U-shaped steel-wood composite beam as well as supporting system and construction method thereof

A technology of support system and construction method, applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problems of natural environment damage, increase construction cost, affect construction quality, etc., to reduce Labor intensity, flexible use, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one, see Figure 5 As shown, the U-shaped steel-wood composite beam support system is used for roof formwork construction, and the steps are as follows:

[0041] Step 1, use the bowl buckle frame to erect the main keel 8, the main keel can be 50×100mm square steel;

[0042] Step 2, evenly laying U-shaped steel-wood composite beams 7 on the main keel with a spacing of 300-350 mm.

[0043] Step 3, laying a bottom formwork 9 above the U-shaped steel-wood composite beam, and constructing a concrete floor 11 on the bottom formwork 9.

[0044] The length specification of the U-shaped steel-wood composite beam is 0.5m as the modulus, ranging from 2m to 4m, and different lengths are selected according to the headroom size of the room. The lap length should be greater than 500mm, and the cantilever length should not be greater than 500mm.

Embodiment 2

[0045] Embodiment two, see Image 6 As shown, the U-shaped steel-wood composite beam support system is used for beam formwork construction, and the steps are as follows:

[0046] Step 1, build the main keel 8 on the supporting frame 10, the main keel may be 90×90mm, and the spacing may be 600mm.

[0047] Step 2, evenly laying U-shaped steel-wood composite beams 7 on the main keel 8, and laying a bottom template 9 on the U-shaped steel-wood composite beams 7;

[0048] Step 3, tie beam reinforcement, place formwork 15 on both sides, set U-shaped steel-wood composite beam 7 on the outside of side formwork 15, and fix it with back corrugated 13 and cross-piercing bolt 14;

[0049] Step 4, pouring concrete.

Embodiment 3

[0050] Embodiment three, see Figure 7 As shown, the U-shaped steel-wood composite beam support system is used for column formwork construction, and the steps are as follows:

[0051]Step 1, support four side formworks 15, and the above-mentioned side formworks 15 can be multi-layer boards with a thickness of 15 mm. Evenly lay U-shaped steel-wood composite beams 7 outside the side formwork 15, the spacing can be 300mm, and be fixed with the side formwork 15 by screws;

[0052] Step 2, fixing with column hoop 16 on the periphery of U-shaped steel-wood composite beam 7;

[0053] Step 3, pouring concrete.

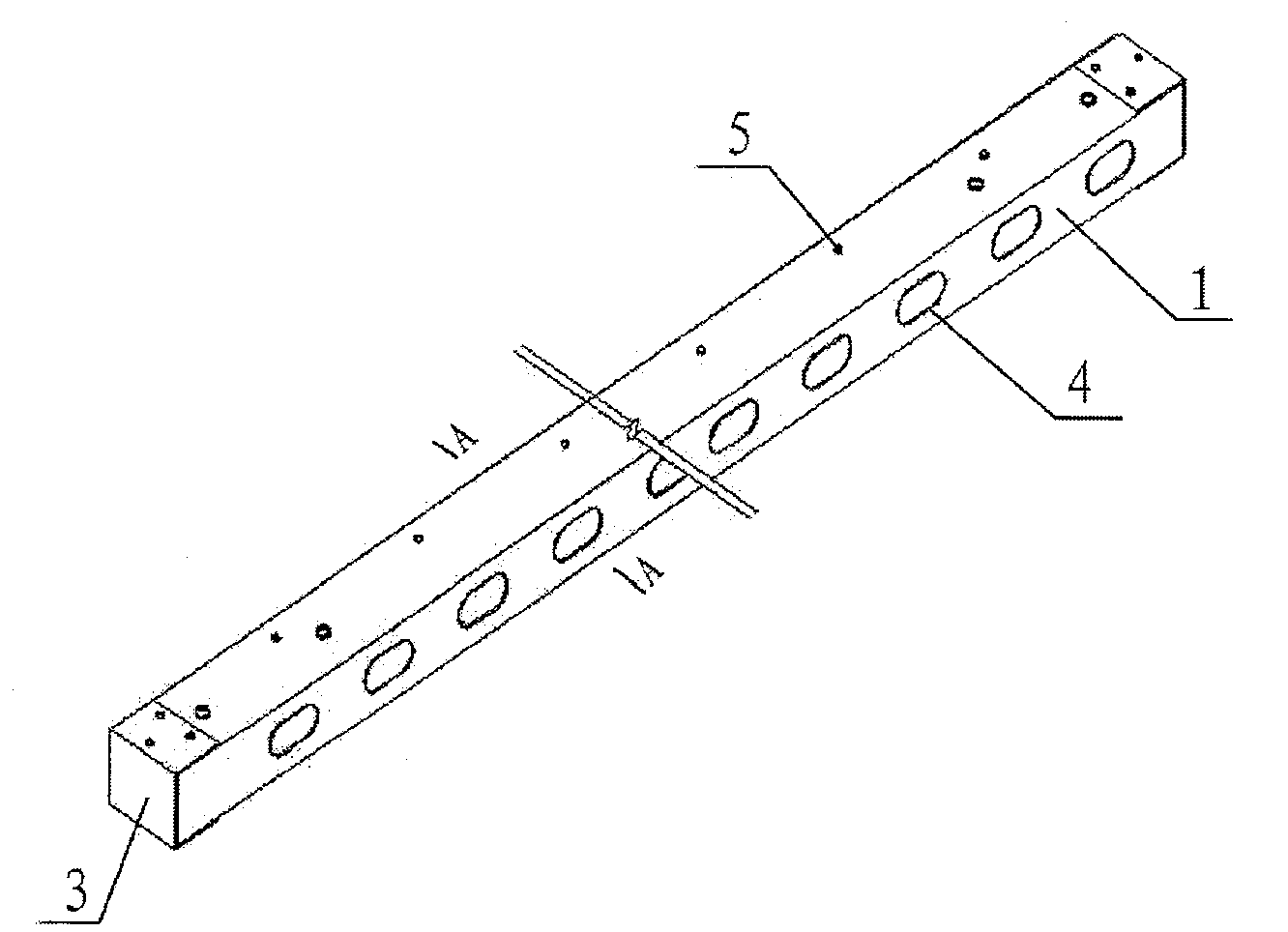

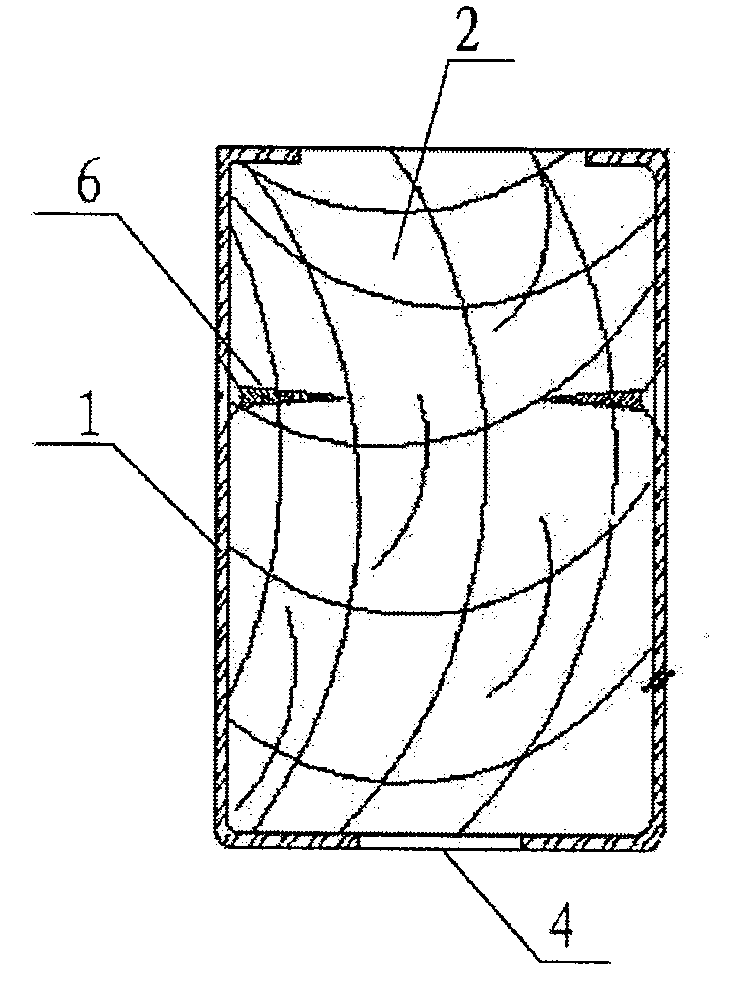

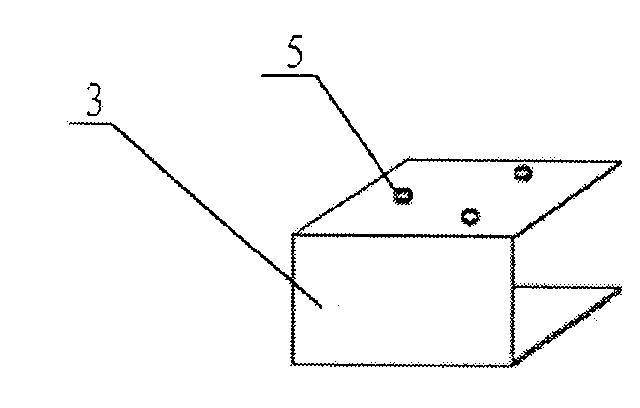

[0054] see Figure 4 As shown, when the length of the above-mentioned U-shaped steel-wood composite beam is not enough, it can be extended with a rectangular or U-shaped connecting plate 12, which has a perforation 13 on the connecting plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com