Method for encapsulating active material for negative pole of Li-ion secondary battery

A negative electrode active material and secondary battery technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve problems such as incompleteness and uneven coating, and achieve high charge and discharge efficiency and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This example illustrates the method of the present invention for coating the negative electrode active material of a lithium ion secondary battery.

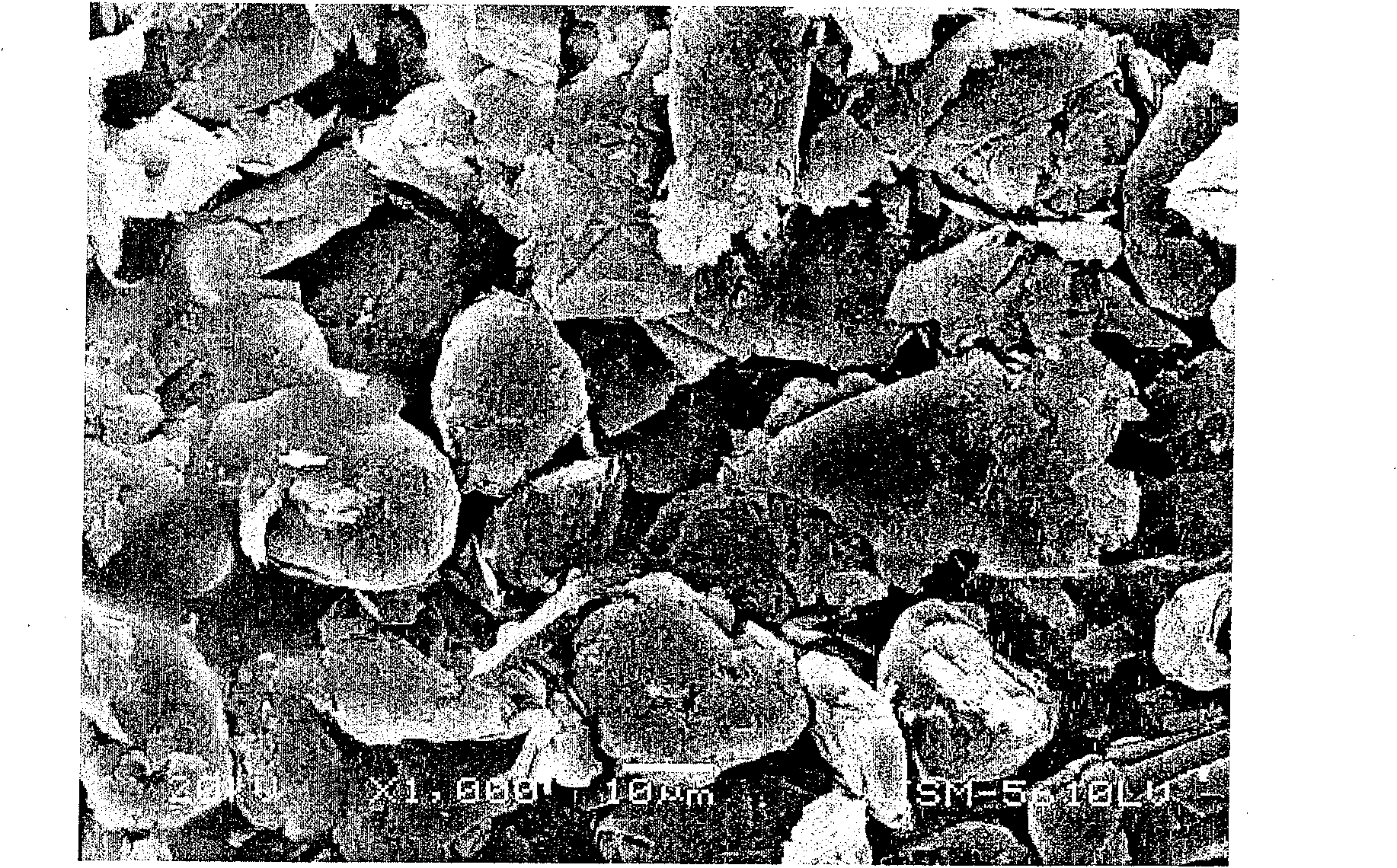

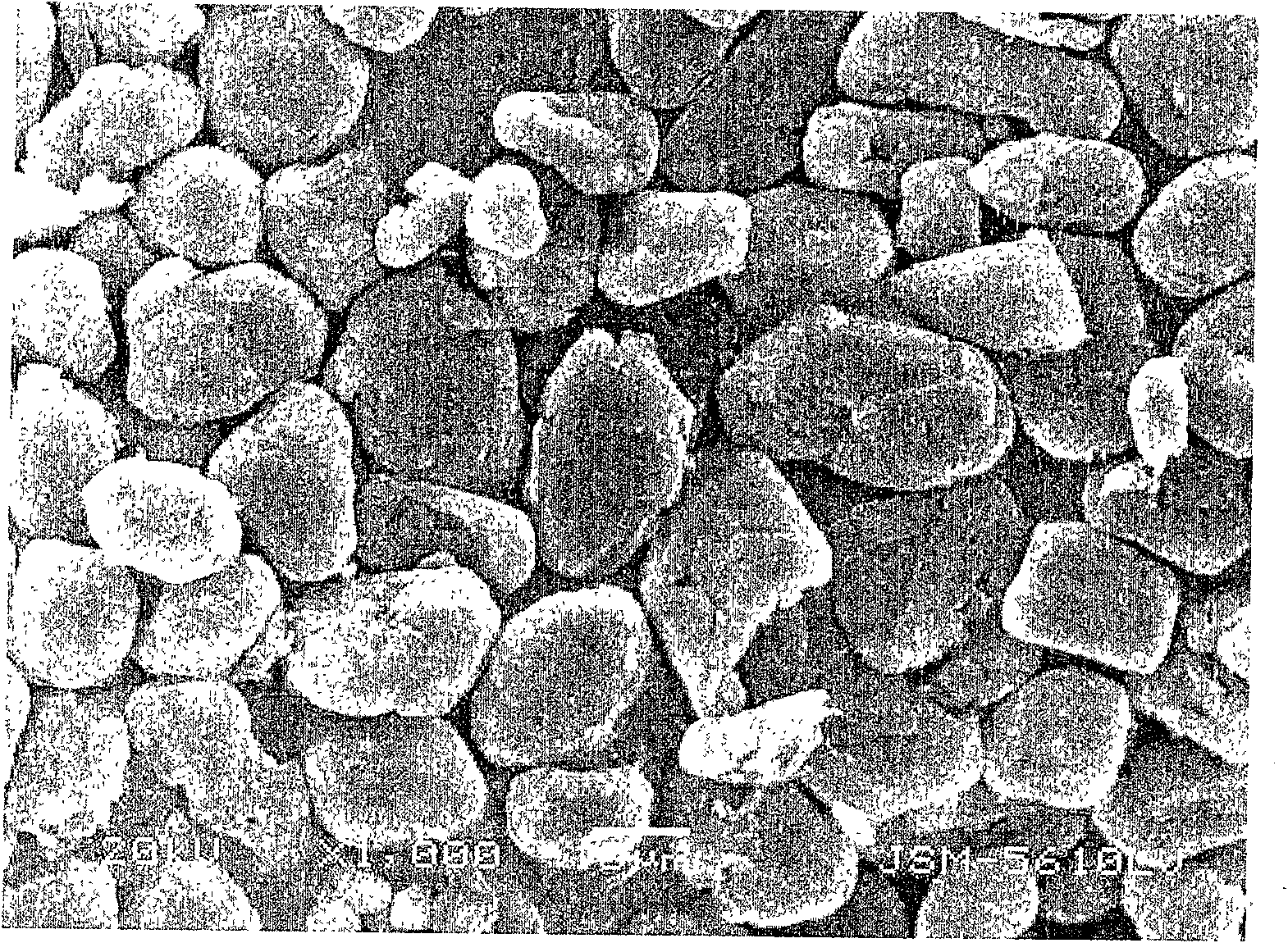

[0035] 2 kg of median particle size D 50 Be 17.54 microns, d002 corrected value of crystallite interlayer distance 0.33650 nanometers, specific surface area is 3.2 square meters per gram of natural graphite in XQM variable frequency planetary ball mill, after ball milling in Nanjing Keyan Experimental Research Institute (high energy ball mill) for 1 hour, add 0.1 kg of polystyrene, 10 g of dilauroyl peroxide, and continued ball milling for 3 hours to obtain graft-coated natural graphite particles. The graft-coated graphite was carbonized at 1200° C. for 2 hours in a nitrogen atmosphere to obtain natural graphite with a carbonized coating layer. The median particle size D of the carbonized natural graphite of the coating layer 50 It is 17.23 microns, the corrected value of d002 is 0.33652 nanometers, and the specific surf...

Embodiment 2-6

[0042] The negative electrode active material of lithium ion secondary battery is coated according to the method of embodiment 1, and difference is, the negative electrode active material of being coated and its median diameter D 50 , crystallite layer spacing d002 value, specific surface area, the weight ratio of the initiator and its coating agent, the weight ratio of the coating agent and the negative electrode active material, heating conditions, and the median particle size D50 of the negative electrode active material after coating , Crystallite layer spacing d002, specific surface area. See Table 1 for specific differences.

[0043] Table 1

[0044] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| face spacing | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com