Process for producing elastic fluorocopolymer and crosslinked fluororubber

A manufacturing method and a technology for copolymers, applied in the field of cross-linked fluororubber, can solve problems such as easily hindering cross-linking, and achieve the effects of good cross-linking reactivity, good compression set, and reduced phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

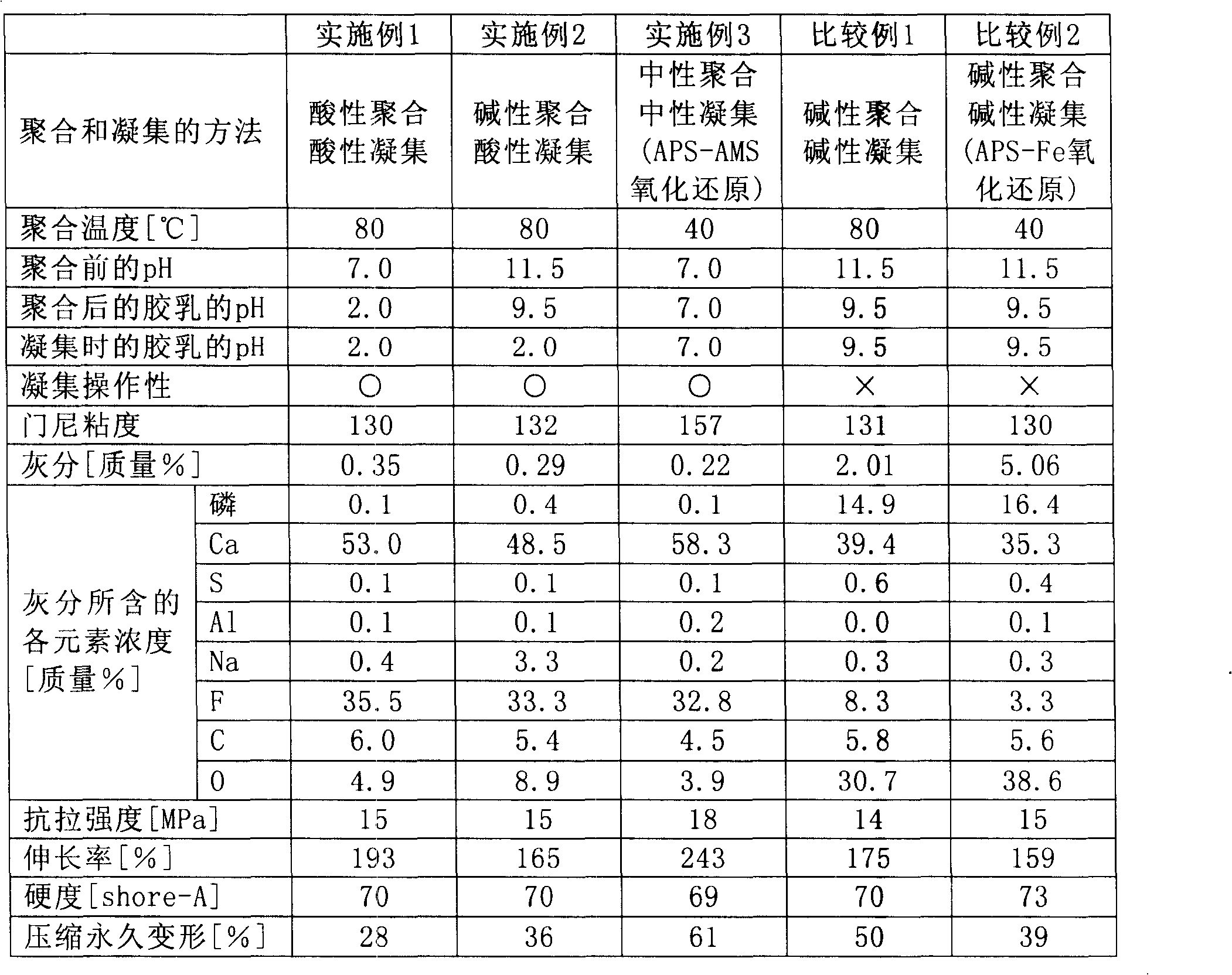

Examples

Embodiment 1

[0107] (acid polymerization - acid coagulation)

[0108] A stainless steel pressure vessel having an internal volume of 3200 mL having an anchor fin for stirring was degassed, and then a homogeneous mixed solution of 1600 g of ion-exchanged water, 97 g of tert-butanol, and 9 g of sodium lauryl sulfate was added. The pH of this homogeneous mixture was 7.0. Next, the temperature of the solution in the reactor was raised to 80° C., and the pre-prepared monomer mixed gas of TFE / P=85 / 15 (molar ratio) was injected to make the internal pressure of the reactor 2.50 MPaG. The fins were rotated at 300 rpm, and 25 g of a 10% by mass aqueous solution of ammonium persulfate was added to start the polymerization reaction.

[0109] The pressure decreases with the progress of polymerization, so when the internal pressure of the reactor drops to 2.49MPaG, the mixed gas of TFE / P=56 / 44 (molar ratio) prepared in advance is pressed into the internal pressure of the reactor by self-pressure, so th...

Embodiment 2

[0113] (Basic Polymerization-Acidic Coagulation)

[0114] After degassing a stainless steel pressure vessel with an inner volume of 3200 mL having anchor fins for stirring, 1600 g of ion-exchanged water, 97 g of tert-butanol, 9 g of sodium lauryl sulfate, 1.5 g of sodium hydroxide, and 42 g of sodium hydrogenphosphate were added. The pH is 11.5. Next, a monomer mixed gas of TFE / P=85 / 15 (molar ratio) was pressurized at 80° C. so that the internal pressure of the reactor was 2.50 MPaG. The fins were rotated at 300 rpm, and 25 g of a 10% by mass aqueous solution of ammonium persulfate was added to start the polymerization reaction.

[0115] Other than that, it carried out similarly to Example 1, and obtained the TFE / P / crotonate vinyl ester copolymer latex of 20 mass % of solid content concentration. The pH of the obtained latex was 9.5. The polymerization time was about 3.5 hours.

[0116] After adjusting the pH of 2205 g of the latex to 2.0 with sulfuric acid, it was added t...

Embodiment 3

[0119] (neutral aggregation-neutral agglutination)

[0120] After degassing a stainless steel pressure vessel with an inner volume of 3200 mL having anchor fins for stirring, 1600 g of ion-exchanged water, 97 g of tert-butanol, 9 g of sodium lauryl sulfate, and 8.0 g of ammonium sulfite were added. At this point the pH of the solution was 7.0. Next, a monomer mixed gas of TFE / P=85 / 15 (molar ratio) was pressurized at 40° C. so that the internal pressure of the reactor was 2.50 MPaG. The fins were rotated at 300 rpm, and a 10% by mass aqueous solution of ammonium persulfate was added to start the polymerization reaction. Then, a 10% by mass aqueous solution of ammonium persulfate was continuously added using a high-pressure pump.

[0121] The pressure decreases with the progress of polymerization, so when the internal pressure of the reactor drops to 2.49MPaG, the mixed gas of TFE / P=56 / 44 (molar ratio) prepared in advance is pressed into the internal pressure of the reactor by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com