Furnace dephosphorus rod agent for electric furnace molten steel

A technology for internal dephosphorization rod agent and molten steel furnace, which is applied to hearth furnaces, furnaces, furnace types, etc., can solve the problems of harsh environment, dangerous operation, serious pollution, etc., and achieves the effect of simple preparation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The raw materials used in the formula of the present invention are all commercialized powdery (30-200 mesh) materials.

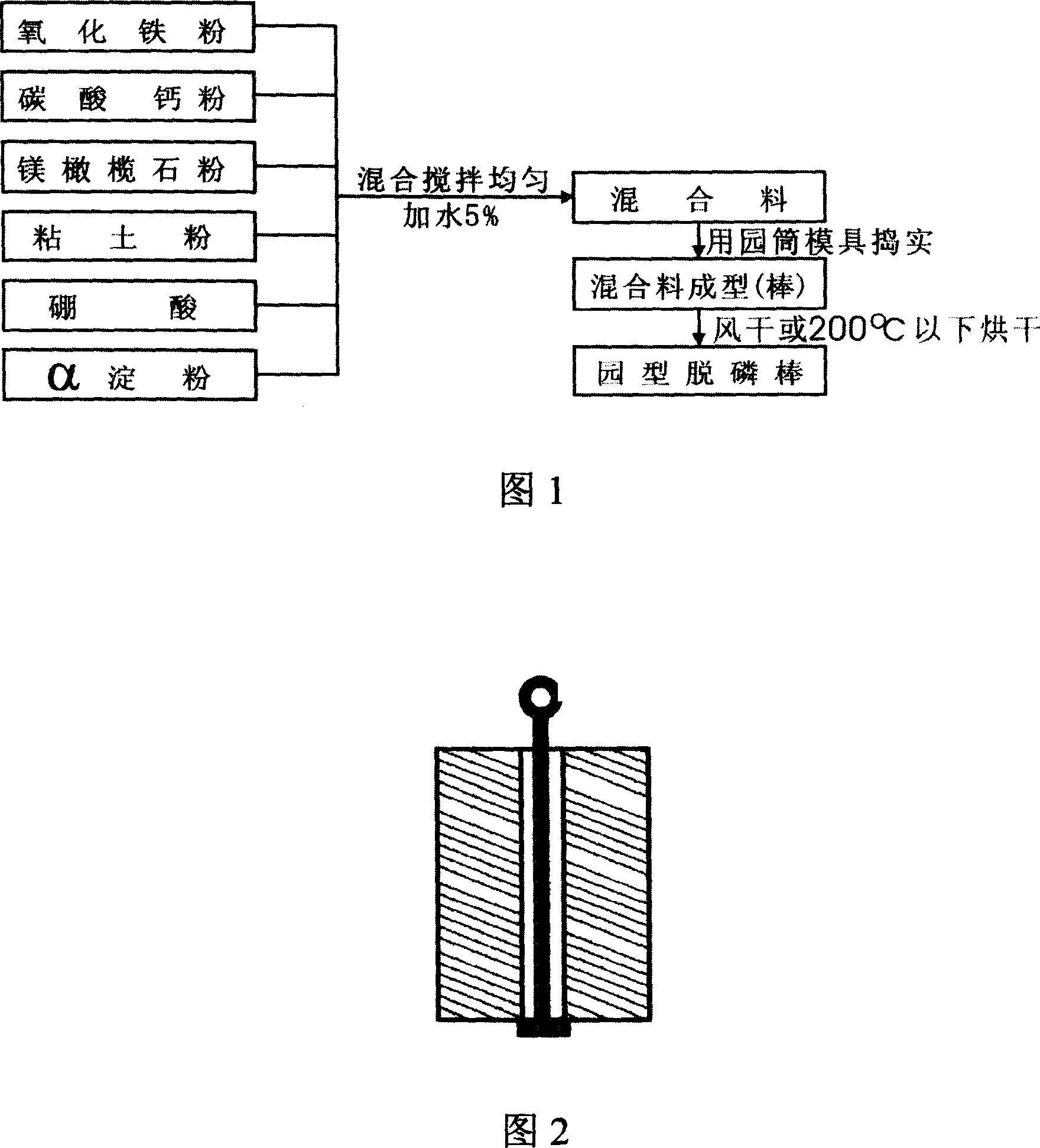

[0021] To produce 1000kg of this stick, weigh: 640kg of iron oxide powder, 150kg of magnesia powder, 100kg of calcium carbonate powder, 70kg of clay powder, 20kg of boric acid, 20kg of a starch, mix through a 30-mesh sieve, add 5% of water, and press Domestic 0.5t / h, 1t / h, 5t / h, 10t / h power frequency or intermediate frequency electric furnace specifications can be made into bars with a weight of 10kg / piece, 20kg / piece, and 30kg / piece, and air-dried for later use. The consumption of rod is 1-2% of the weight of molten steel.

[0022] When in use, when the temperature of the molten steel in the furnace is 1350-1450°C, preheat the dephosphorization rod at the furnace mouth to about 200°C and then insert it into the molten steel, let it melt slowly naturally and diffuse in the boiling molten steel to remove phosphorus After dephosphorization, the phosphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com