Making method for CMOS thin film transistor

A technology of oxide semiconductors and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as manufacturing process defects, lengthy and complicated manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

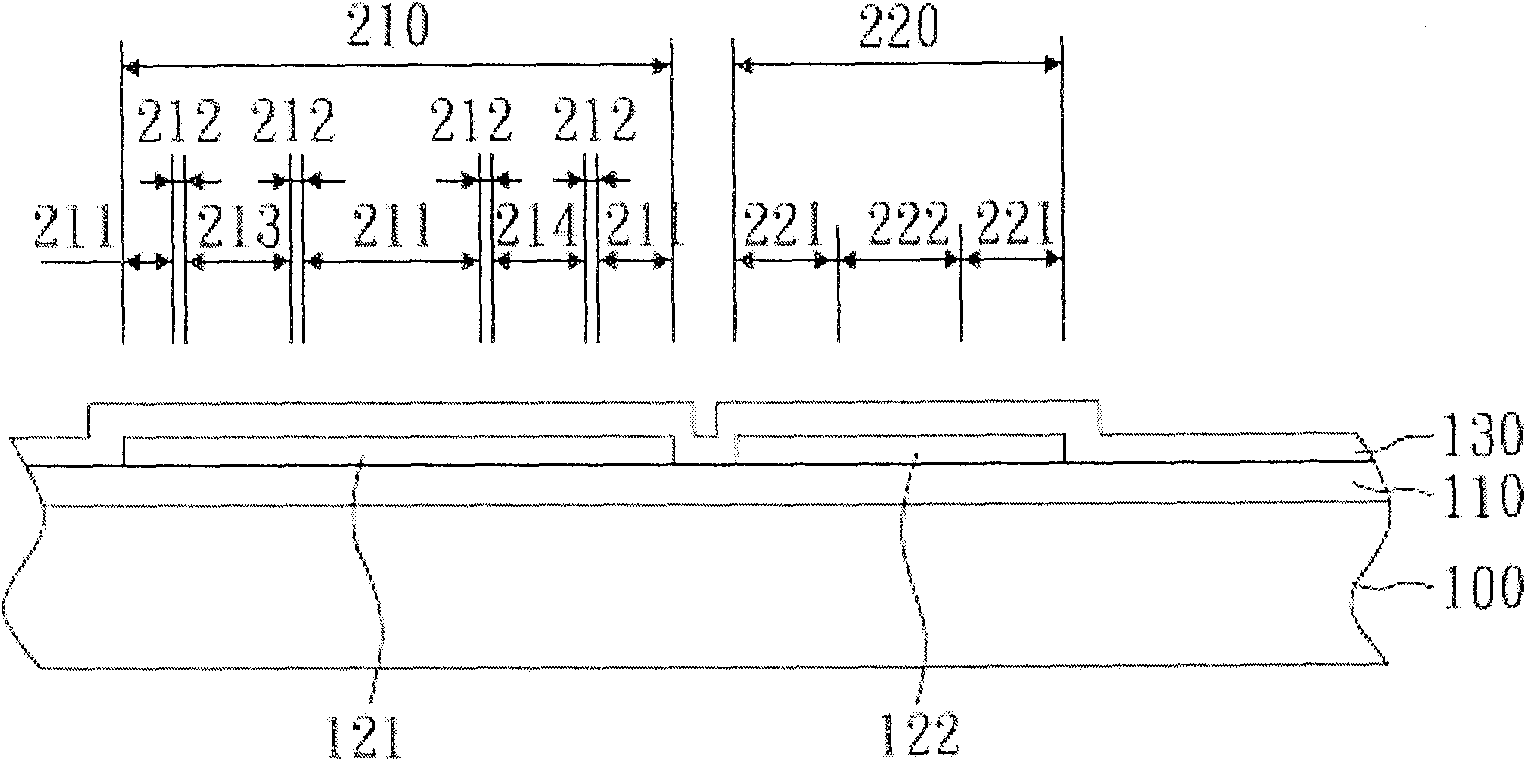

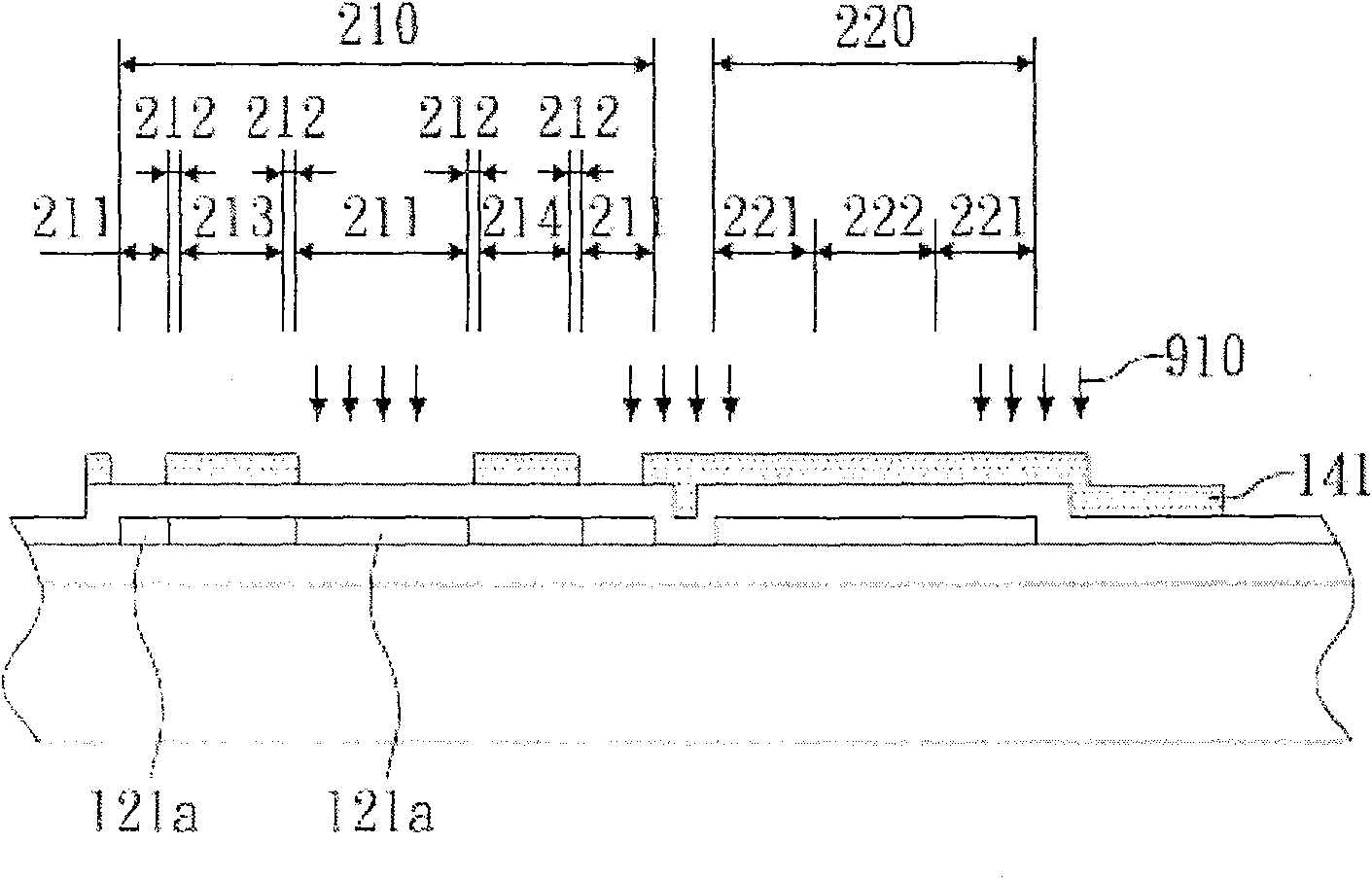

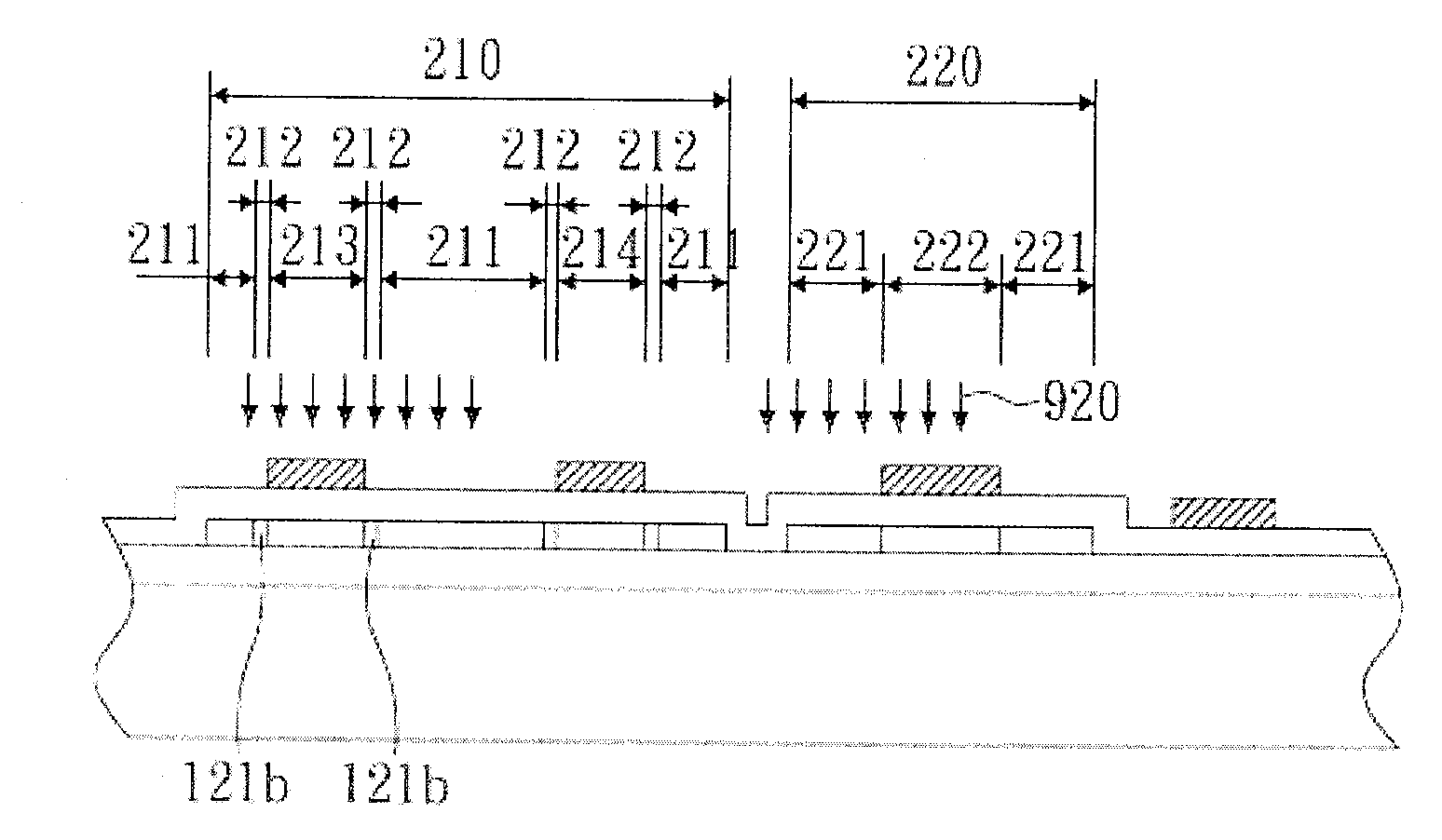

[0079] Figure 2A to Figure 2H The manufacturing method of an embodiment of a semiconductor device of the present invention is shown. This embodiment is a schematic diagram of a method for fabricating a thin film transistor array substrate using complementary metal oxide semiconductor thin film transistors. In the thin film transistor array substrate produced in this embodiment, the production of complementary metal oxide semiconductor thin film transistors and storage capacitors only requires two photomasks, and is designed with lightly doped drain (LDD) type NMOS elements and overlap (Overlap ) Type PMOS device to effectively improve the performance of complementary metal oxide semiconductor thin film transistors.

[0080] First, see Figure 2A , A substrate 300 is provided. The substrate 300 has an N-type metal oxide semiconductor (NMOS) region 510, a P-type metal oxide semiconductor (PMOS) region 520, and a capacitor region 530, wherein the NMOS region 510 includes a first T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com