Method of preparing nanometer scale coating

A flake and nano technology, applied in the field of preparation of nano flake coatings, to achieve the effects of strong anti-penetration ability, excellent adhesion, and high adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

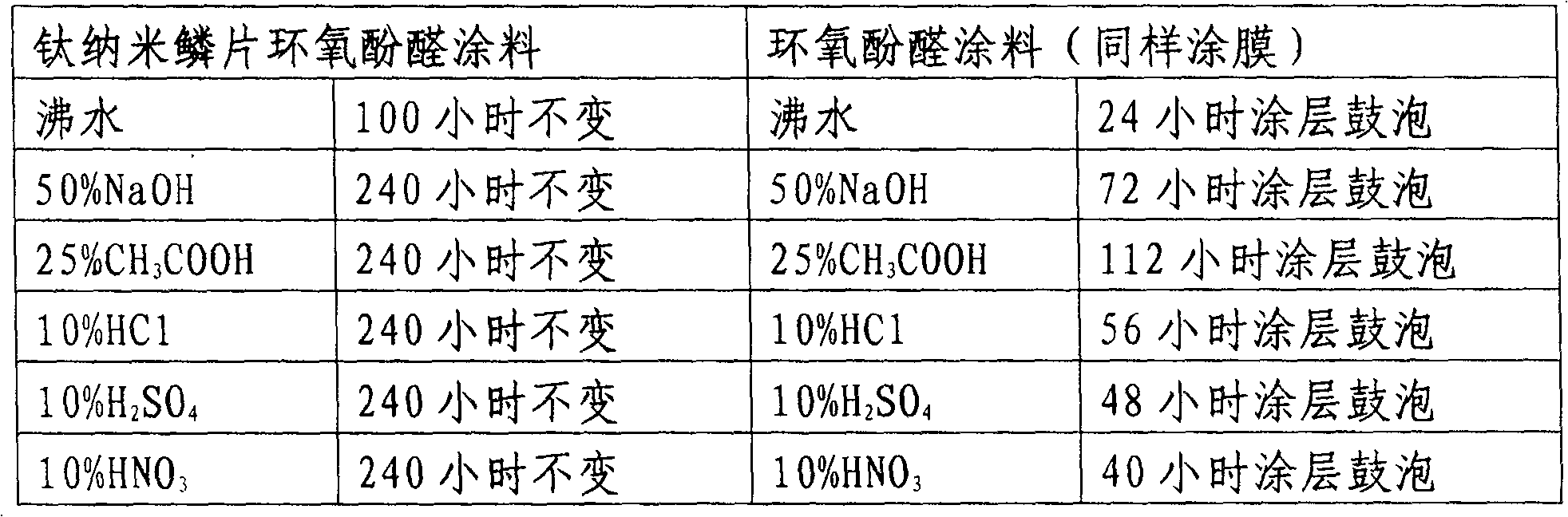

[0050] Titanium nano flake epoxy phenolic coating (high temperature curing type):

[0051] The coating is prepared by selecting titanium nano scales, the surface treatment agent is epoxy resin and polysulfide rubber, and the solvent is butanol, acetone and xylene.

[0052] 1. According to the pretreatment solution: epoxy resin 5g; polysulfide rubber 7g; xylene 40ml; butanol 20ml; acetone 40ml, dissolve the epoxy resin and polysulfide rubber in the above solvent for later use.

[0053] 2. According to the ratio of pretreatment liquid and titanium nano flakes: 100ml: 25ml, measure the pretreatment liquid and titanium nano flakes, and disperse them in a planetary ball mill for 4 hours to obtain active titanium nano flakes slurry.

[0054] 3. According to the ratio of 100g of epoxy phenolic coating and 10g of active titanium nano flake slurry, add the epoxy phenolic coating and active titanium nano flake slurry into the high-speed disperser. Mix and disperse in a high-speed dispe...

Embodiment 2

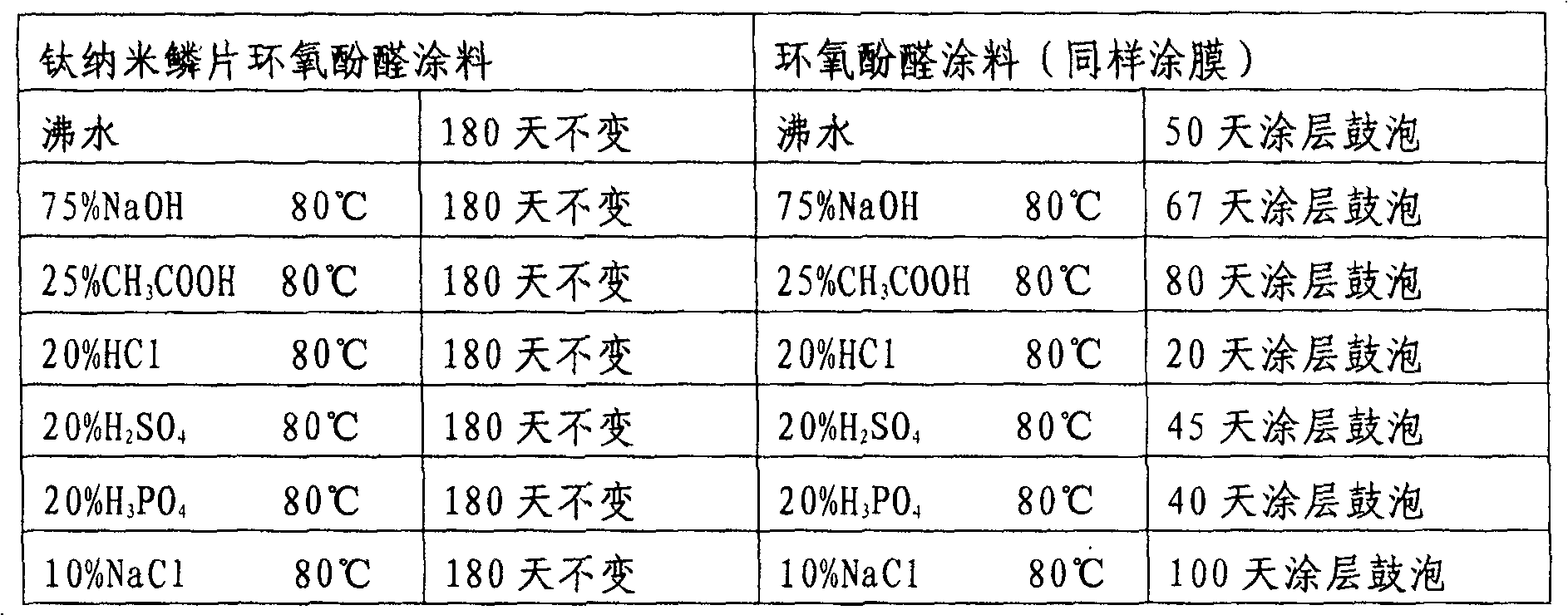

[0059] Titanium nano flake epoxy coating (room temperature curing type):

[0060] The coating is prepared by selecting titanium nano scales, the surface treatment agent is epoxy resin and polysulfide rubber, and the solvent is butanol, acetone and xylene.

[0061] 1. The active titanium nanoscale flake slurry of Example 1 is used.

[0062] 2. According to the ratio of epoxy coating 100g; active titanium nano flake slurry 10g, add epoxy coating and active titanium nano flake slurry into the high-speed disperser. Mix and disperse in a high-speed disperser for 30 minutes to obtain the finished titanium nano-scale epoxy coating.

[0063] Application effect:

[0064]The coating was applied with a dry film thickness of 50 μm in the first layer and dried at 20°C for 6 hours; a dry film thickness of the second layer was 75 μm and cured at 20°C for 7 days. The obtained coating film has the following properties:

[0065]

Embodiment 3

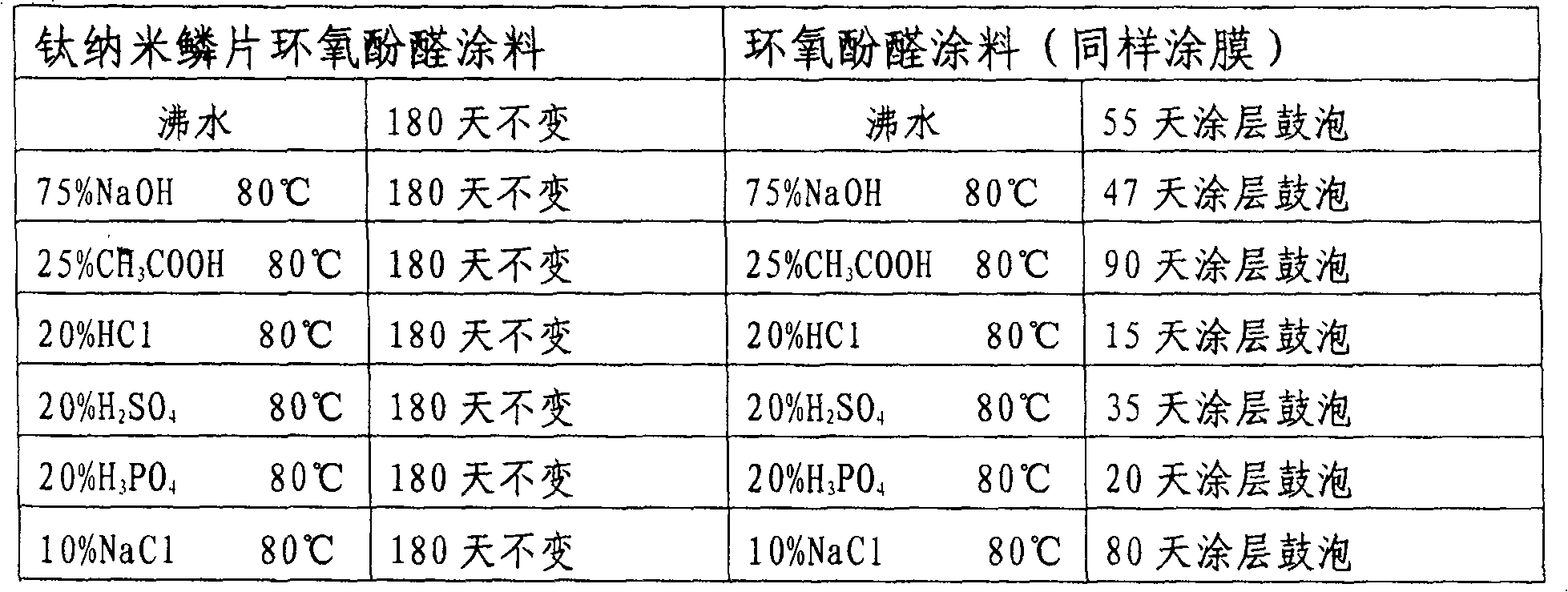

[0067] Glass nano flake epoxy coating (curing at room temperature):

[0068] The coating is prepared by selecting glass nano flakes, the surface treatment agent is epoxy resin and polysulfide rubber, and the solvent is butanol, acetone and xylene.

[0069] 1. According to the pretreatment solution: epoxy resin 5g; polysulfide rubber 7g; xylene 40ml; butanol 20ml; acetone 40ml, dissolve the epoxy resin and polysulfide rubber in the above solvent for later use.

[0070] 2. According to the ratio of pretreatment liquid and glass nano flakes: 100ml: 25ml, measure pretreatment liquid and glass nano flakes, and disperse them in planetary ball mill for 4 hours to obtain active glass nano flakes slurry.

[0071] 3. According to the proportion of epoxy coating 100g; active glass nano flake slurry 10g, add epoxy coating and active glass nano flake slurry into the high-speed disperser. Mix and disperse in a high-speed disperser for 15 minutes to obtain the finished glass nano flake epox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com