Composite membrane electrode of direct borohydride fuel cell

A fuel cell and borohydride technology, which is applied to fuel cell components, fuel cells, battery electrodes, etc., can solve the problems of low total utilization rate of battery fuel and unavailability of hydrogen, and achieve a simple and compact overall structure and reduced volume. , The effect of reducing the internal pressure of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

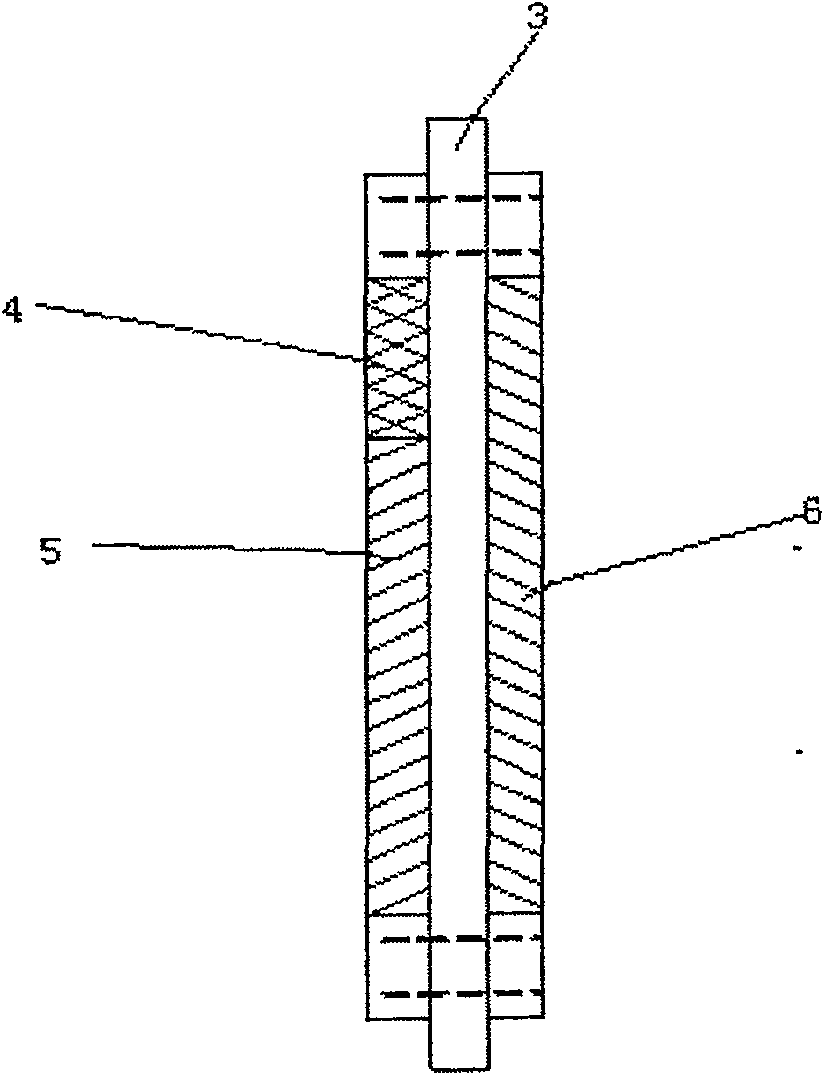

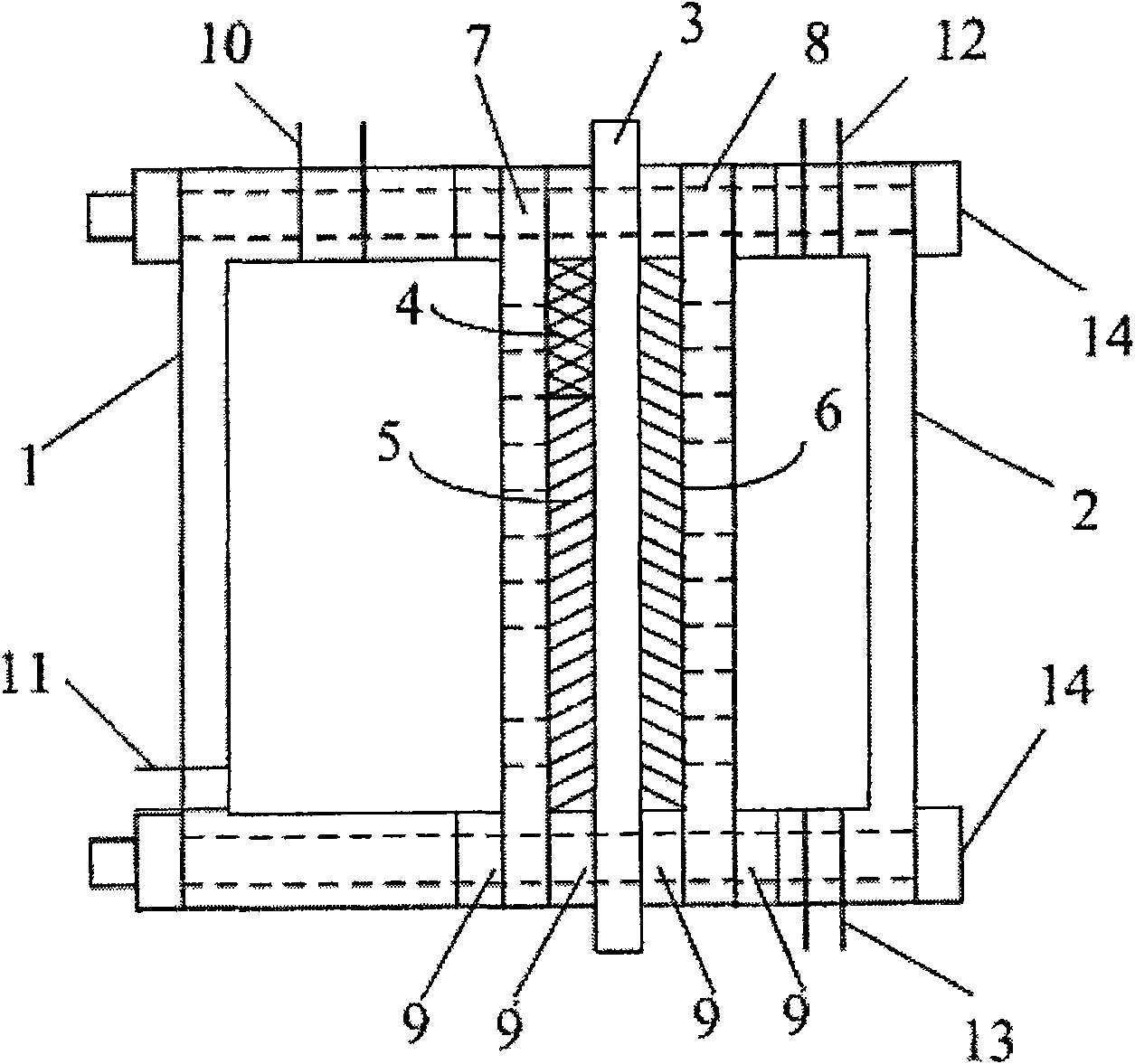

[0013] Embodiment 1: The composite membrane electrode of the direct borohydride fuel cell in this embodiment is composed of an anode, a cathode 6 and an electrolyte membrane 3. The anode and the cathode 6 are respectively located on both sides of the electrolyte membrane 3 and parallel to the electrolyte membrane 3. The three Hot-pressed film-forming electrode; the anode is composed of a borohydride catalytic oxidation anode 5 and a hydrogen catalytic oxidation anode 4, the hydrogen catalytic oxidation anode 4 is located at the upper part of the anode, and the borohydride catalytic oxidation anode 5 is located at the lower part of the anode.

specific Embodiment approach 2

[0014] Embodiment two: the difference between this embodiment and embodiment one is: borohydride catalytic oxidation anode 5 is made of carbon paper and a catalyst sprayed on the carbon paper, and both the carbon paper and the catalyst carry out hydrophilic treatment; Directly adopt active ingredient porous structure, active ingredient powder particles or composed of active ingredient and carrier; the active ingredient is Pt, Au, Ni, Pd, Ag, Ir, Os, Sn, Mo, W, V, PtO, PtO 2 , NiO, NiO 2 , Ni(OH) 2 , PdO, PdO 2 , AgO, Ag 2 O, SnO 2 、MoO 2 、MoO 3 , WC, WO 2 、WO 3 , V 2 o 5 One or more of them, when there are two or more active components, the components are mixed in any proportion; the carrier is carbon powder and carbon nanotubes. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this specific embodiment and specific embodiment two is: the catalyst does not directly adopt the porous structure of the active component without the carrier, wherein the active component is Pt, Au, Ni, Pd, Ag, Ir, Os, Sn, Mo, W, V, PtO, PtO 2 , NiO, NiO 2 , Ni(OH) 2 , PdO, PdO 2 , AgO, Ag 2 O, SnO 2 、MoO 2 、MoO 3 , WC, WO 2 、WO 3 , V 2 o 5 One or more of them; when there are two or more active ingredients, each component is mixed in any proportion. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com