Polymer lithium ion battery preparation technique and products

A technology of lithium-ion batteries and ion batteries, which is applied in the manufacture of secondary batteries, battery components, and final products, can solve the problems of insufficient ability to adsorb precursor solutions, high battery manufacturing costs, and low manufacturing costs, and achieve improved High current charge and discharge performance and cycle performance, low battery manufacturing cost, and the effect of achieving large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

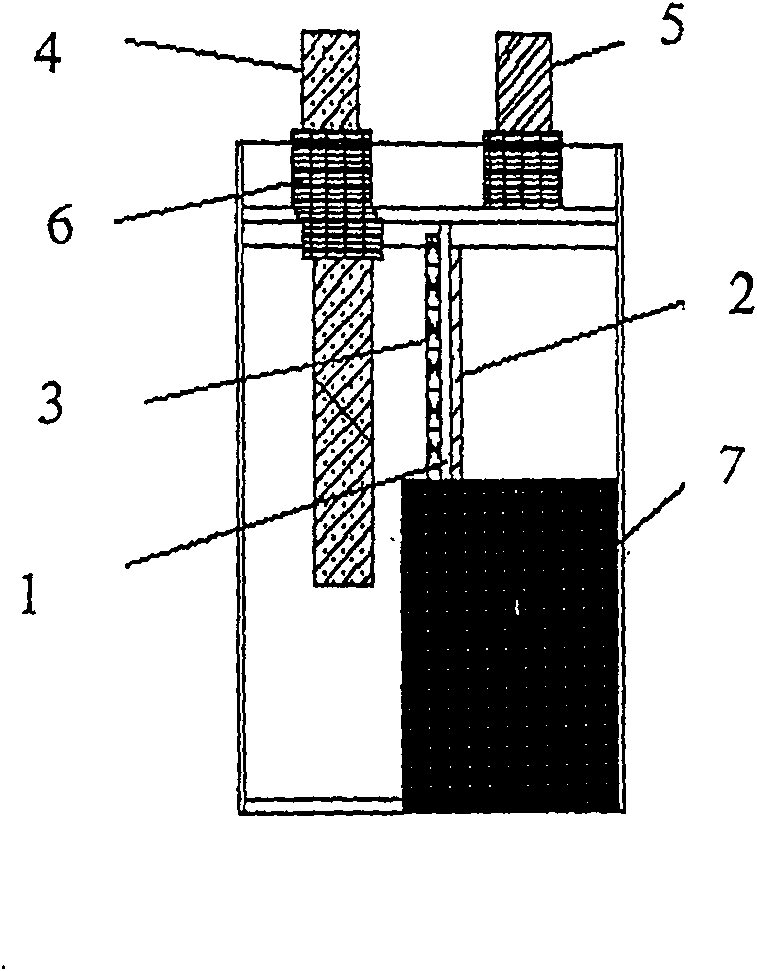

[0040] Prepare as follows figure 1 The polymer battery shown, figure 1 Among them, reference numeral 1 denotes the polymer three-dimensional network structure layer, 2 denotes the positive electrode, 3 denotes the negative electrode, 4 denotes the positive electrode tab, 5 denotes the negative electrode tab, 6 denotes the polymer adhesive layer, and 7 denotes the outer packaging shell.

[0041] 1. Preparation of modified diaphragm:

[0042] After mixing the crosslinking agent butanediol diacrylate and polyvinylidene fluoride in a mass ratio of 40%:60%, they were dissolved in an acetone solvent. By adjusting the amount of solvent, the viscosity of the modified liquid is controlled at about 70 psi. Then a polyethylene microporous membrane with a thickness of 16 microns was dipped in the above modification solution. After drying, a modified separator with a thickness of 20 microns was obtained.

[0043] 2. Prepare the positive and negative electrodes of the battery:

[0044]...

Embodiment 2

[0053] 1. Preparation of modified diaphragm:

[0054] After mixing the cross-linking agent pentylene glycol diacrylate and the polyvinylidene fluoride-hexafluoropropylene copolymer in a mass ratio of 15:85, they were dissolved in a tetrahydrofuran solvent. By adjusting the amount of solvent, the viscosity of the modified liquid is controlled at about 100 psi. Then, the polyethylene-polypropylene composite microporous membrane with a thickness of 25 microns was dipped in the above modification solution. After drying, a modified separator with a thickness of 35 microns was obtained.

[0055] 2. Prepare the positive and negative electrodes of the battery:

[0056] The pentanediol diacrylate was weighed according to 0.25% and 0.5% of the solid content of the positive electrode and negative electrode slurries, respectively, and added to the positive electrode and negative electrode slurries respectively. After stirring evenly, the pole piece is prepared according to the pole pie...

Embodiment 3

[0065] 1. Preparation of modified diaphragm:

[0066] The polyvinylidene fluoride-hexafluoroethylene was dissolved in the acetone solvent, and the viscosity of the modified liquid was controlled to be about 40 psi by adjusting the amount of the solvent, and then the polyethylene-polypropylene microporous membrane with a thickness of 20 microns was immersed in the above modification. After drying, a modified diaphragm with a thickness of 25 microns was obtained.

[0067] 2. Prepare the positive and negative electrodes of the battery:

[0068] The pentanediol diacrylate was weighed according to 0.02% and 0.04% of the solid content of the positive electrode and negative electrode slurries, respectively, and added to the positive electrode and negative electrode slurries respectively. After stirring evenly, the pole piece is prepared according to the pole piece production process of the liquid lithium battery.

[0069] 3. Preparation of battery core:

[0070] According to the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com