Micro refrigerator and refrigeration method

A technology of micro-refrigerators and refrigeration methods, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of high field voltage, sensitivity of polarization rate with temperature changes, and continuous cycle and continuous net refrigeration effect. Achieve uniform and rapid heat transfer, large temperature drop, good cooling space uniformity and temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

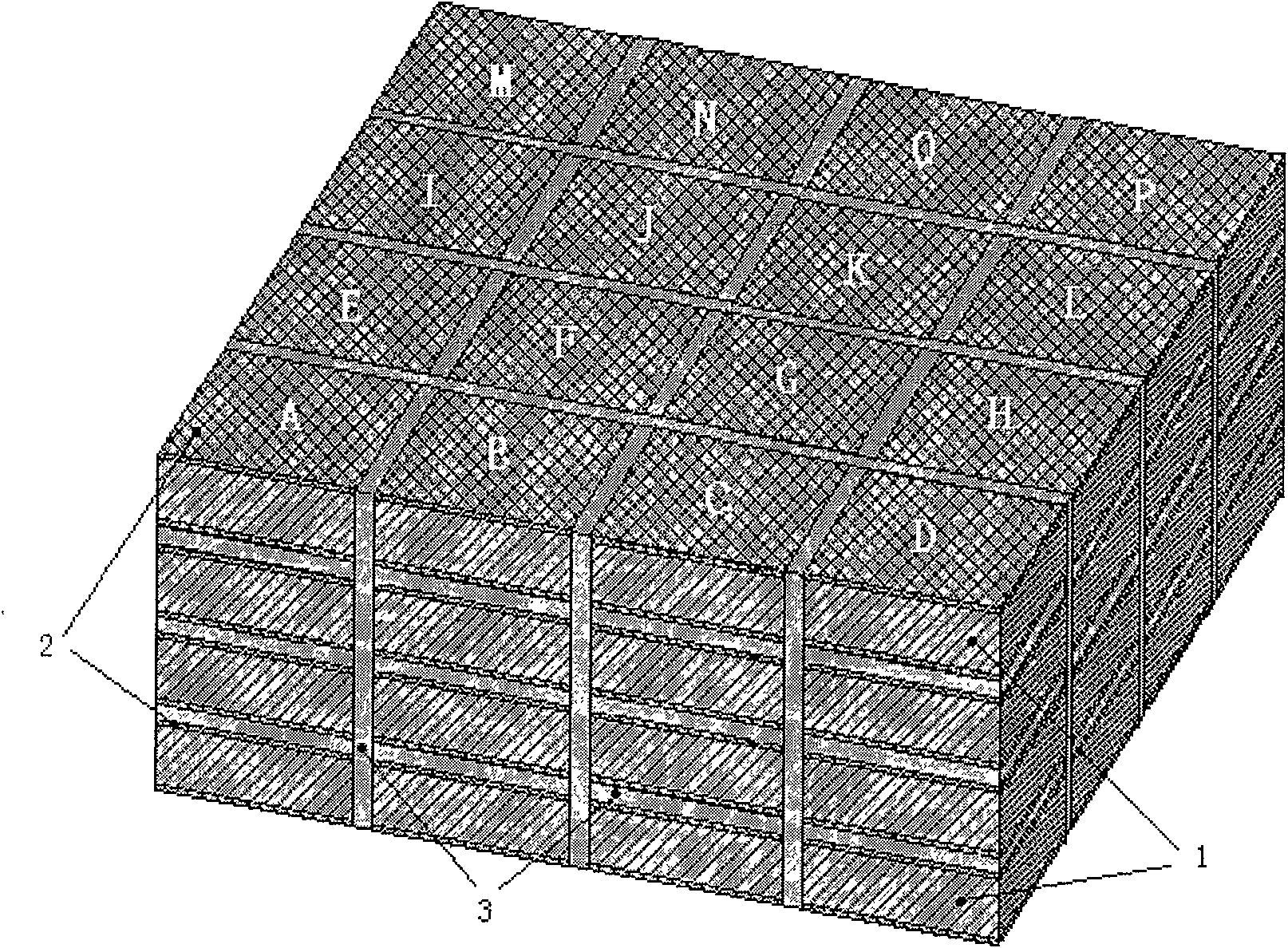

[0037] figure 1 Shown is the structure of the embodiment of the ferroelectric stack array microrefrigerator of the present invention. Such as figure 1 As shown, the ferroelectric stack array microrefrigerator of the present invention is composed of n layers of ferroelectric refrigeration sheets 1 and m rows x l columns of ferroelectric refrigeration sheets 1 stacked, electrodes and leads are sandwiched between the upper and lower sides of the refrigeration sheets 1. An insulating and heat-conducting insulating layer 3 made of an insulating and heat-conducting material made of PMNT or mica is sandwiched between layers and between rows and columns. The cooling sheet is made of PMNP or other ferroelectric materials with thermoelectric effect.

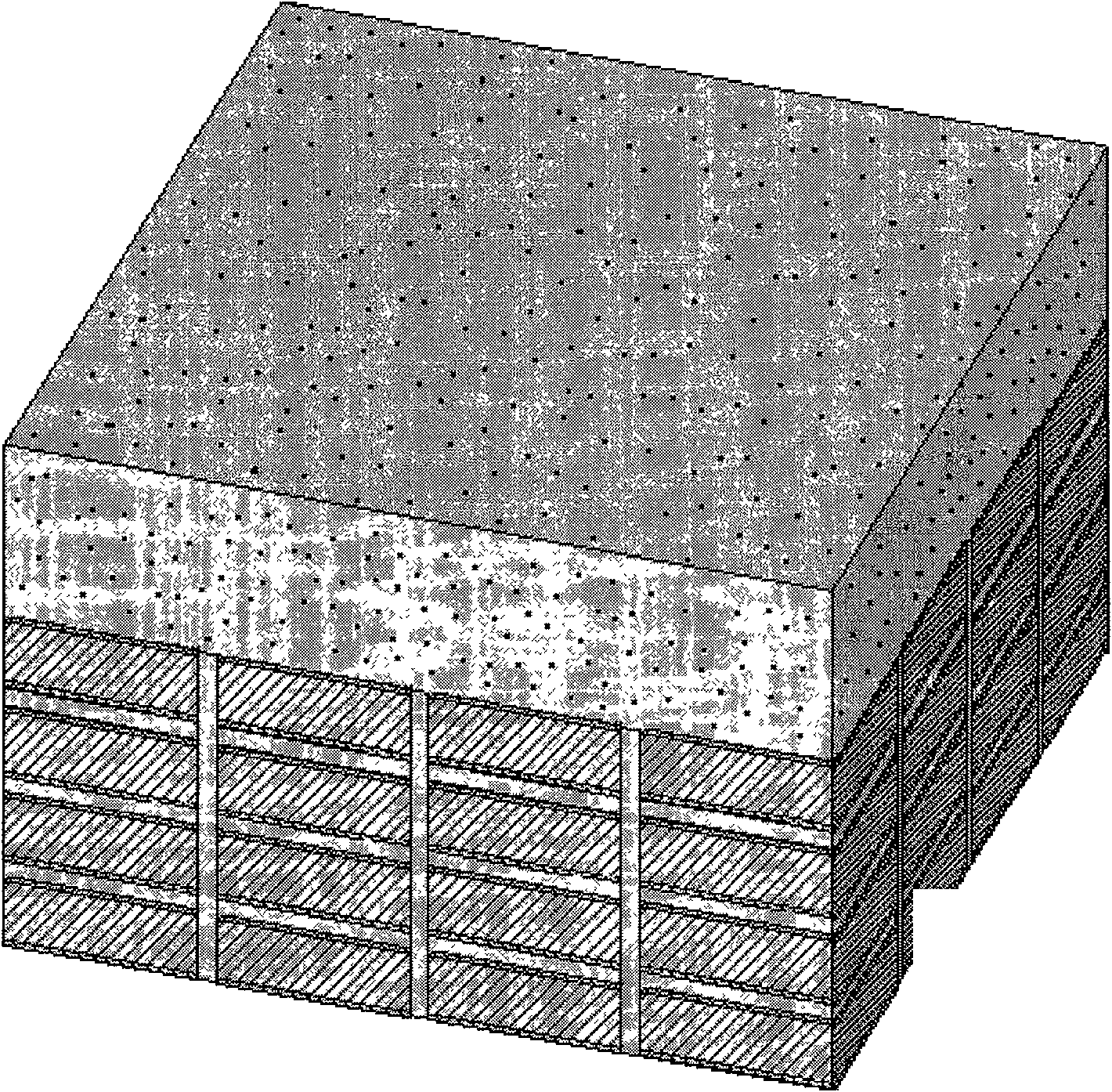

[0038] figure 2 It is a schematic diagram of an embodiment model of the combined state of the chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com