Production technique of tert-butyl glycinate adapted for industrial production

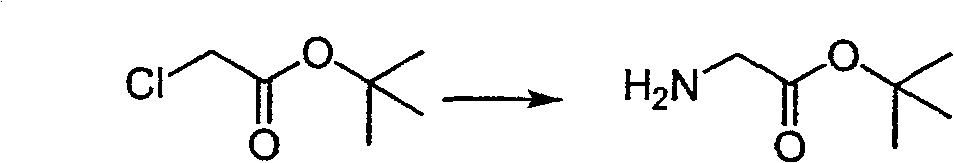

A technology suitable for industrial production of tert-butyl glycine, which is applied in the field of production technology of tert-butyl glycine, can solve the problems of high price, limited source of raw materials, harmful environment of waste, etc., achieve mild chemical reaction conditions, simple waste treatment method, cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

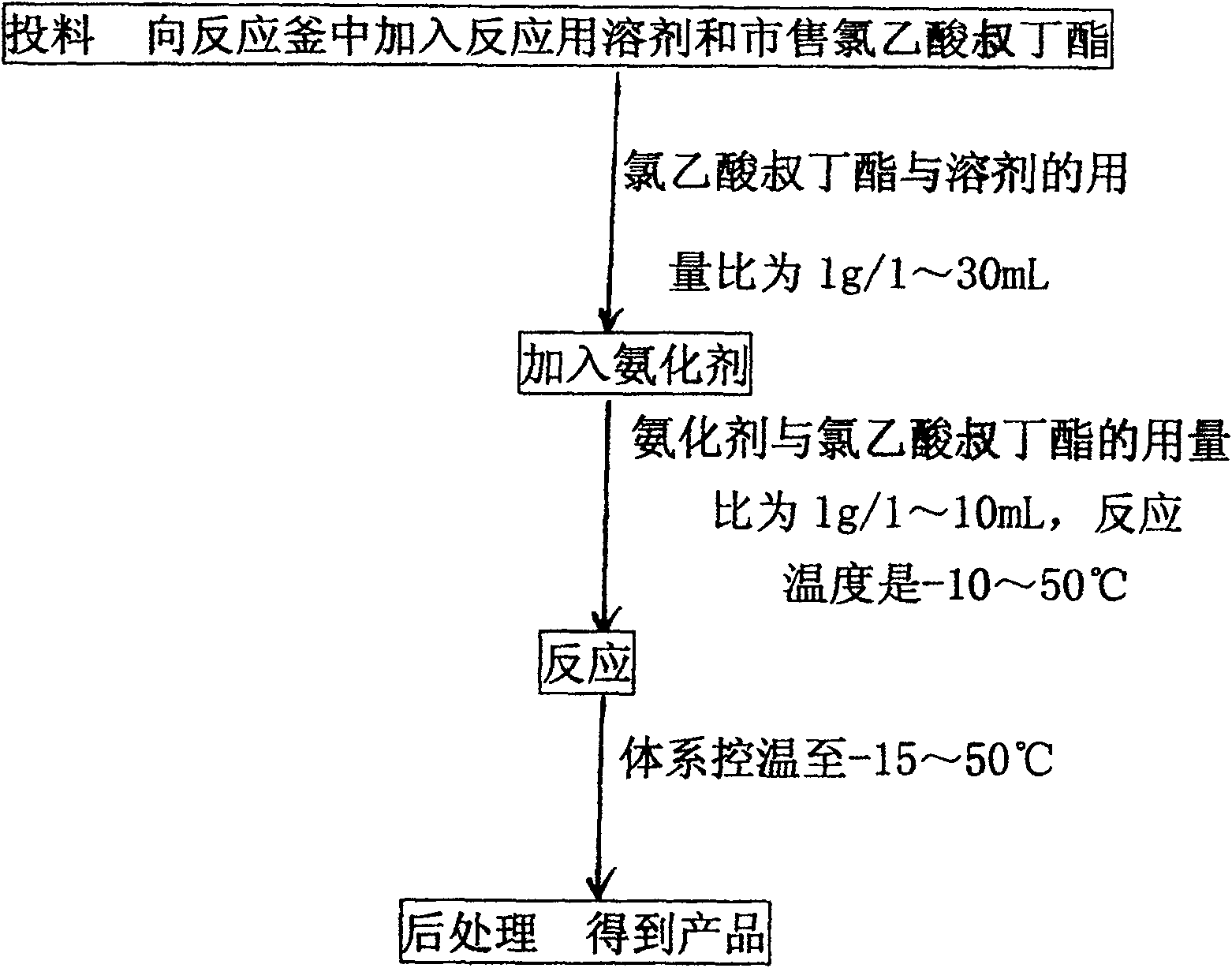

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: prepare glycine tert-butyl ester:

[0024] Inject 61kg of methyl tert-butyl ether and 20kg of tert-butyl chloroacetate into the 200L reactor at one time, and start stirring. At room temperature, feed 50 kg of liquid ammonia into the system. The system was warmed up to 10°C, and kept at this temperature for reaction. After the system was press-filtered, the filtrate was concentrated to remove the solvent, and then rectified to obtain a colorless liquid with a yield of 70%, a purity of 99%, and a boiling point of 77°C / -01MPa. Ammonium chloride is produced during the production process.

[0025] 1HNMR (300MHz, CDCl3); δ1.470 (tert-butyl CH3, m), δ3.315 (CH2, d).

Embodiment 2

[0026] Embodiment 2: prepare glycine tert-butyl ester:

[0027] Inject 132kg of cyclohexane and 13kg of tert-butyl chloroacetate into the 500L reactor at one time, start stirring, and then inhale 130kg of ammonia solution to ensure that the system is airtight and absorb exhaust gas. Slowly raise the temperature of the system to 40°C. The reaction was incubated at this temperature for 6 h. After extraction, the organic phase was dried, concentrated to remove the solvent, and rectified to obtain a colorless liquid with a yield of 65% and a purity of 96%. Ammonium chloride is produced during the production process.

Embodiment 3

[0028] Embodiment 3: prepare glycine tert-butyl ester:

[0029] 133kg of tetrahydrofuran and 6kg of butyl chloroacetate were pumped into a 200L reactor, and then 35kg of liquid ammonia solution was added. The system was heated to 50°C and kept at this temperature for 12h. The system was filtered by pressure and washed with water. After extraction, the organic phase was concentrated to remove the solvent, and rectified to obtain a colorless liquid with a yield of 72% and a purity of 97%. Ammonium chloride is produced during production.

[0030] Find out clearly according to above-mentioned embodiment: the production technology of the glycine tert-butyl ester that this kind is suitable for industrial production can obtain the high target product of purity, in the whole production process, solvent all can be recycled, and the waste material that produces is mainly ammonium salt, It is a commonly used chemical raw material, can be used, and is a feasible and low-pollution synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com