Energy-saving insulating brick

A technology for thermal insulation bricks and brick products, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of cumbersome construction of energy-saving thermal insulation measures, long construction period and high cost, and achieve long-term effective thermal insulation effect, The effect of shortened construction period and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is carried out according to the following steps: at normal temperature, various raw materials are sequentially put into the JSC500C mixer according to the ratio of weight and number of parts, and vigorously stirred for 90 seconds to 120 seconds; In the forming mold of the brick machine, press, the working pressure is 3MPa, and then press through vibration until the insulation brick is formed; then perform steam curing for 13 hours to 15 hours, and the steam curing temperature is 85°C-95°C, so that the formed insulation brick The strength of the finished product is raised to 70% of the design strength, and then sent to the finished product storage yard.

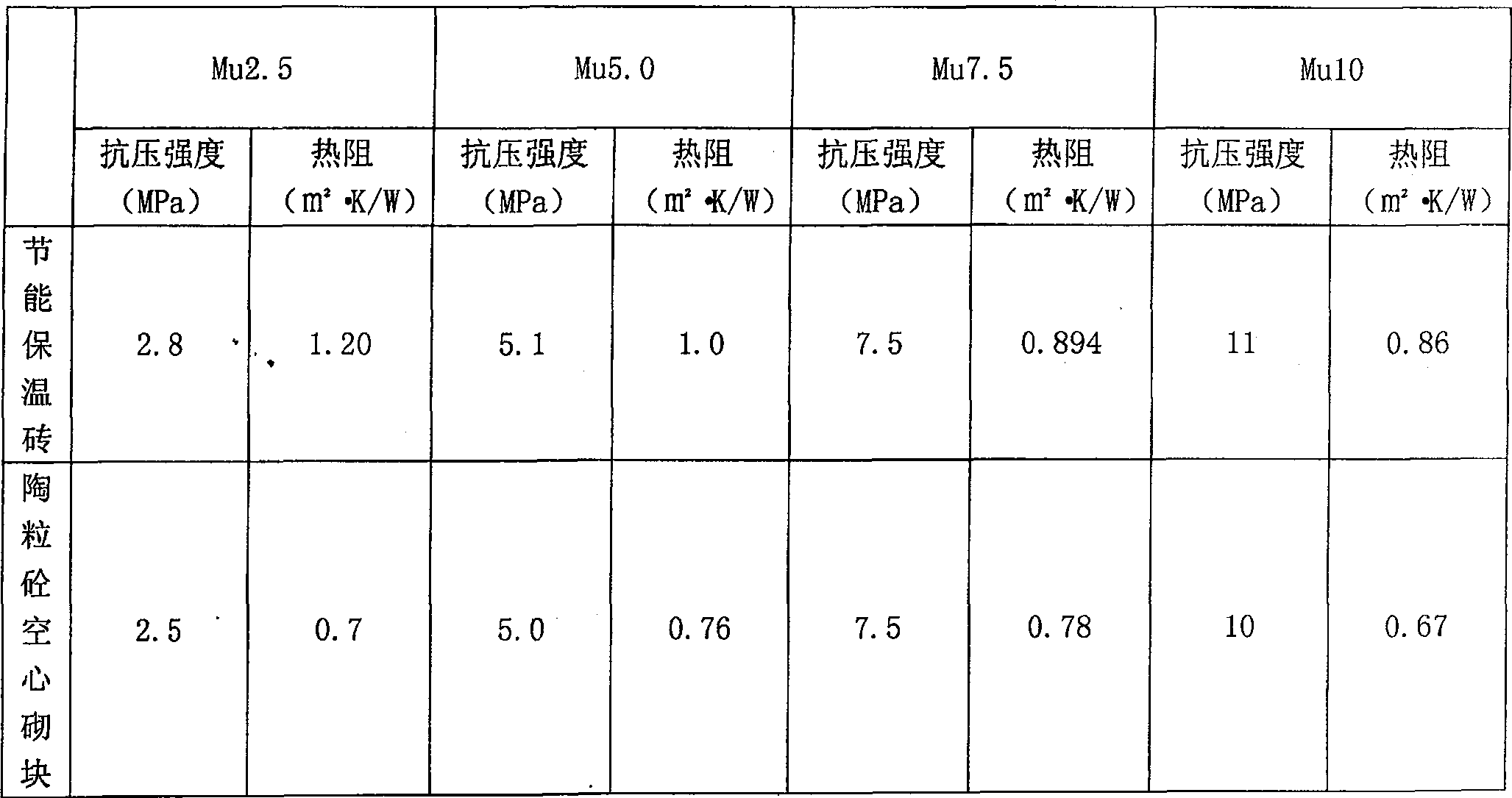

[0016] See Table 1 for the parts by weight of raw materials in Examples 1 to 4, and the unit is kilogram.

[0017] Table 1

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com