Polyacryl-nitrile spinning fluid containing glyoxaline salt and method of producing the same

A technology for spinning polyacrylonitrile and containing imidazolium salt is applied in the field of polyacrylonitrile-based carbon fiber spinning solution and its preparation to achieve the effects of improving spinnability, improving hydrophilicity and promoting spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

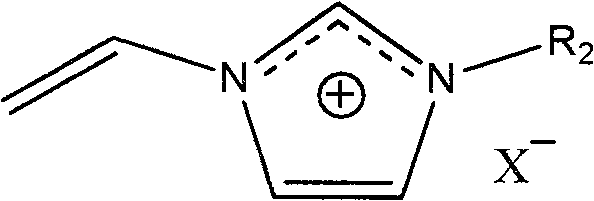

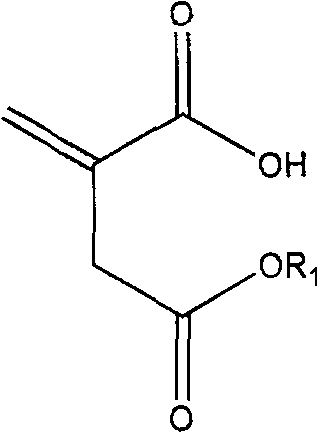

[0029] Solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer VinBuIm + Br - And β-MMI, azobisisobutyronitrile, a free radical initiator, is added to the reactor with a condenser and a mechanical stirring device. The weight percentage proportioning of added raw material is: main monomer acrylonitrile is 98% of monomer gross weight, comonomer VinBuIm + Br - 1% of the total monomer weight, comonomer β-MMI is 1% of the total monomer weight, and the consumption of azobisisobutyronitrile is 0.5% of the total monomer weight, and the total monomer concentration (percentage by weight) is 20%. The mixture was stirred and mixed at room temperature. After bubbling nitrogen for 20 minutes, under the protection of nitrogen, it was reacted at a constant temperature of 60° C. for 24 hours, and then residual monomers and bubbles were removed to obtain a polyacrylonitrile spinning solution containing imidazolium salt. The weight-average molecular weight of the copolymer is 242,0...

Embodiment 2

[0031] Solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer ViEtIm + Br - And β-MEI, the free radical initiator azobisisobutyronitrile, was added to the reactor with a condenser and a mechanical stirring device. The weight percentage proportioning of added raw material is: main monomer acrylonitrile is 90% of monomer gross weight, comonomer ViEtIm + Br - Be 5% of monomer gross weight, comonomer β-MEI is 5% of monomer gross weight, the consumption of azobisisobutyronitrile is 0.5% of monomer gross weight, monomer gross concentration (percentage by weight) is 20%. The mixture was stirred and mixed at room temperature. After bubbling nitrogen for 20 minutes, under the protection of nitrogen, it was reacted at a constant temperature of 60° C. for 24 hours, and then residual monomers and bubbles were removed to obtain a polyacrylonitrile spinning solution containing imidazolium salt. The weight-average molecular weight of the copolymer is 109,000, the molecular wei...

Embodiment 3

[0033] Solvent dimethyl sulfoxide, main monomer acrylonitrile, comonomer ViMeIm + Cl - And β-MPI, a free radical initiator azobisisobutyronitrile, is added to the reactor with a condenser and a mechanical stirring device. The weight percent proportioning of added raw material is: main monomer acrylonitrile is 97% of monomer gross weight, comonomer ViMeIm + Cl - 1% of the total weight of the monomers, comonomer β-MPI is 2% of the total weight of the monomers, and the consumption of azobisisobutyronitrile is 0.5% of the total weight of the monomers, and the total concentration of the monomers (percentage by weight) is 25%. The mixture was stirred and mixed at room temperature. After bubbling nitrogen for 20 minutes, under the protection of nitrogen, it was reacted at a constant temperature of 65° C. for 24 hours, and then residual monomers and bubbles were removed to obtain a polyacrylonitrile spinning solution containing imidazolium salt. The weight-average molecular weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com