Parallel distribution optical fibre raster temp. sensing method and its system

A distributed optical fiber and fiber grating technology, which is applied in the direction of using optical devices to transmit sensing components, thermometers, and thermometers with physical/chemical changes, can solve problems such as insufficient system reliability, small installation space, and operational complexity. , to achieve the effects of reducing product testing and maintenance costs, good consistency and interchangeability, and a large number of measurement points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

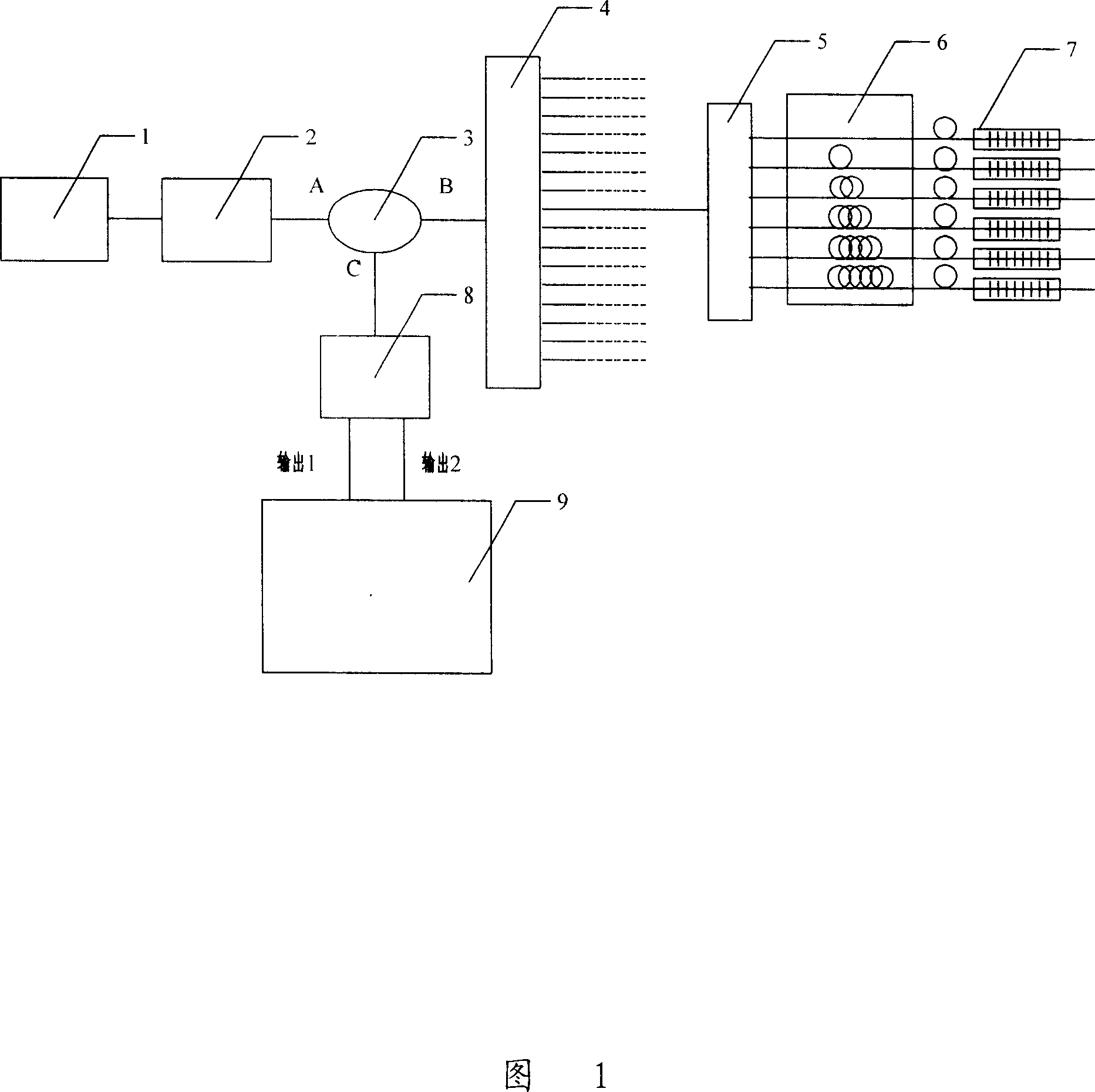

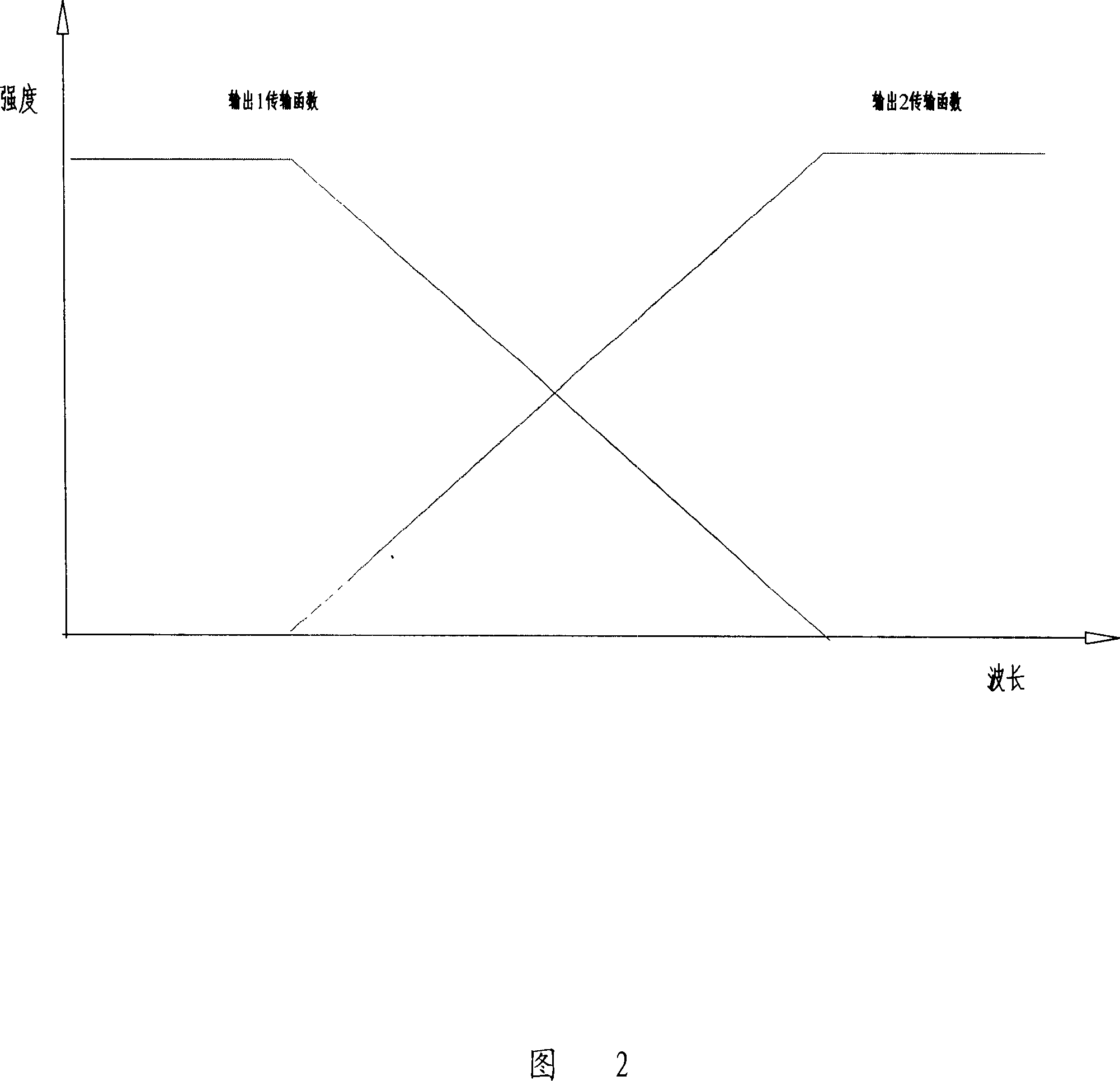

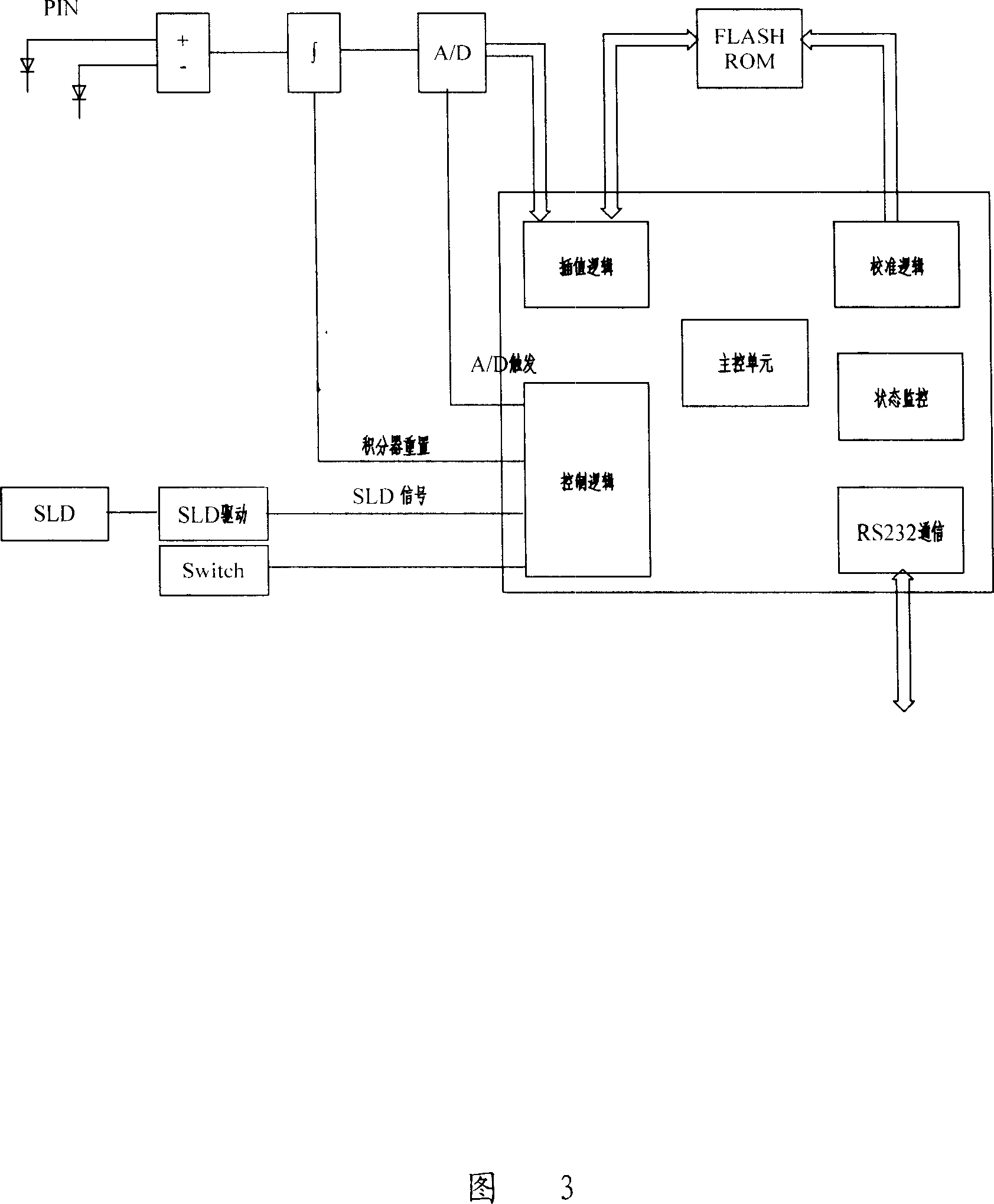

[0042] As shown in Figure 1, the SLD sends out a C-band optical signal with a spectral width of 40nm, which is amplified by the EDFA and then input to the A port of the circulator. The circulator outputs an optical signal from the B port to the common input port of the optical switch, and the optical switch switches the input signal to different Output port, each output port is connected with a fiber coupler, the fiber coupler divides the input optical signal to each output branch, and the optical signal output by each output branch is delayed by the fiber optic delay line group through the fiber grating sensor ( FBG) reflection. The FBG reflection signal passes through the fiber delay line group and then is combined by the fiber coupler, and then is input to the optical filter from the C port of the circulator after passing through the optical switch array and the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com