Ultra-hydrophobic polystyrene thin film enhanced by nano silicon dioxide particles and preparation method thereof

A technology of nano-silica and polystyrene film, applied in the field of superhydrophobic polystyrene film, to achieve the effect of wide application and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1). Coupling modification of nano-silica

[0035] Add 3 g of nano-silica particles with a particle size of 10-50 nm into a mixed solution of 3 ml of γ-aminopropyltrimethoxysilane and 45 ml of petroleum ether, and react for 24 hours under magnetic stirring. After the reaction, dry naturally until the solvent is completely volatilized, and bake in an oven at 80° C. for 2 hours to obtain surface-coupling-modified nano-silica particles.

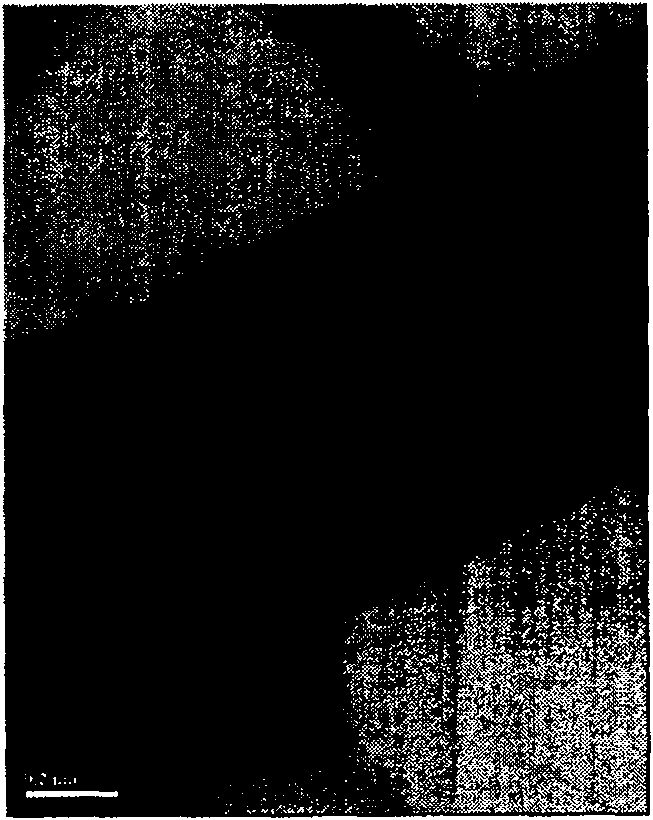

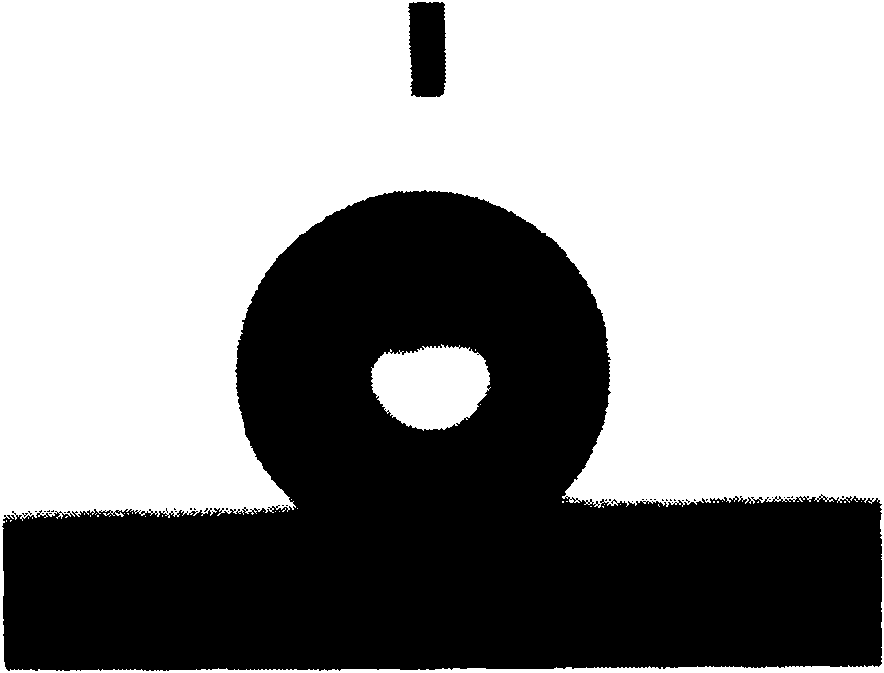

[0036] (2). Preparation of superhydrophobic polystyrene film

[0037] 0.025g modified SiO 2 The particles are placed in a solution of 0.5g polystyrene (weight average molecular weight: 200,000) and 9.5g N,N-dimethylformamide (DMF), and after being fully dispersed in an ultrasonic pool for tens of hours, they are passed through an electrospinning device Perform electrospinning to obtain a superhydrophobic polystyrene film reinforced by nano-silica particles with a composite structure of polystyrene / silica porous microspheres and nanofibe...

Embodiment 2

[0039] (1). Coupling modification of nano-silica

[0040] Add 3 g of nano-silica particles with a particle diameter of 20 nm into a mixed solution of 6 ml of methyltrimethoxysilane and 60 ml of octane, and react for 24 hours under magnetic stirring. After the reaction, dry naturally until the solvent is completely volatilized, and bake in an oven at 80° C. for 2 hours to obtain surface-coupling-modified nano-silica particles.

[0041] (2). Preparation of superhydrophobic polystyrene film

[0042] 0.025g modified SiO 2 The particles are placed in a solution of 0.375g polystyrene (weight average molecular weight: 300,000) and 5.6g N,N-dimethylformamide (DMF), and after being fully dispersed in an ultrasonic pool for tens of hours, they are passed through an electrospinning device Perform electrospinning to obtain a superhydrophobic polystyrene film reinforced by nano-silica particles with a composite structure of polystyrene / silica porous microspheres and nanofibers, wherein t...

Embodiment 3

[0044] (1). Coupling modification of nano-silica

[0045] Add 3 g of nano-silica particles with a particle size of 50 nm to a mixed solution of 3 ml of γ-aminopropyltrimethoxysilane, 6 ml of polydimethylsiloxane and 180 ml of petroleum ether, and react for 24 hours under magnetic stirring. After the reaction, dry naturally until the solvent is completely volatilized, and bake in an oven at 80° C. for 2 hours to obtain surface-coupling-modified nano-silica particles.

[0046] (2). Preparation of superhydrophobic polystyrene film

[0047] 0.025g modified SiO 2 The particles are placed in a solution of 0.75g polystyrene (weight average molecular weight: 350,000) and 7.5g tetrahydrofuran, and after being fully dispersed in an ultrasonic pool for tens of hours, electrospinning is carried out by electrospinning equipment to obtain polystyrene / dioxide A superhydrophobic polystyrene film reinforced by nano-silica particles with a composite structure of silicon porous microspheres and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com