Production technology of orange wine

A production process, the technology of Guanggan, which is applied in the field of deep processing of Guanggan, can solve the problems of poor taste, less production equipment, and low manufacturing cost, and achieve the effects of high yield, full-bodied and mellow wine, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

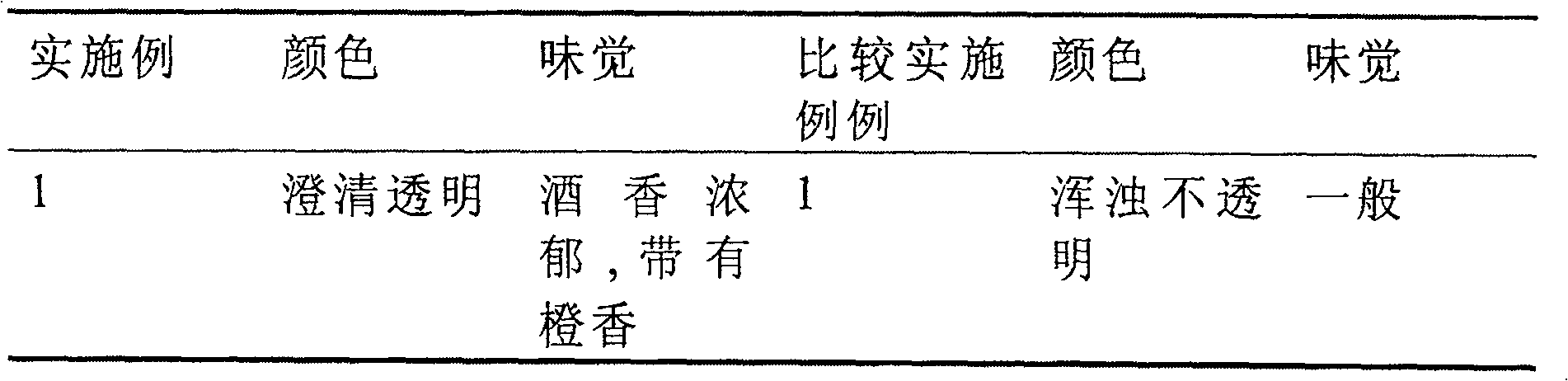

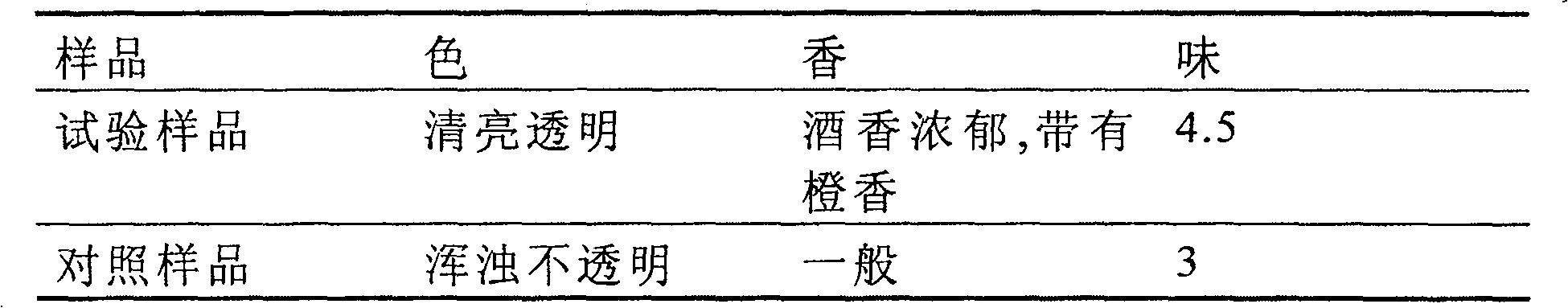

Embodiment 1

[0037] 1: Preparation of Cantonese Fruit Wine

[0038] Clean the oranges selected above: wash the impurities and dirt on the surface of the fruit, disinfect the fruit after washing, soak in 0.3% Na2CO3 solution for 4 minutes, rinse with water to remove Na 2 CO 3 Drain and set aside, use 0.03% bleaching powder to sterilize and add medicine, then stir well to clean the fruit.

[0039]Peel off the outer skin of the orange fruit, peel off the sponge layer (i.e. the second layer of skin of the orange) for additional processing into white wine; peel off the skin of the meat, take out the meat and rice juice cells and beat it into broken rice juice;

[0040] Put the above-mentioned crushed juice into a container, and the container should be inspected to ensure no pollution, no air leakage, clean and dry; in order to avoid expansion and rupture of the container cylinder during fermentation, it can only be filled no more than 4 / 5 The amount of sterilized, refined and dried new nylon ...

Embodiment 2

[0069] The time of natural fermentation is 9 months, the fermentation temperature is 40 ℃, the liquor concentration of the Cantonese brandy obtained in the first stage is 30%, the liquor concentration of the obtained Cantonese brandy in the second stage is 45%, and the liquor concentration of the obtained Cantonese brandy in the second stage is 45%. The liquor concentration of Cantonese brandy is 60%; Others are with embodiment 1.

Embodiment 3

[0071] The time of natural fermentation is 12 months, the fermentation temperature is 25 ℃, the liquor concentration of the Cantonese brandy obtained in the first stage is 38%, the liquor concentration of the obtained Cantonese brandy in the second stage is 58%, and the liquor concentration of the obtained Cantonese brandy in the second stage is 58%. The liquor concentration of Cantonese brandy is 70%; Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com