Flat panel display with bevelled grid controlled cathode structure in truncated cone form, and fabricating technique thereof

A flat-panel display and cathode structure technology, which is applied in the manufacture of cold cathodes, control electrodes, and electrode systems, etc., can solve the problem that the working voltage of the gate structure remains high, the overall device cost is increased, and it is difficult to integrate driving circuits together. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

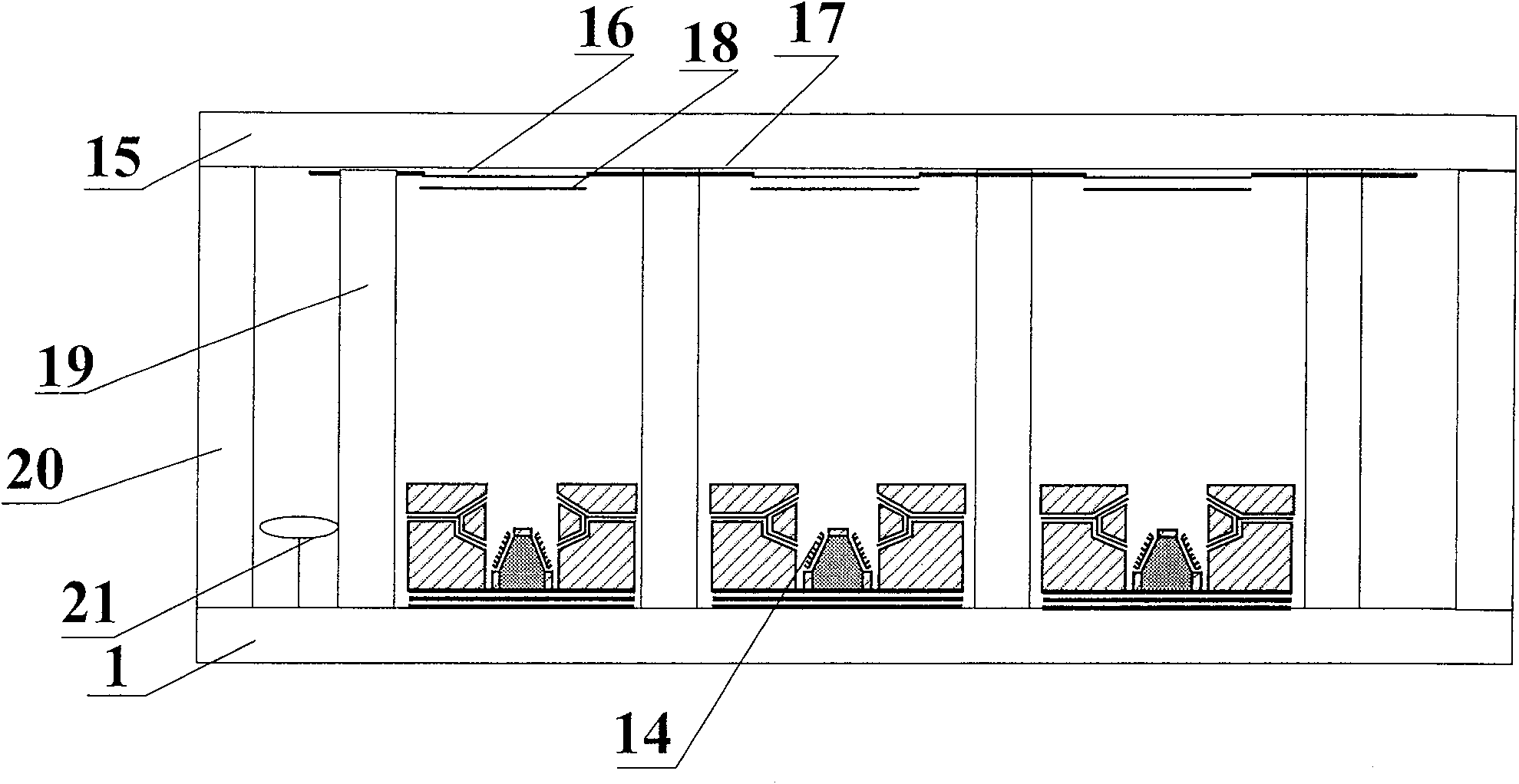

[0040] As shown in the figure, the present invention comprises the airtight vacuum chamber that is made of anode glass panel [15], cathode glass panel [1] and surrounding glass frame [20]; An anode conductive layer [16] is arranged on the anode glass panel and Phosphor layer [18] prepared on the anode conductive layer; there are cathode conductive layer [6], carbon nanotubes [14] and conical inclined grid cathode structure on the cathode glass panel; located between the anode glass panel and the cathode glass panel Supporting wall structure [19] and accessory elements of getter [21] between them.

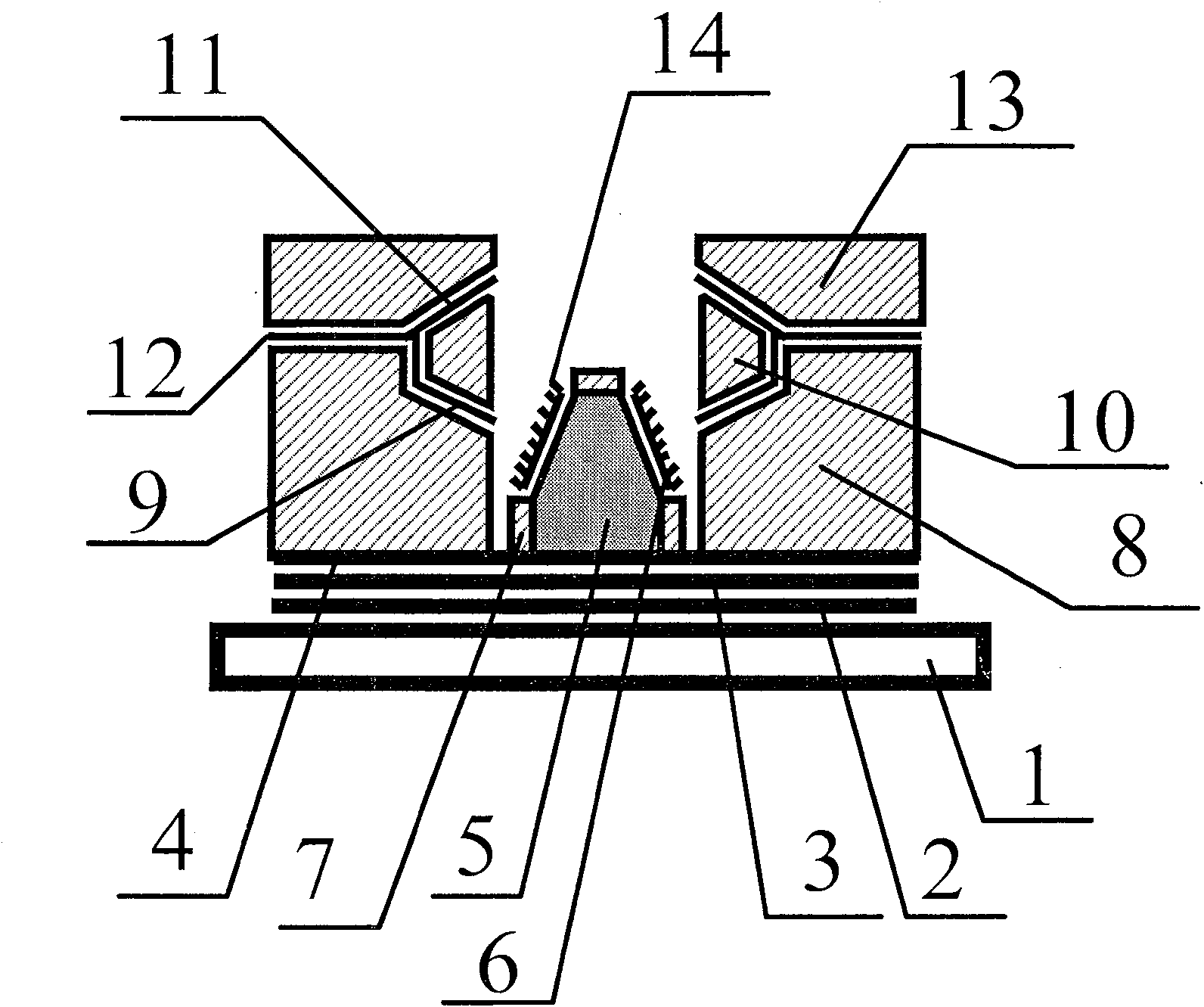

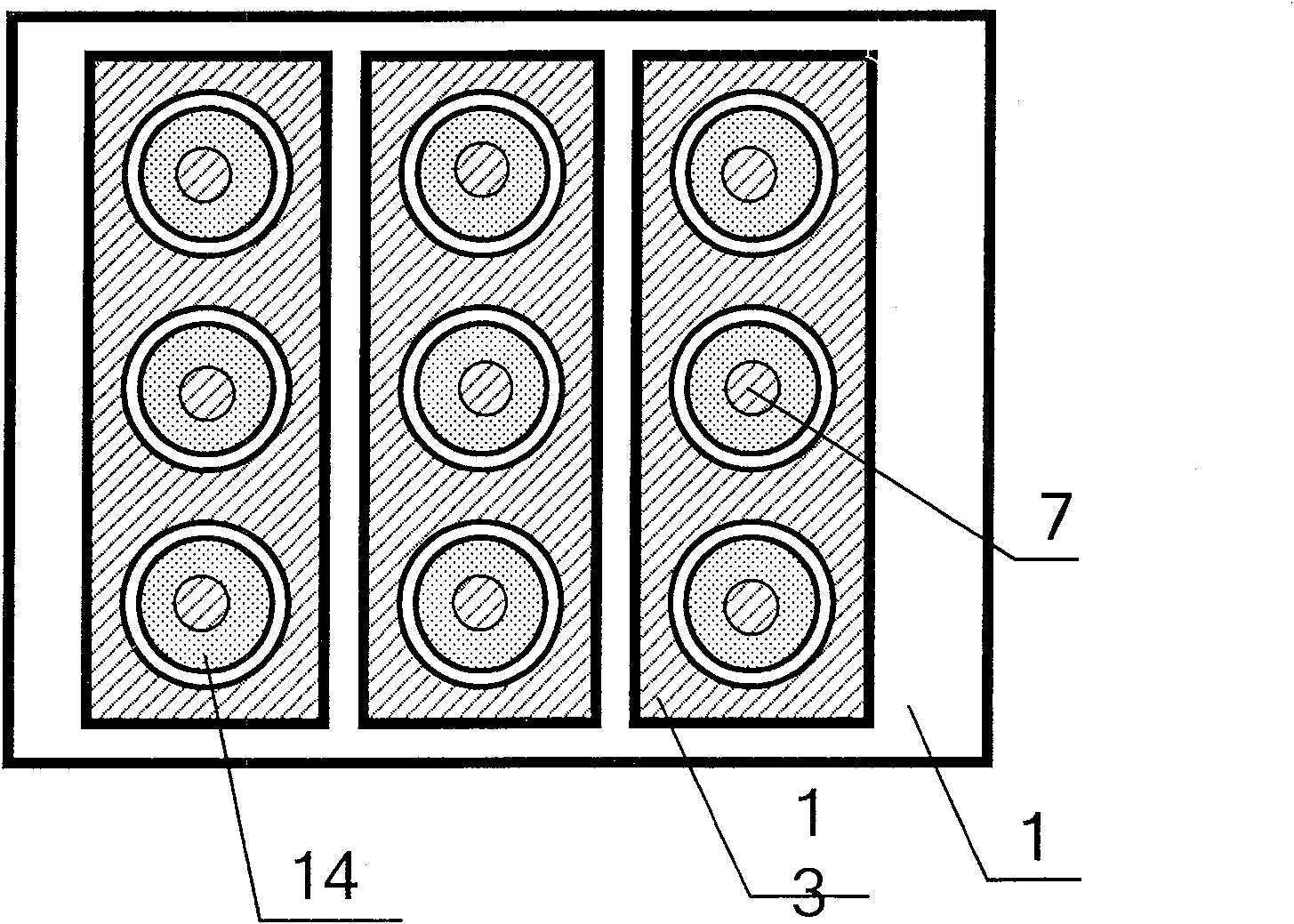

[0041] The frustum-inclined grid-controlled cathode structure includes a cathode glass panel [1], a retardation layer [2], a cathode lead layer [3], a cathode transition layer [4], a lifting layer [5], and a cathode conductive layer [6] , cathode cover layer [7], spacer layer [8], grid control layer [9], additional spacer layer [10], grid control layer two [11], grid lead layer [12]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com