Exhaust gas purifying device for spray painting workshop

A waste gas purification device and workshop technology, applied to the surface coating liquid device, combined device, application, etc., can solve the problems of large pollutant particles, inability to purify air, and air environment pollution, and achieve good purification effect without causing pollution. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

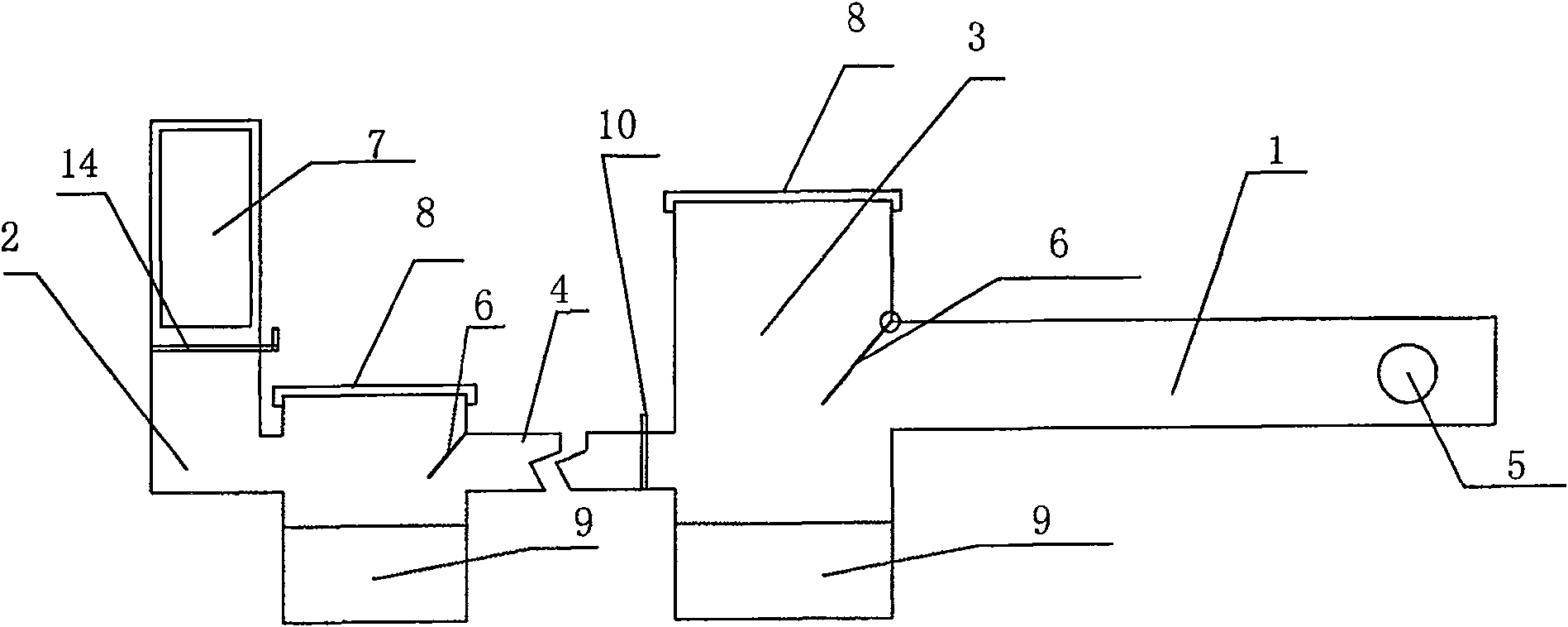

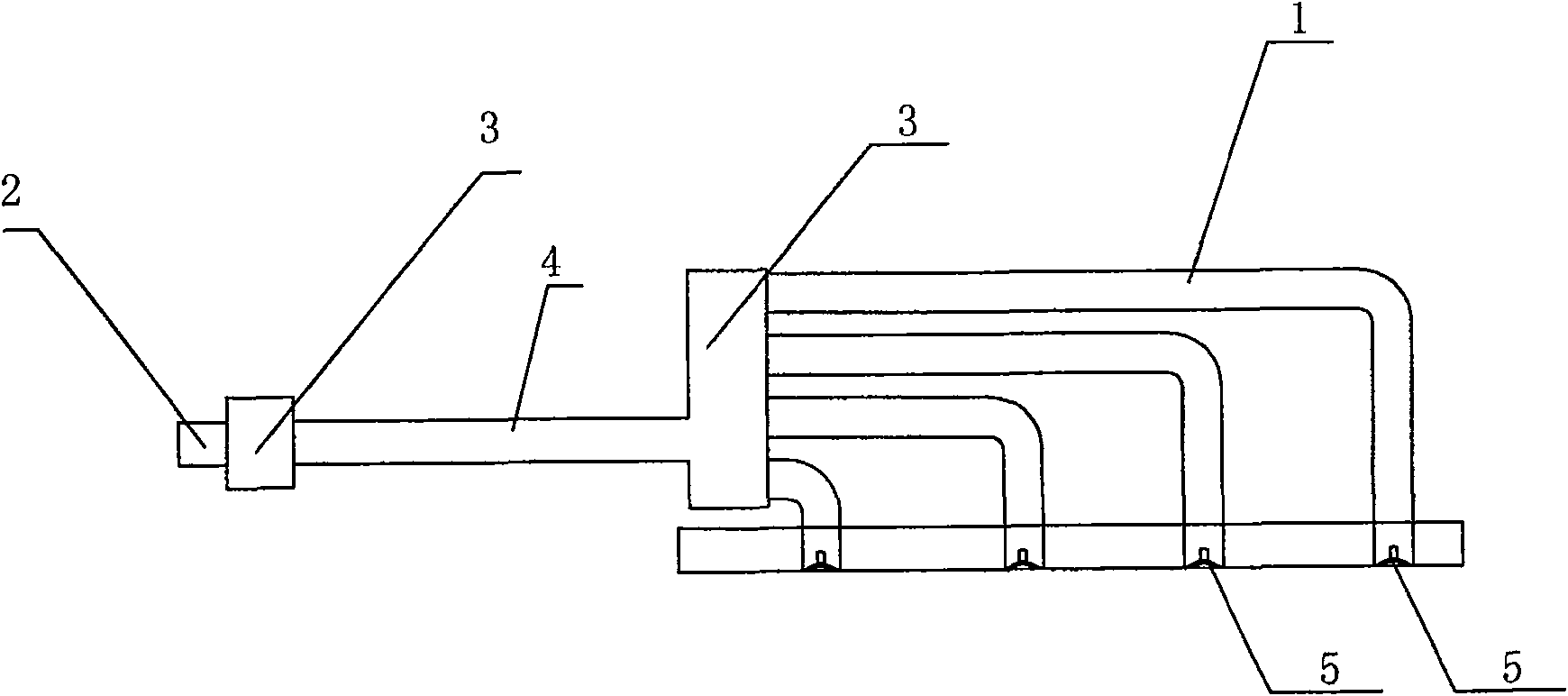

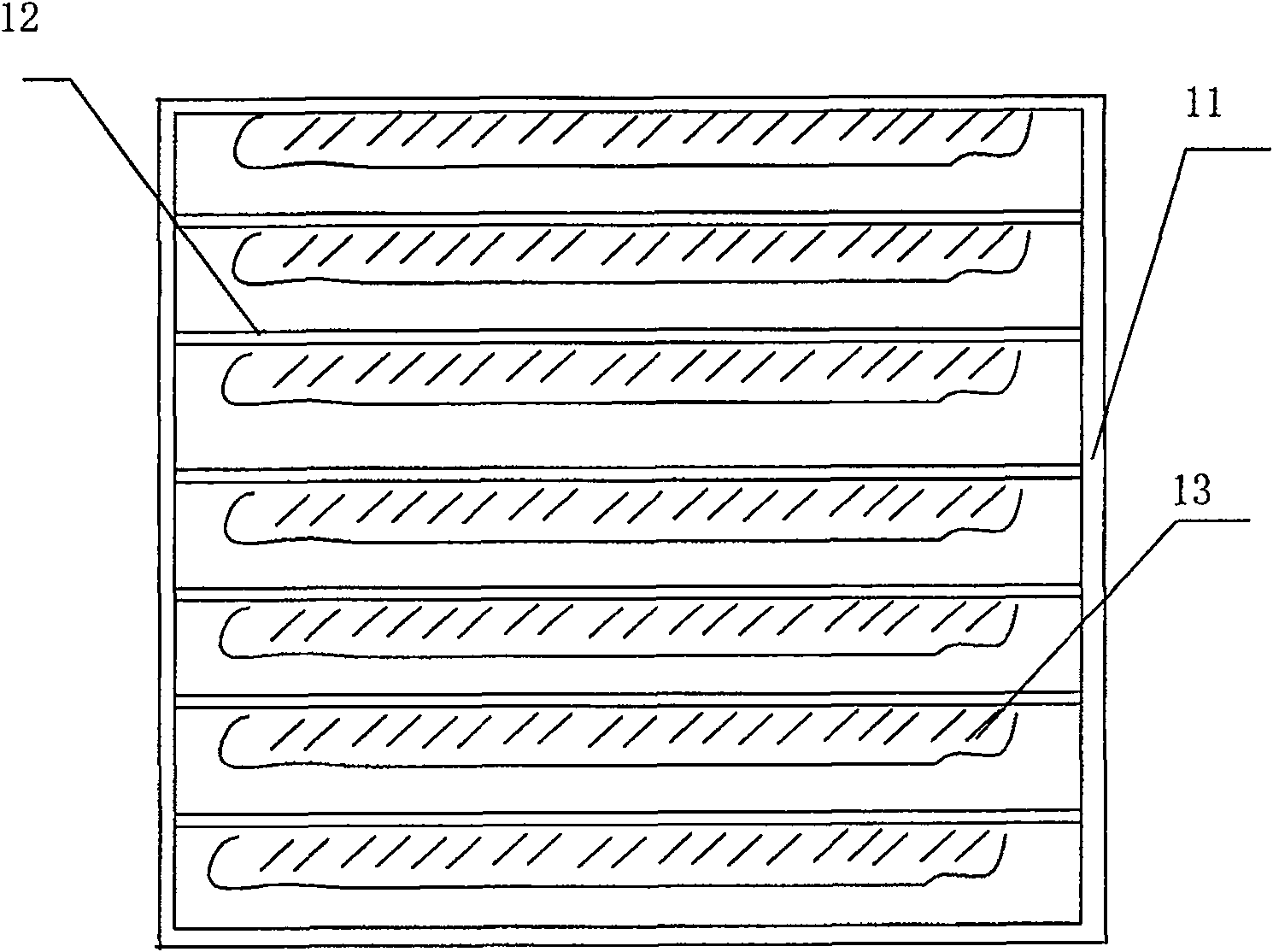

[0019] An exhaust gas purification device for a painting workshop, comprising four air inlet pipes 1 and air outlet pipes 2, two clean rooms 3 are arranged between the air inlet pipes 1 and the air outlet pipes 2, and the air ducts 4 are arranged between the clean rooms 3 Connection, the air duct 4 is placed with a dust-absorbing curtain 10, the dust-absorbing curtain 10 includes a frame 11, a crosspiece 12 and a dust-absorbing cloth 13, the crosspiece 12 is arranged in the frame 11, and the dust-absorbing cloth 13 is hung on the crosspiece 12 Above, the end of the air inlet pipe 1 corresponding to the painting station is provided with an exhaust fan 5, and the other end of the air inlet pipe 1 communicates with the clean room 3, and the air inlet of the clean room 3 is provided with a wind board 6, and the air board 6 The upper end of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com