Bearing unit for railway carriages

A technology for bearing devices and railway vehicles, which is applied in the direction of railway vehicles, bearings, roller bearings, etc., can solve the problems of difficulty in manufacturing and assembling bearing devices, increasing the number of components, and deterioration of lubricants, etc., and achieves easy maintenance and management, manufacturing and assembling Ease, the effect that assemblability improves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

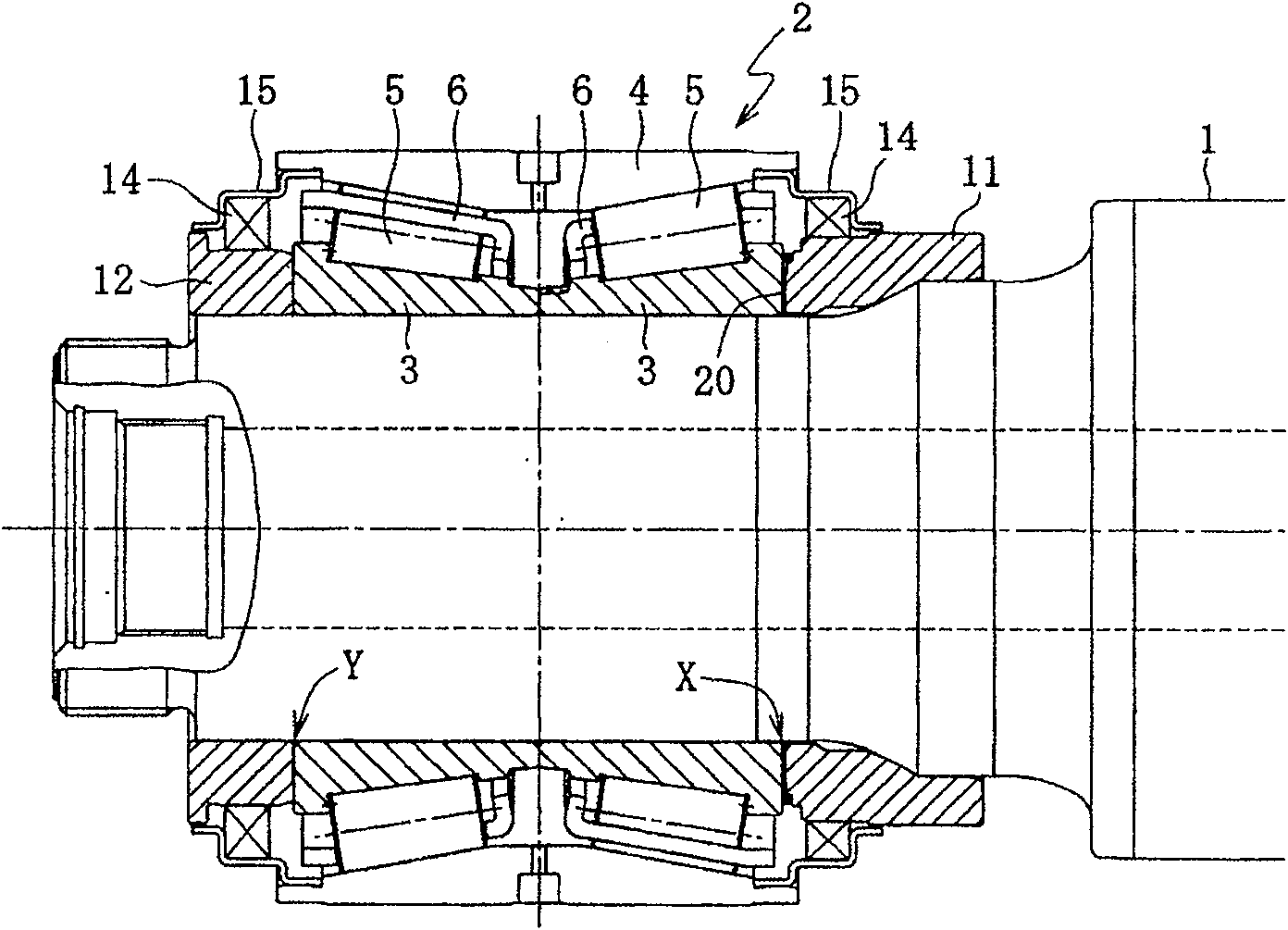

[0052] Hereinafter, the first embodiment will be described in order with reference to FIGS. 1 to 3. The basic structure of the bearing device for railway vehicles of this embodiment and Figure 5 The bearing device is the same, so for the Figure 5 The same or equivalent parts are marked with the same symbols to avoid repetitive explanations.

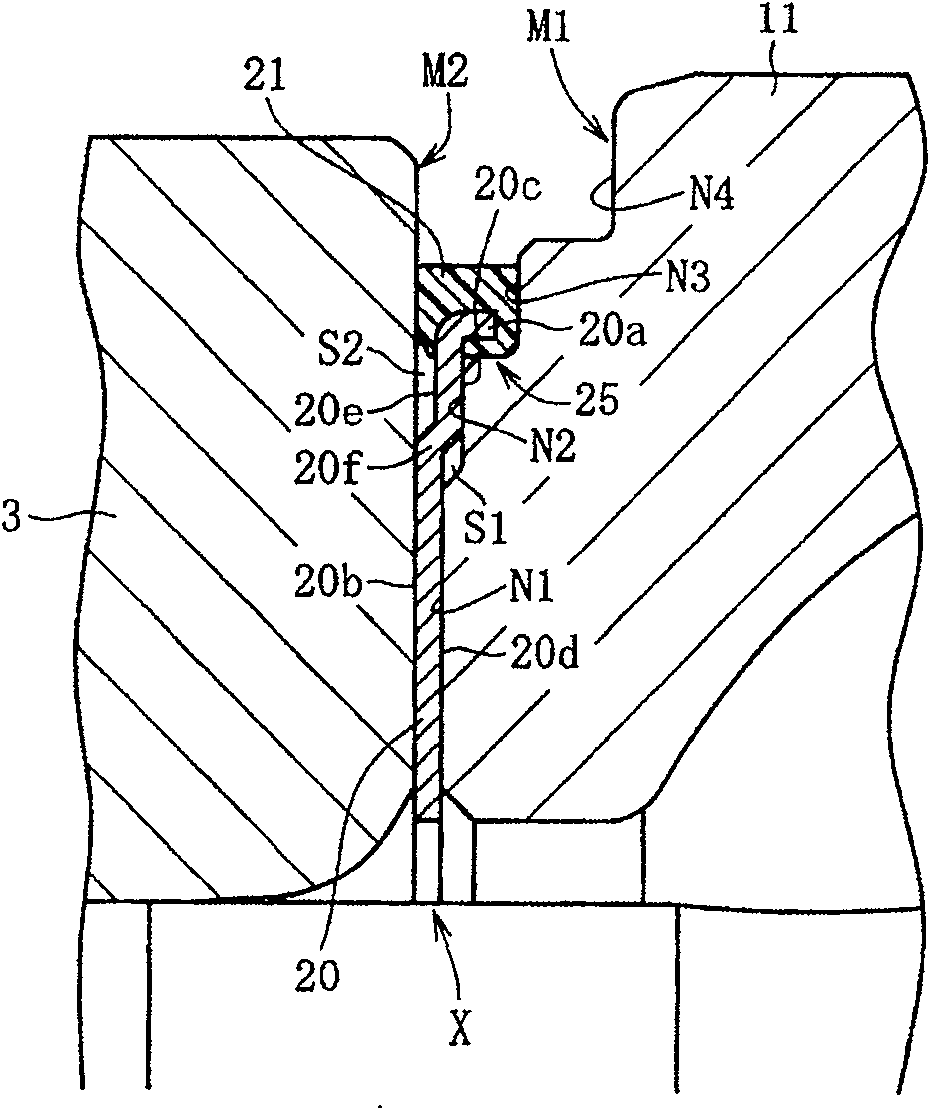

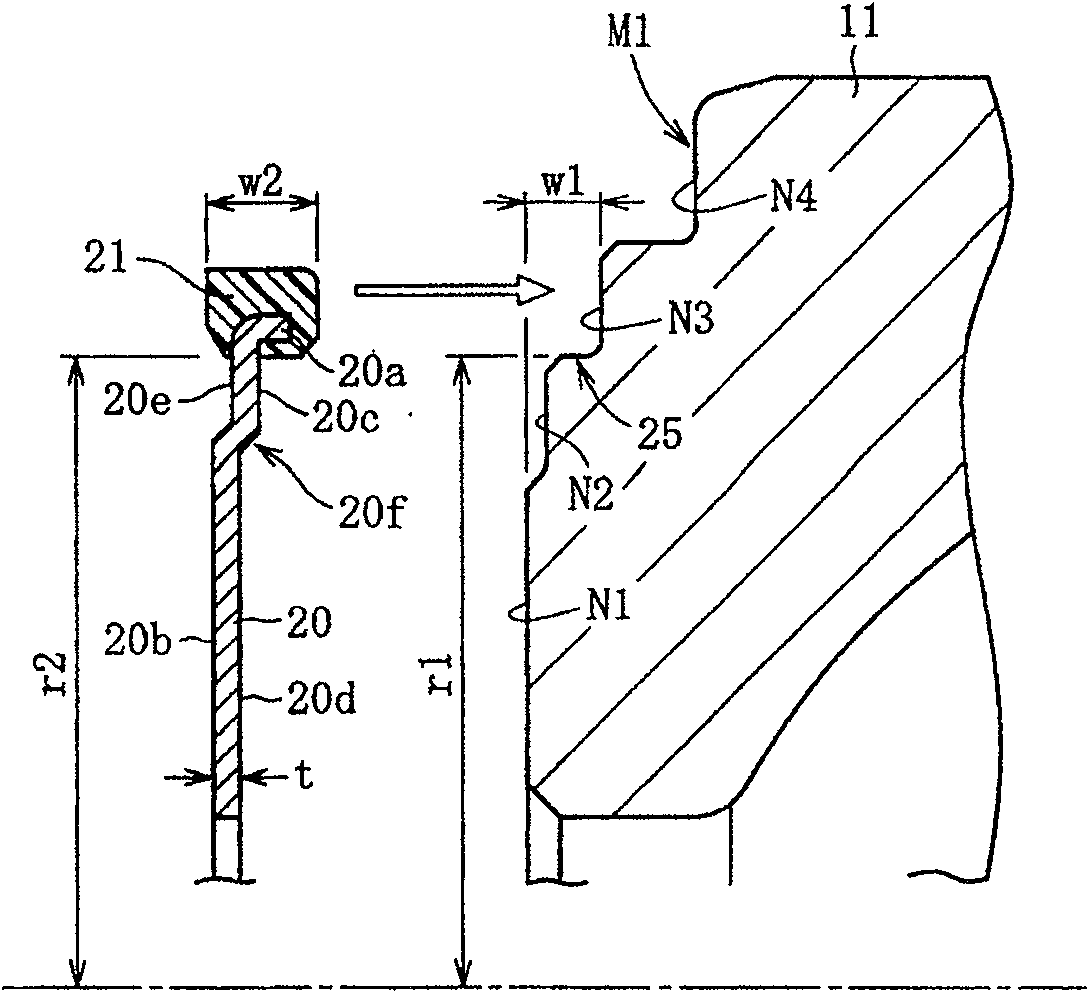

[0053] In the first embodiment shown in FIGS. 1(A) and (B), a ring-shaped partition plate 20 with an elastic seal is sandwiched in the contact portion X between the inner wheel 3 and the rear cover 11 (circular member) , Both sides of the ring-shaped partition 20 abut the rear width of the inner wheel 3 and the front width of the rear cover 11. The ring-shaped partition 20 with elastic seal is an integral member in which an elastic seal 21 such as an annular rubber ring is integrally fixed to the outer peripheral edge of the partition 20 of a circular ring-shaped brass thin plate.

[0054] The ring-shaped partition 20 is made of a press-for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com