Deforming adjustable concrete component and preparation method thereof

A concrete structure and concrete technology, applied in the field of concrete components, can solve problems such as poor compatibility of concrete, complicated technical means, and short service life, and achieve the effects of low cost, simple operation, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

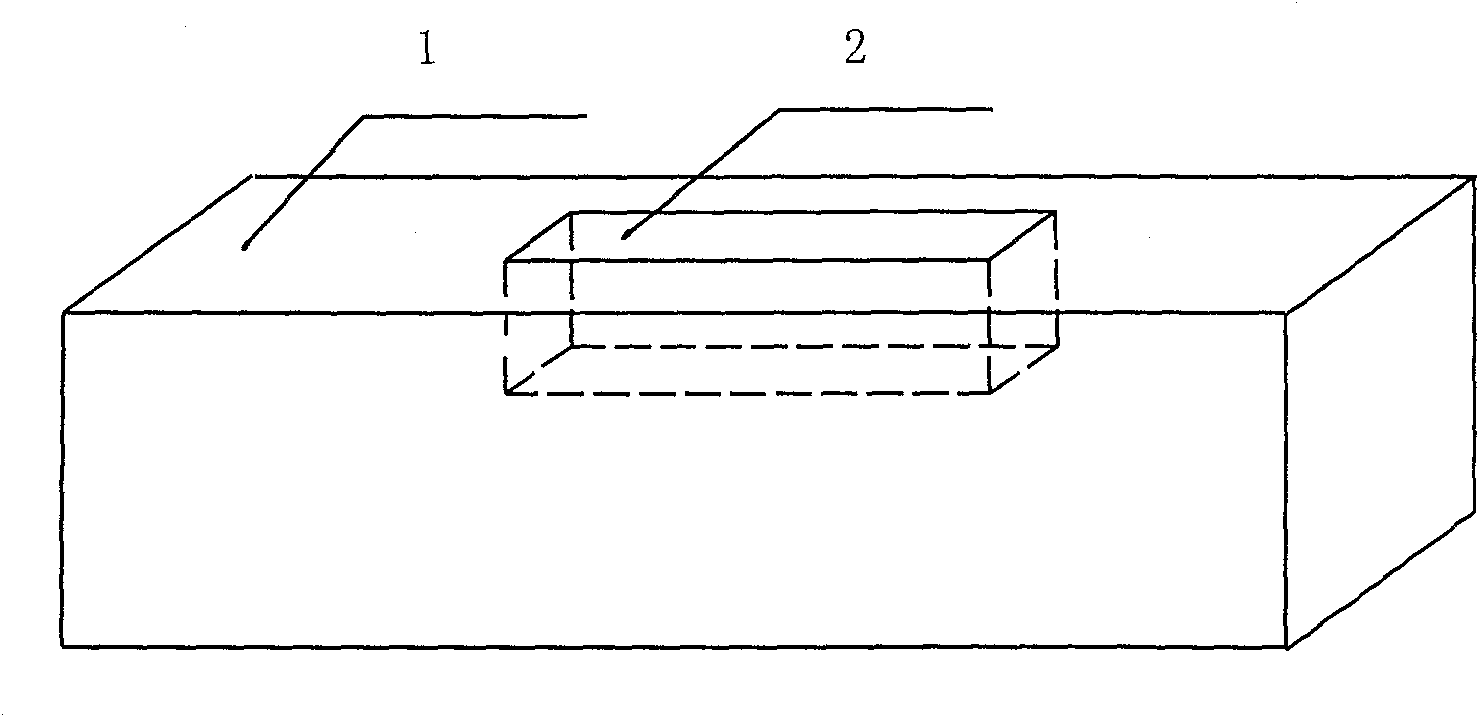

[0025] Example 1: Concrete Beam

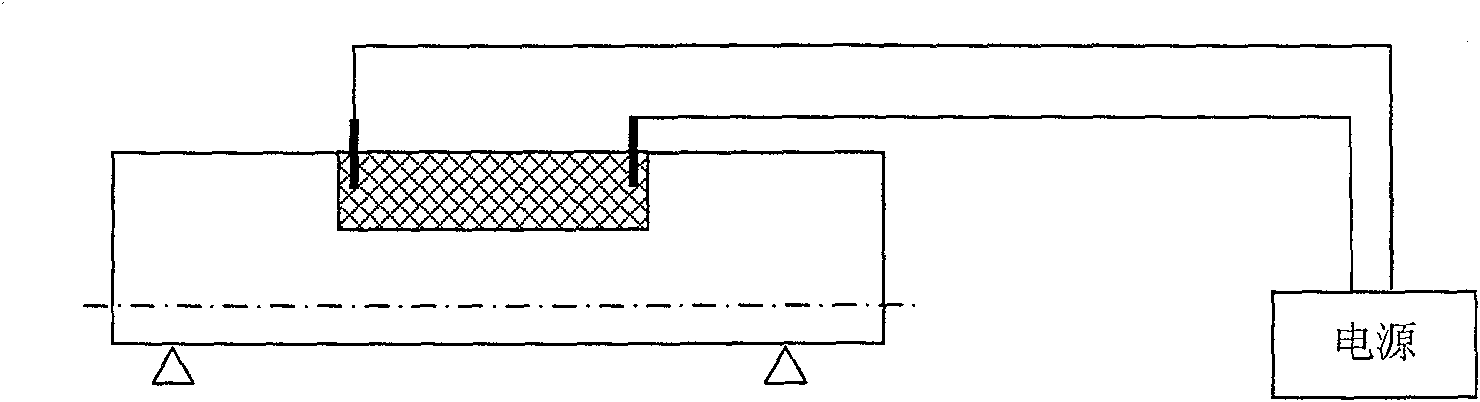

[0026] The length, width and height of the concrete beam are: 1200mm×300mm×300mm. The design strength grade of concrete is C35 (35MPa). While pouring the concrete of the beam main body 1, pour carbon fiber reinforced mortar at the mid-span of the beam and above the axis at the same time, and its length, width and height dimensions are: 480mm×120mm×120mm. The upper surface of the carbon fiber reinforced mortar block 2 is located in the same plane as the upper surface of the beam 1 . Such as figure 1 shown. Inject the carbon fiber reinforced mortar into the formwork of the corresponding part of the main body, use a vibrator to vibrate for about 2 minutes to remove the internal air bubbles, and then place a stainless steel mesh electrode welded with wires at both ends of the mortar. The stainless steel mesh electrodes are all buried in the mortar. Lead out the mortar. The distance between the two electrodes is 400 mm. The design strength gr...

Embodiment 2

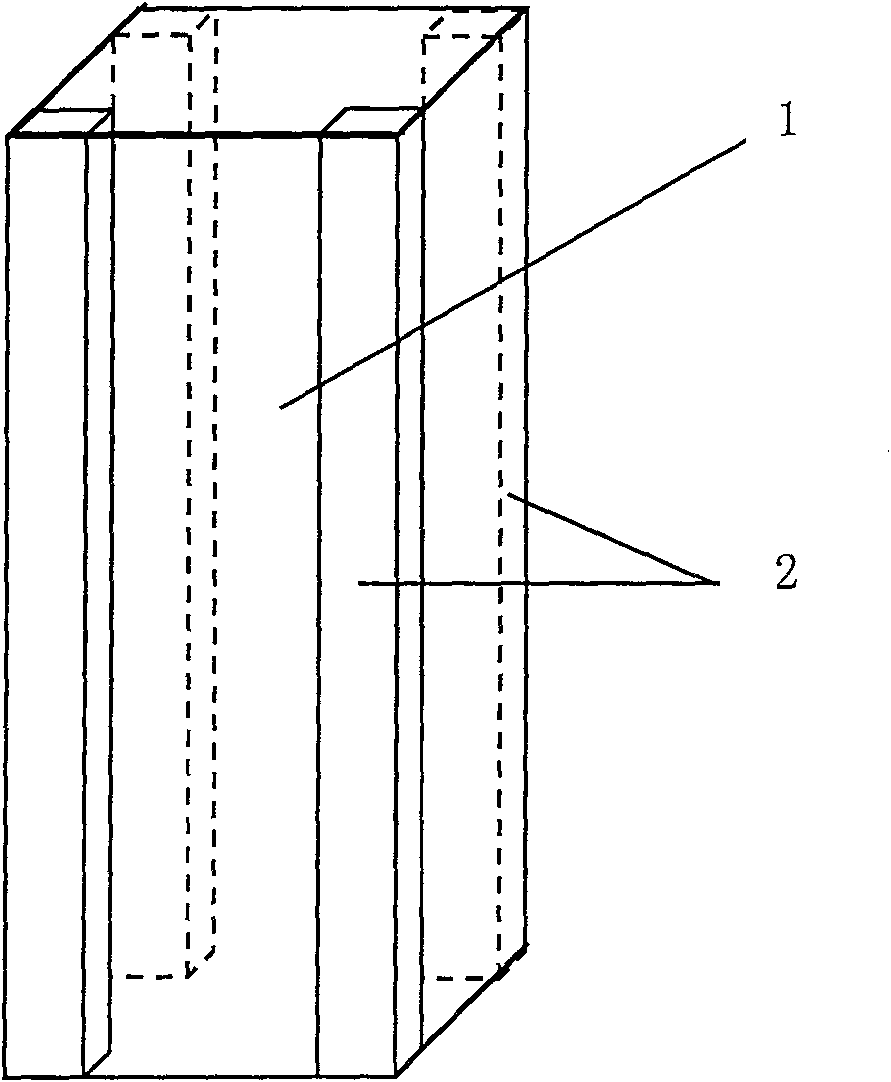

[0041] Example 2: Concrete columns

[0042] The section size of the concrete column is: 400mm×400mm, and the column height is 1200mm. The design strength grade of concrete is C35 (35MPa). Four carbon fiber reinforced mortar prisms are symmetrically poured at the four corners of the column main body 1, the height of which is the same as that of the concrete column, and the cross-sectional size of each prism is 80mm×80mm, such as figure 2 shown. A stainless steel electrode is respectively placed at the upper and lower ends of each carbon fiber reinforced mortar block 2, and is connected with a wire for use. The design strength grade of the mortar is M50 (50MPa).

[0043] The distribution ratio of the components used in the carbon fiber reinforced mortar and the performance after 28 days are the same as in Example 1.

[0044] Place the concrete column vertically, two carbon fiber reinforced mortar prisms A and C are located on the left facade, and the other two carbon fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com