Differential pressure low-energy-consumption distillation method and equipment

A technology of energy consumption and rectification, applied in the field of rectification, can solve the problems of matching heat exchange between the top condenser and the column bottom reboiler, and the inability to realize thermal coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

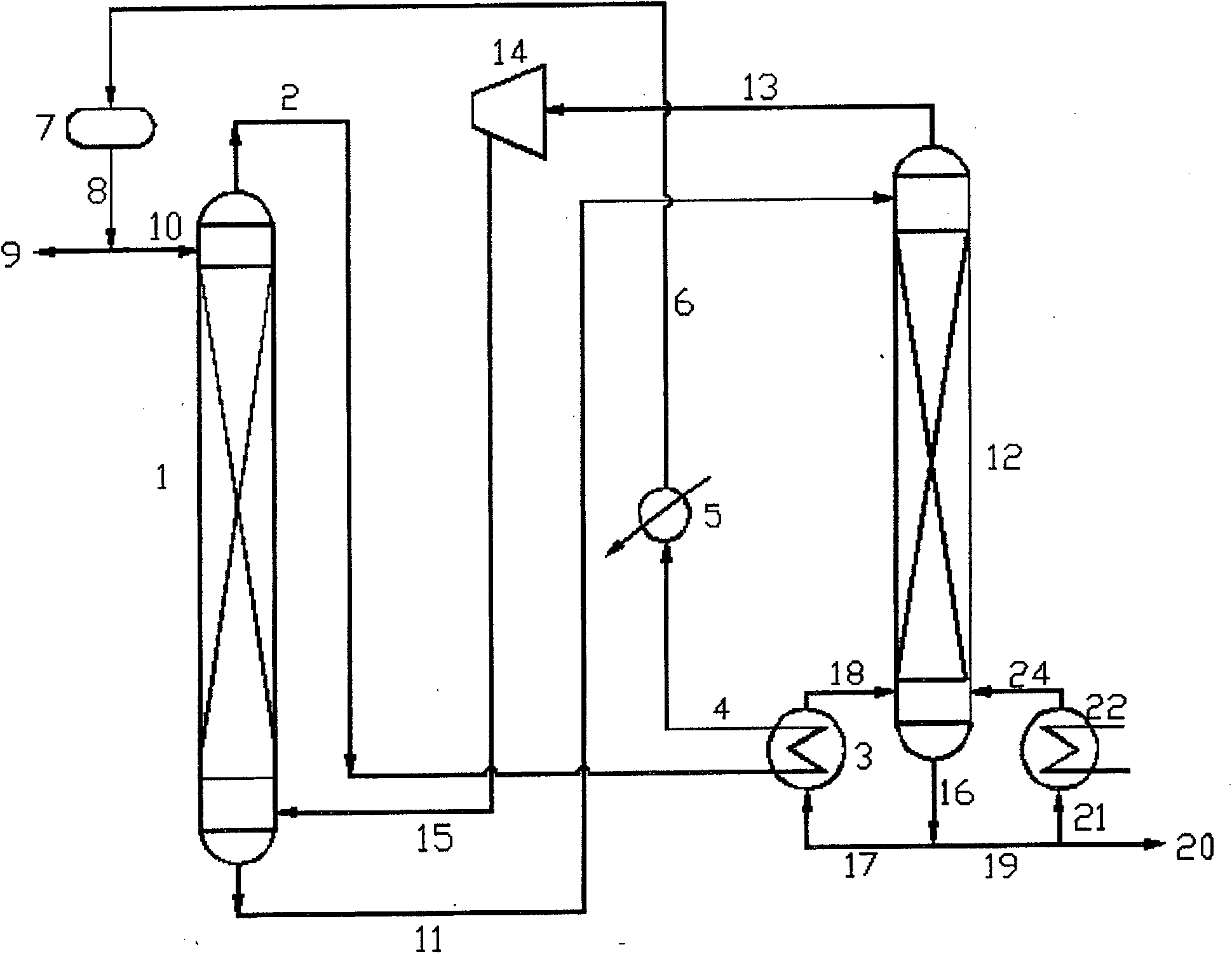

[0024] The technology and equipment provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The present invention is achieved through the following technical solutions:

[0026] Such as figure 1 As shown, the liquid phase material at the bottom of the tower after being separated by the conventional separation tower section 1 enters the top of the decompression separation tower section 12 under pressure differential push; the steam 13 coming out of the top of the decompression separation tower section enters the conventional The bottom of the separation column section is used as rising steam 15; part of the liquid phase 16 from the bottom of the decompression separation column section can be extracted as a product 20, and the other part 17 is in the main reboiler 3 with the steam 2 from the top of the conventional separation column section Perform heat exchange to form the reboil steam 18 required at the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com