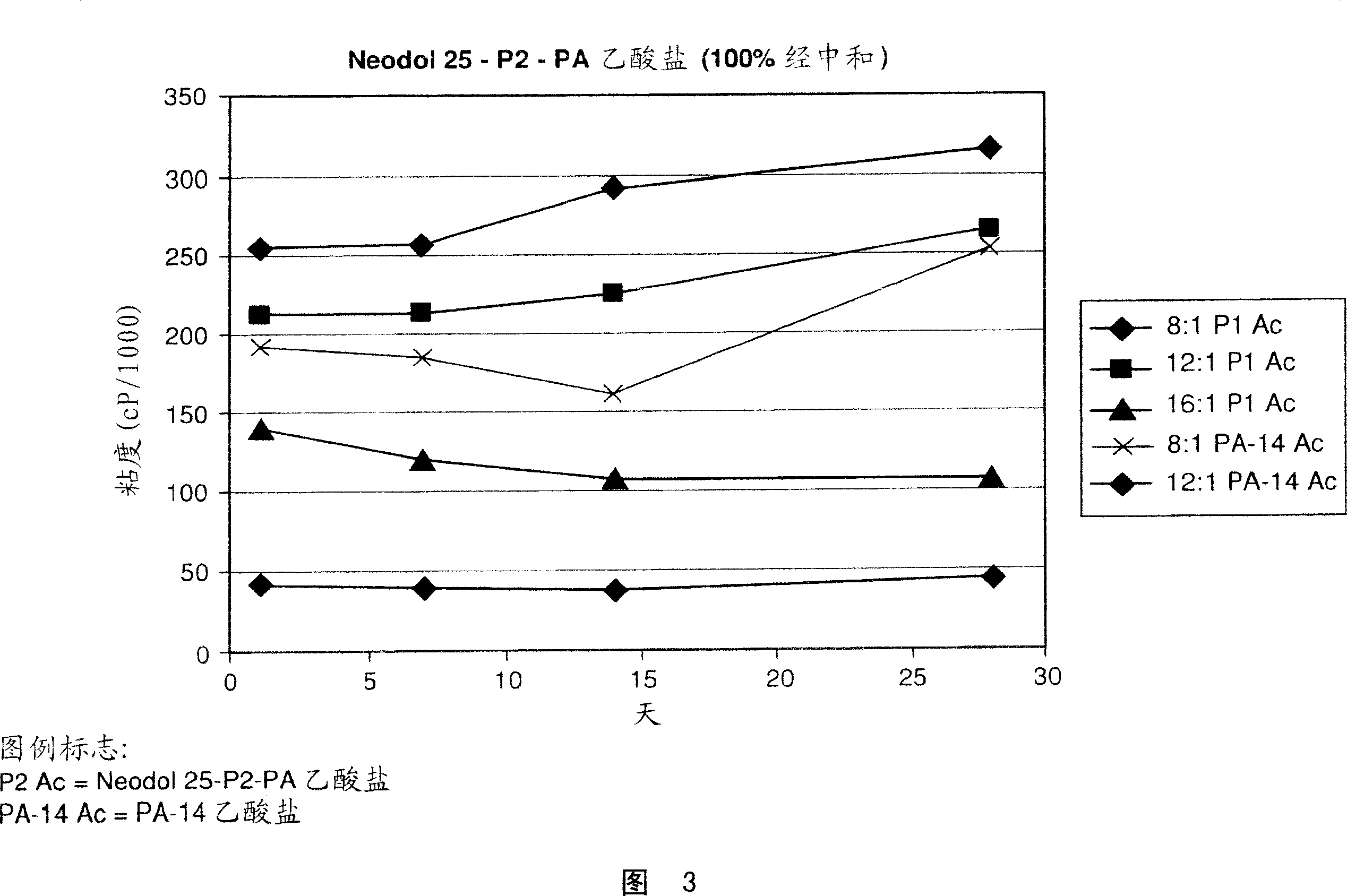

[0129] Example 1 included three asphalt-based roof coating compositions. The roof coating composition of Example 1 included unoxidized bitumen, palygorskite clay, and Neodol 25 alcohol-based 25-P1-PA acetate surfactant component. Neodol 25-P1-PA is a propoxylated alcohol-based etheramine according to formula II. Neodol 25-P1-PA in R 1 The position contains the distribution of carbon atoms. R 1 is an aliphatic group having about 12 to 15 carbon atoms, m is 1 and R 2 For n-propyl. Neodol 25-P1-PA was completely neutralized (ie about 100% neutralization) with about 1 molar equivalent of acetic acid. A roof coating composition comprising the industry standard PA-14 acetate surfactant was included, thereby providing a basis for comparison.

[0130] Table 3 provides viscosity data 4 weeks after preparation. Figure 1 graphically presents the viscosity data for each example over a four week period. The data are given in centipoise (cP) units.

[0131] table 3

[0132] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com