Preparation method of nanometer copper-silver bimetallic composite powder

A bi-metal and nano-copper technology is applied in the field of preparation of nano-copper-silver bi-metal composite powder, which can solve the problems of inability to form alloys, inability to see copper characteristic diffraction peaks, etc., so as to prevent waste and loss, improve the utilization rate of raw materials, Avoid the effect of uneven product texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

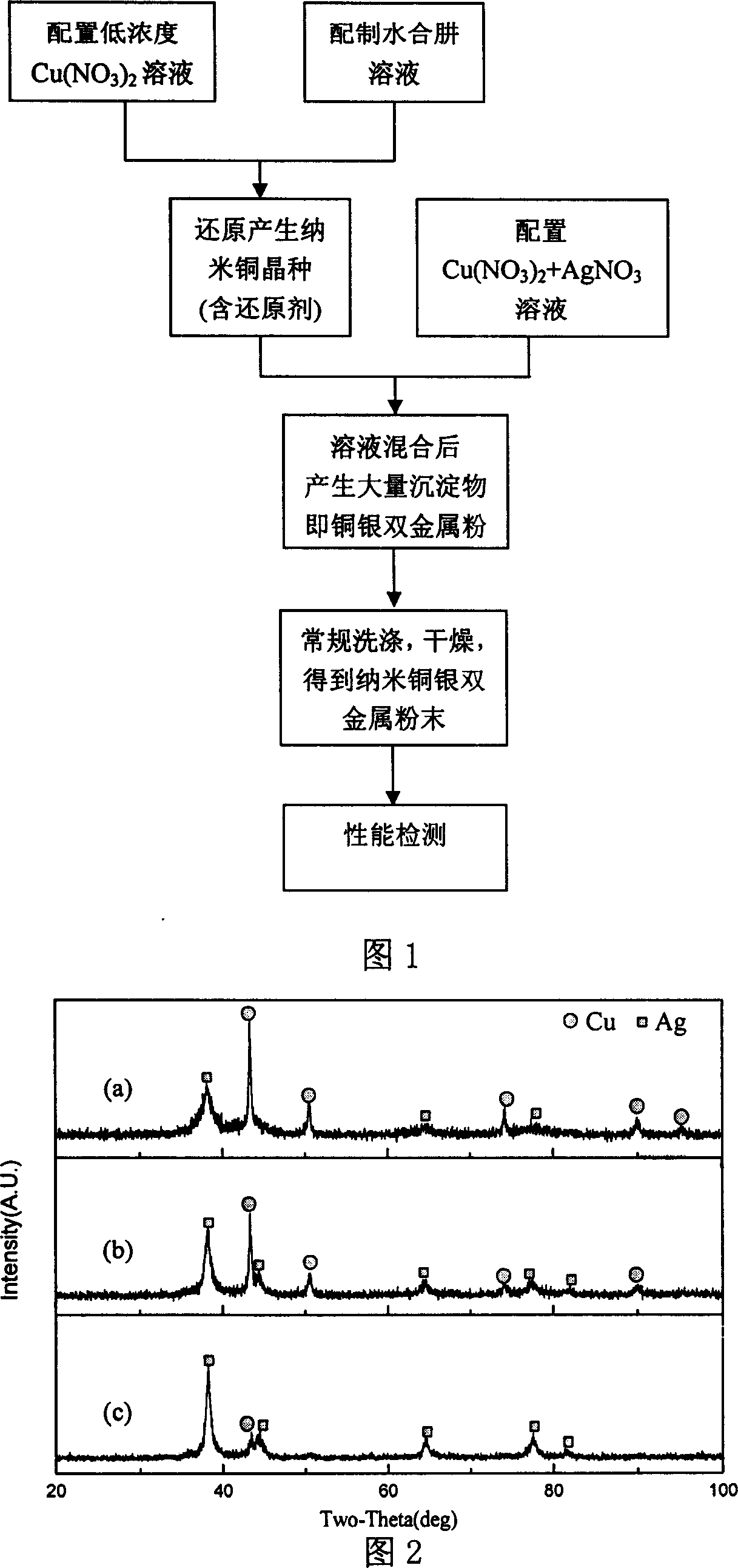

Method used

Image

Examples

Embodiment 1

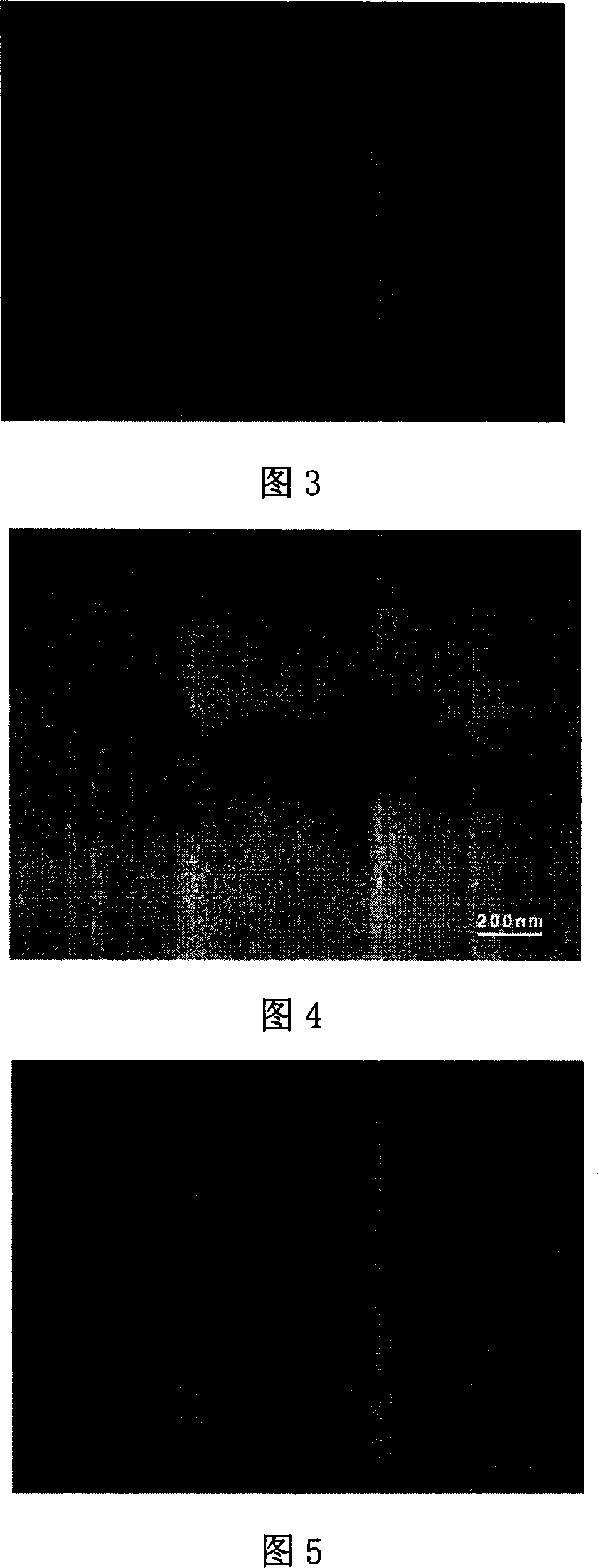

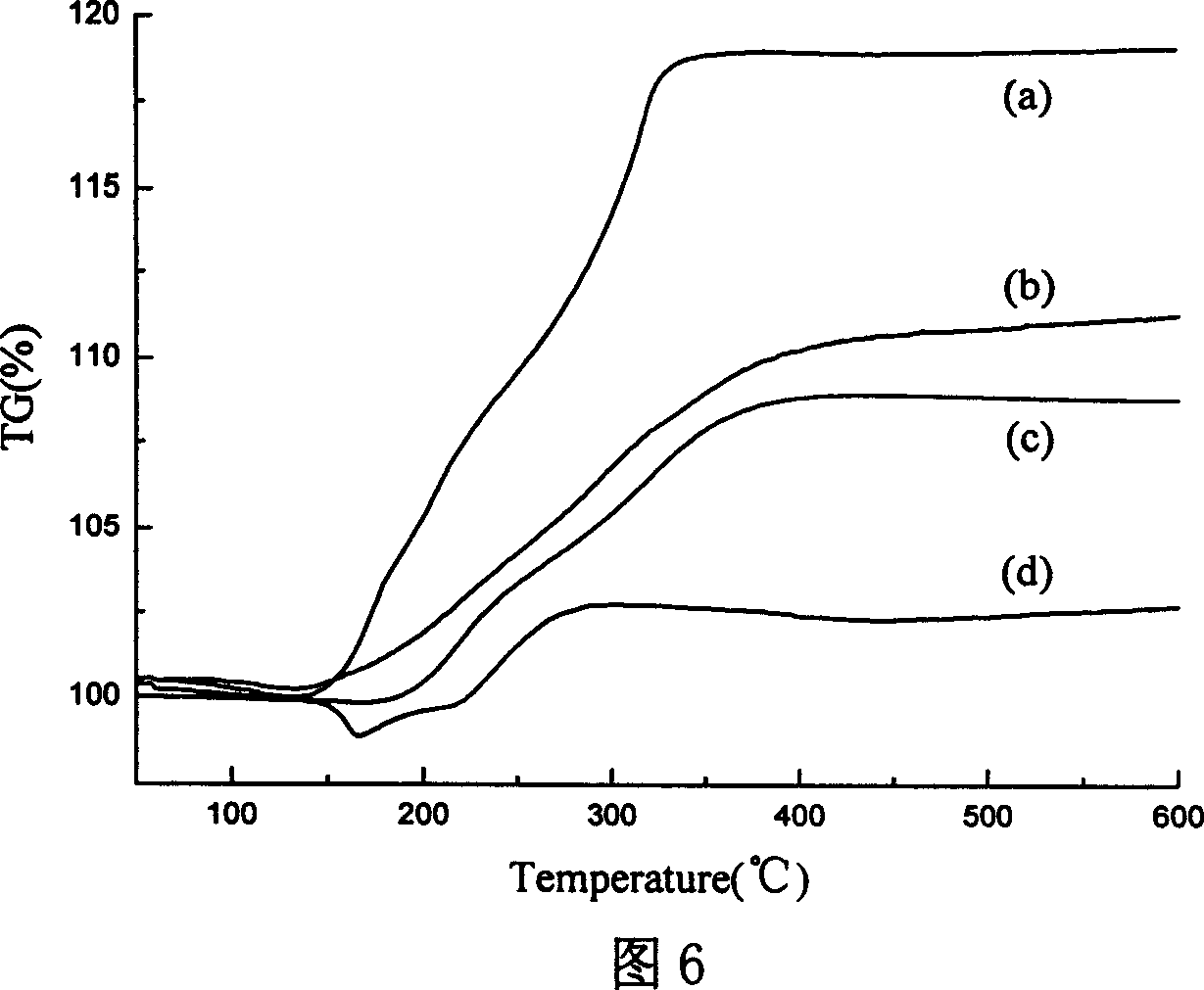

[0027] Weigh 0.24g solid Cu(NO 3 ) 2 ·3H 2 O, dissolved in 100ml of water to make an aqueous solution with a concentration of 0.01M. Then add a certain amount of ammonia water, the solution starts to become cloudy, stop adding ammonia water after the solution becomes clear again. Weigh 8.4g Cu(NO 3 ) 2 ·3H 2 Dissolve O in 100ml of water to make an aqueous solution with a concentration of 0.35M, and weigh 1.19g of AgNO at the same time 3 Dissolve in 50ml of water to make an aqueous solution with a concentration of 0.14M, then mix the two solutions to make 150ml of Cu(NO 3 ) 2 +AgNO 3 The mixed solution has a Cu / Ag molar ratio of 5:1. Measure 10ml of hydrazine hydrate and mix with 90ml of water, the volume concentration is 10%. Mix the prepared cuproammonia solution and hydrazine hydrate solution under strong stirring, keep warm in a water bath at 50°C, the solution turns reddish brown rapidly, keep warm, and stir for 10 minutes. The prepared Cu(NO 3 ) 2 +AgNO 3 Th...

Embodiment 2

[0029] Weigh 0.24g solid Cu(NO 3 ) 2 ·3H 2 O, dissolved in 100ml of water to make an aqueous solution with a concentration of 0.01M. Then add a certain amount of ammonia water, the solution starts to become cloudy, stop adding ammonia water after the solution becomes clear again. Weigh 4.8g Cu(NO 3 ) 2 ·3H 2 Dissolve O in 100ml of water to make an aqueous solution with a concentration of 0.2M, and weigh 1.7g of AgNO at the same time 3 Dissolve in 50ml of water to make an aqueous solution with a concentration of 0.2M, and then mix the two solutions to make 150ml of Cu(NO 3 ) 2 +AgNO 3 The mixed solution has a Cu / Ag molar ratio of 2:1. Measure 10ml of hydrazine hydrate and mix with 90ml of water, the volume concentration is 10%. Other steps are with embodiment 1. The prepared copper-silver bimetallic composite powder was analyzed by XRD (see Figure 2(b)), TEM (see Figure 4) and TG (see Figure 6(c)).

Embodiment 3

[0031] Weigh 0.24g solid Cu(NO 3 ) 2 ·3H 2 O, dissolved in 100ml of water to make an aqueous solution with a concentration of 0.01M. Then add a certain amount of ammonia water to start the solution to become turbid, and stop adding ammonia water after the solution becomes clear again. Weigh 0.96g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 25ml of water to prepare an aqueous solution with a concentration of 0.16M, and at the same time weighed 4.25g of AgNO 3 Dissolve in 75ml of water to make an aqueous solution with a concentration of 0.33M, then mix the two solutions to make 100ml of Cu(NO 3 ) 2 +AgNO 3The mixed solution has a Cu / Ag molar ratio of 1:5. Measure 10ml of hydrazine hydrate and mix with 90ml of water, the volume concentration is 10%. Other steps are with embodiment 1. The prepared copper-silver bimetal composite powder was analyzed by XRD (see Figure 2(c)), TEM (see Figure 5) and TG (see Figure 6(d)).

[0032] As can be seen from Figure 2, the XRD spectrum of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short diameter | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Short diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com